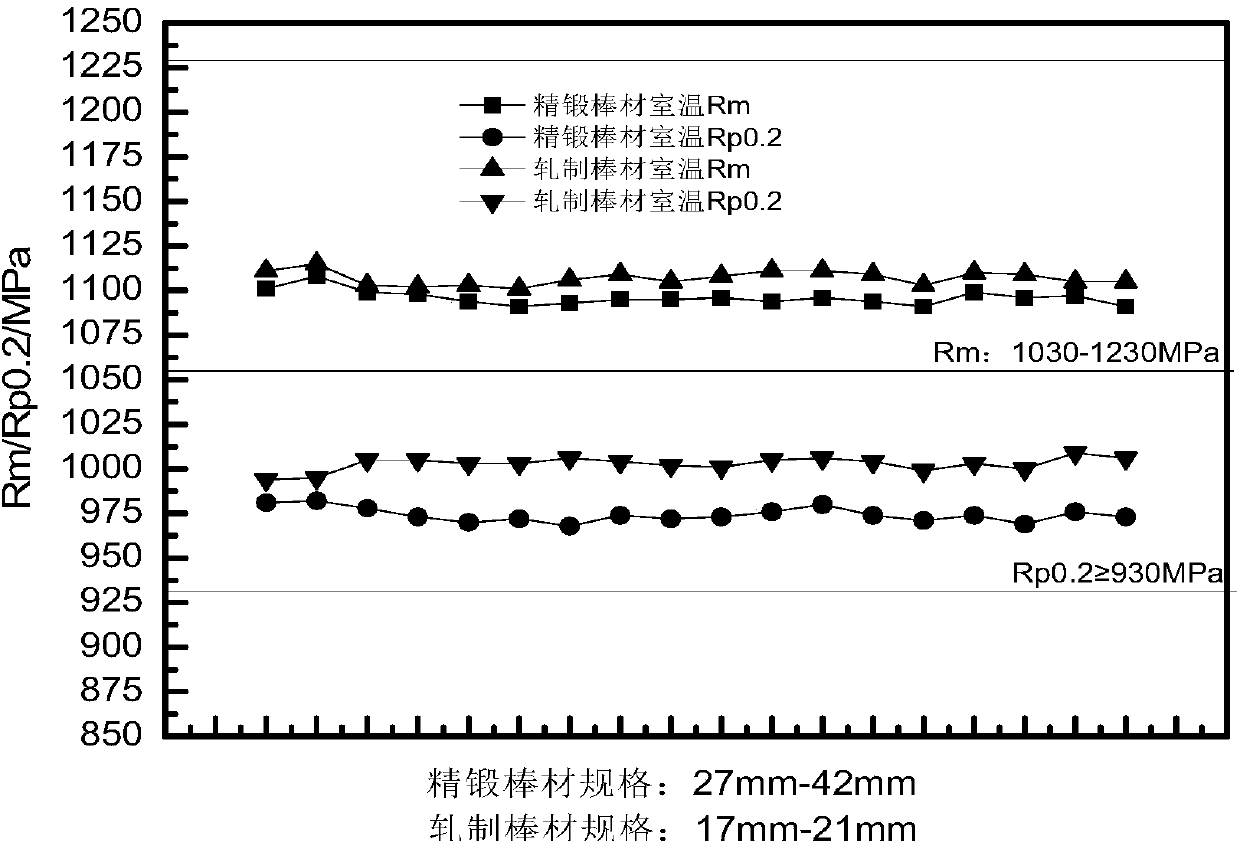

Preparing method of high-uniformity TC11 alloy bar for blade

A technology of TC11, alloy bar, applied in the field of titanium alloy processing, can solve the problem of uneven structure of TC11 alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1, one-fire precision forging of the bar:

[0033] A typical two-state structure obtained by high-temperature billet forging at 150°C to 200°C above the phase transition point and full forging deformation in the two-phase region at 40°C to 80°C below the phase transition point, in which the primary α is spherical and contains more than 60% of TC11 Titanium alloy Φ85mm precision forging billet, heated at 40℃~80℃ below the phase transition point, using SKK-10 precision forging machine for one-fire precision forging to Φ55mm intermediate precision forging blank, the precision forging pass is 5 passes, and each pass deforms Amount of 15%;

[0034] Step 2, the homogenization of the intermediate billet:

[0035] Place the intermediate precision forging billet obtained in step 1 in a box-type heat treatment resistance furnace, heat it at 40°C to 80°C below the phase transition point, carry out air firing for 60 minutes, and then air cool it to improve the structure unifo...

Embodiment 2

[0041] Step 1, one-fire precision forging of the bar:

[0042] It is a typical two-state structure obtained by high-temperature billet forging at 150°C to 200°C above the phase transition point and full forging deformation in the two-phase region at 40°C to 80°C below the phase transition point, in which the primary α is spherical and the content is greater than 60%. TC11 titanium alloy Φ95mm precision forging billet, heated at 40℃~80℃ below the phase transition point, using SKK-10 precision forging machine for one-fire precision forging to Φ65mm intermediate precision forging billet, the precision forging pass is 5 passes, each pass The amount of deformation is 15%;

[0043] Step 2, the homogenization of the intermediate billet:

[0044] Place the intermediate precision forging billet obtained in step 1 in a box-type heat treatment resistance furnace, heat it at 40°C to 80°C below the phase transition point, carry out air firing for 60 minutes, and then air cool it to improv...

Embodiment 3

[0051] Step 1, one-fire precision forging of the bar:

[0052] It is a typical two-state structure obtained by high-temperature billet forging at 150°C to 200°C above the phase transition point and full forging deformation in the two-phase region at 40°C to 80°C below the phase transition point, in which the primary α is spherical and the content is greater than 60%. TC11 titanium alloy Φ85mm precision forging billet, heated at 40℃~80℃ below the phase transition point, using SKK-10 precision forging machine for one-fire precision forging to Φ45mm intermediate precision forging blank, the precision forging pass is 5 passes, each pass The amount of deformation is 15%;

[0053] Step 2, the homogenization of the intermediate billet:

[0054] Place the intermediate precision forging billet obtained in step 1 in a box-type heat treatment resistance furnace, heat it at 40°C to 80°C below the phase transition point, perform air firing for 40 minutes, and then air cool it to improve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com