Filling pile construction scheme and funnel thereof

A technology of cast-in-situ piles and funnels, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as troubles, and achieve the effect of convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

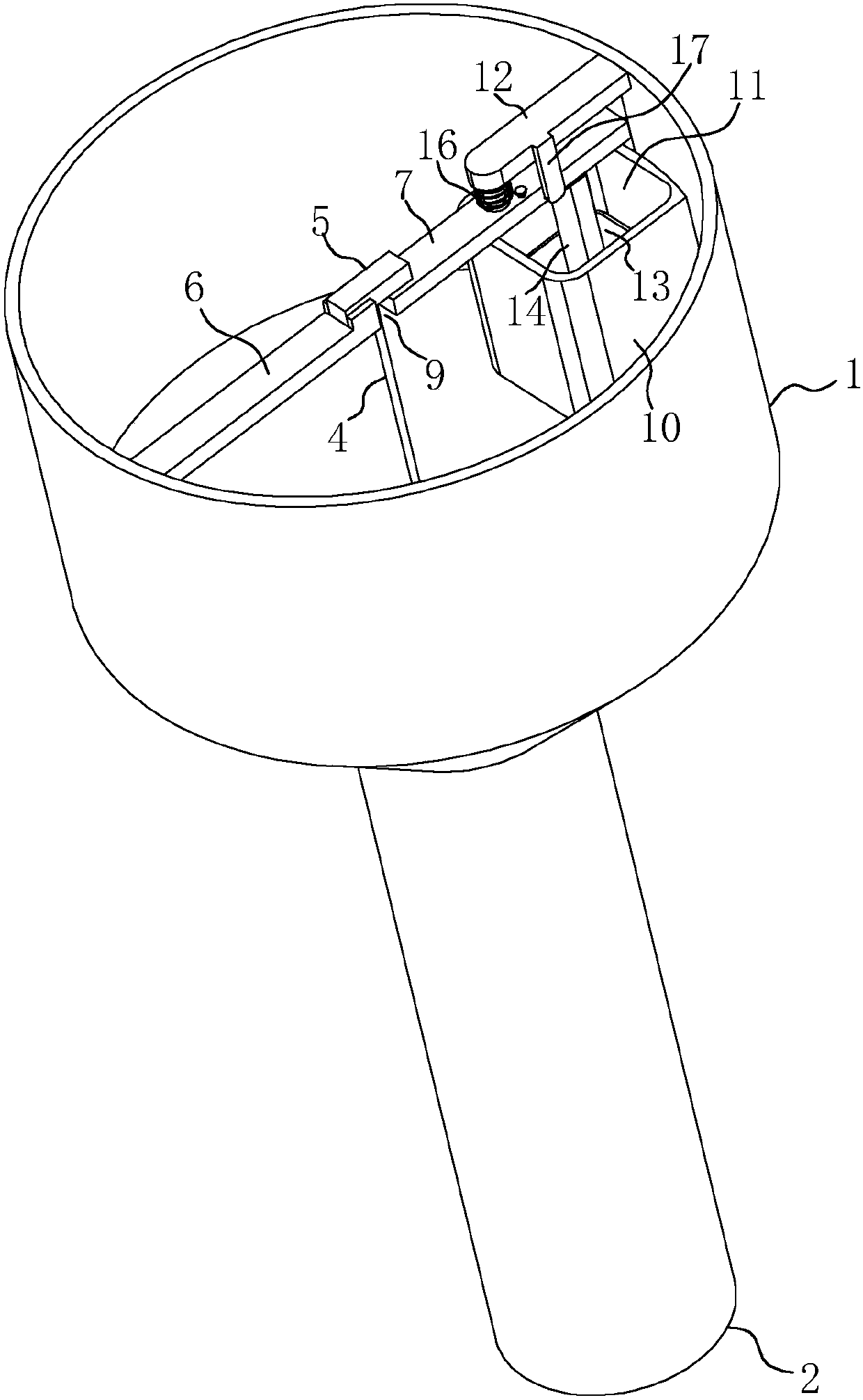

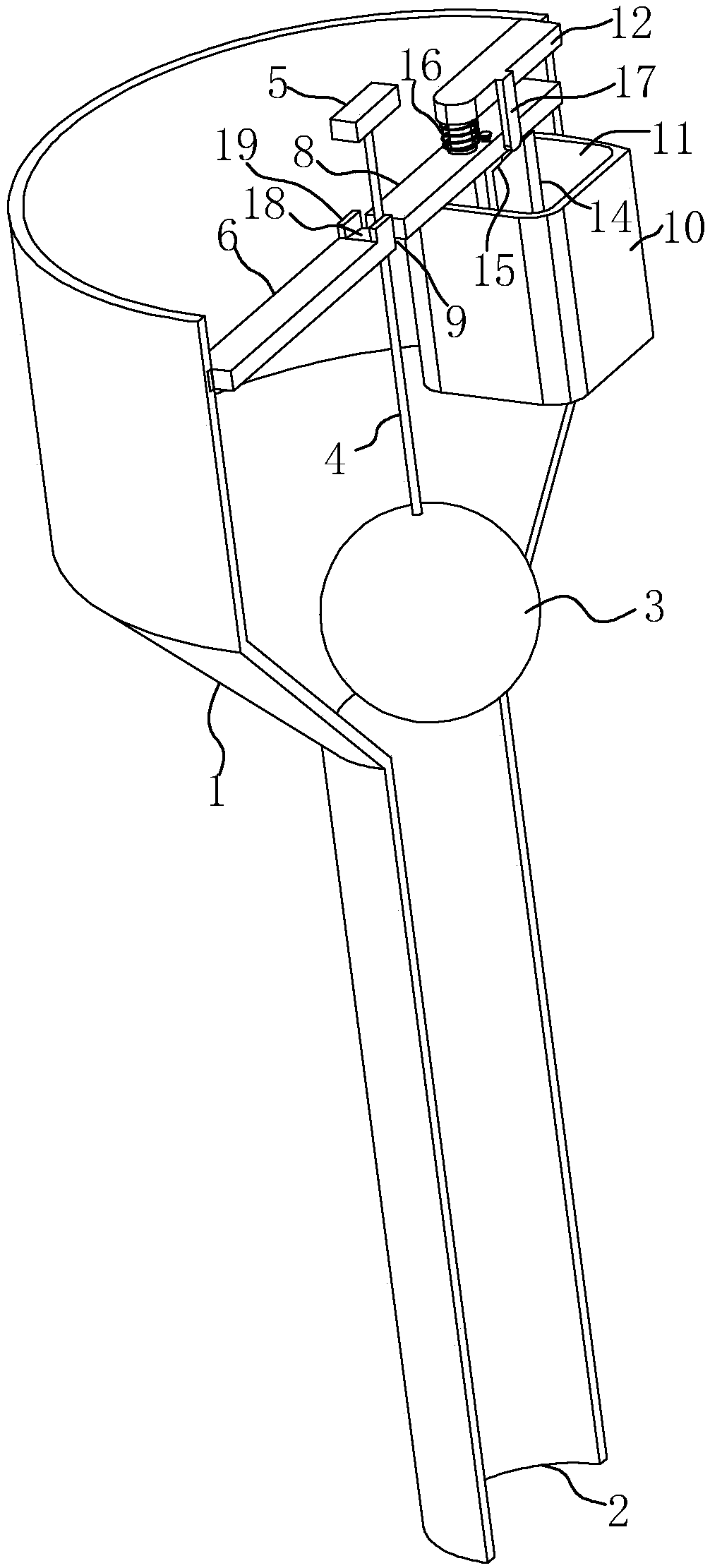

[0040] Embodiment 1: the funnel that is used for cast-in-situ pile construction, as figure 1 and figure 2 As shown, a bucket body 1 is included, an outlet 2 is arranged at the bottom of the bucket body 1, and a cross bar is arranged radially on the top of the bucket body 1, and a ball 3 adapted to the outlet 2 is hoisted on the cross bar, and the ball 3 A suspension rope 4 is fixed on the top, and a block body 5 is fixed on the top of the suspension rope 4, wherein the crossbar includes a fixed rod 6 and a movable rod. The middle part of the rotating rod 7 is rotatably connected to the protruding bar 12, there is a gap 9 between the movable rod and the end of the rotating rod 7 for the passage of the hanging rope 4, and the block 5 is placed on the fixed rod 6 and the rotating rod 7 to realize hoisting In this way, the outlet 2 is blocked by means of the ball 3 so that the concrete added to the bucket body 1 will not leak immediately; in addition, a coaming plate 10 is provi...

