A prefabricated transmission tower body connection node and manufacturing method thereof

A technology for connecting nodes and transmission towers, which is applied in the field of connecting nodes of prefabricated concrete-filled steel tube transmission towers, which can solve problems such as insufficient rigidity and poor seismic performance, and achieve the effects of improved foundation stability, high bearing capacity, and increased stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