Embodiment 2

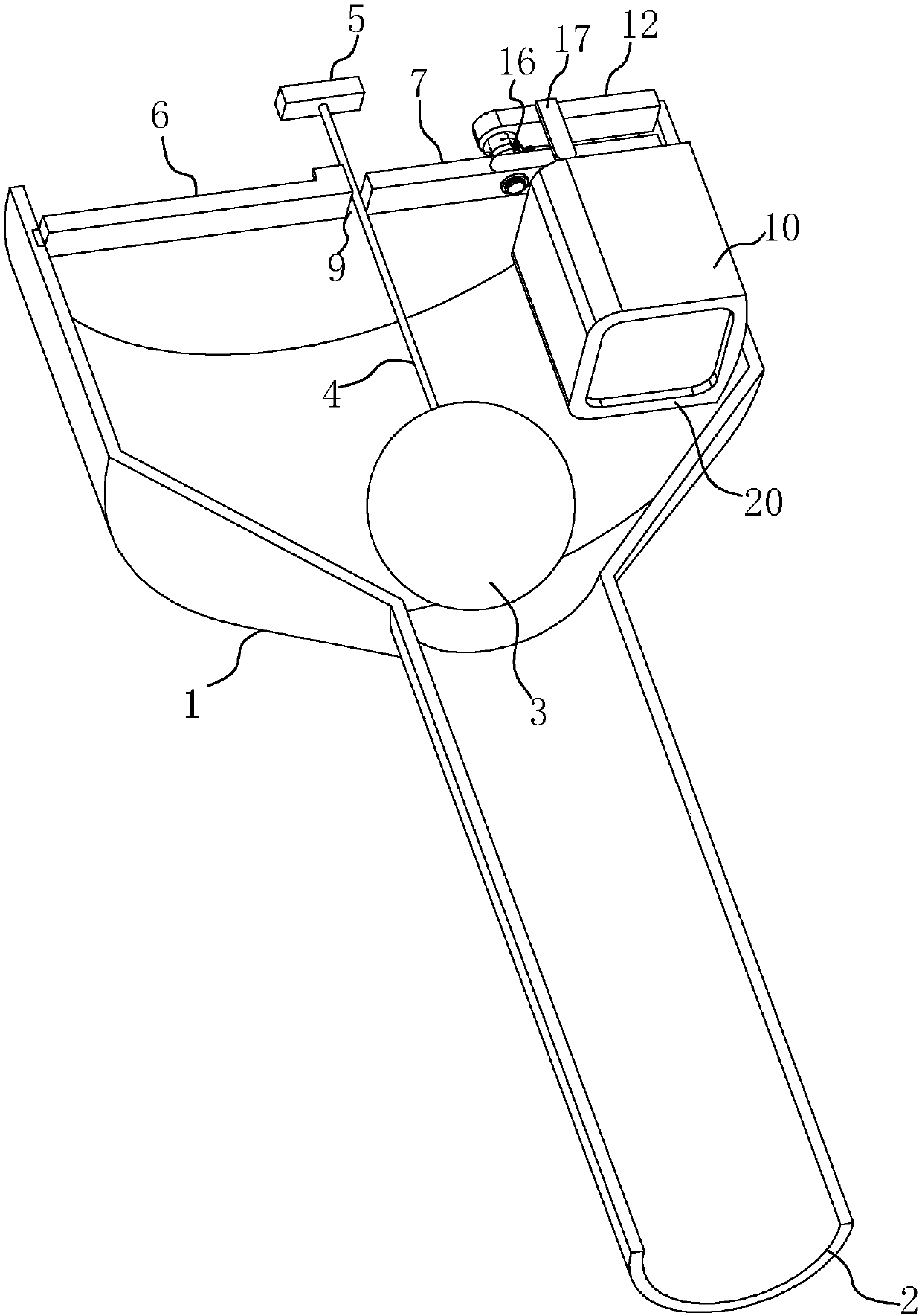

[0044] Embodiment 2: the funnel that is used for cast-in-situ pile construction, as Figure 4 and Figure 5 As shown, the difference between it and Embodiment 1 is that the movable rod is a sliding rod 8, and the sliding rod 8 is horizontally slidably connected to the bucket body 1, and the linkage mechanism therein includes a vertical rod 21 fixed on the floating block 13, and at the same time The bottom of the slide bar 8 is fixed with a projection 22, and the top of the vertical bar 21 is provided with a second wedge-shaped surface 24 that abuts against the projection 22 and drives the slide bar 8 to move away from the fixed bar 6, so that the end of the slide bar 8 part no longer supports the block body 5 to realize the falling and discharging of the block body 5 and the sphere 3, wherein when the block body 5 is placed, the length of the block body 5 on the slide bar 8 is greater than the length on the fixed bar 6, so that The center of gravity of the block body 5 is bia...

Embodiment 3

[0046] Embodiment 3: cast-in-place pile construction scheme, as Figure 6 As shown, the specific process is as follows:

[0047] 1. Measurement and setting out

[0048] Establish a temporary construction control network: In order to ensure the accuracy of pile positioning, it is planned to use the methods of peripheral control network and on-site fixed-point control network for construction measurement and fixed-point;

[0049] ⑴Establish the peripheral control network: select the control axis according to the relationship between the axes of the construction drawings, and extend it to the outside of the construction site to establish a control point network, so that the measurement review can be carried out when the pile position is checked;

[0050] ⑵Establishment of on-site control network: due to the large staggered axes of this project, the off-site control network cannot fully determine the direction and fixed point of the axis, so it is necessary to establish a solid n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com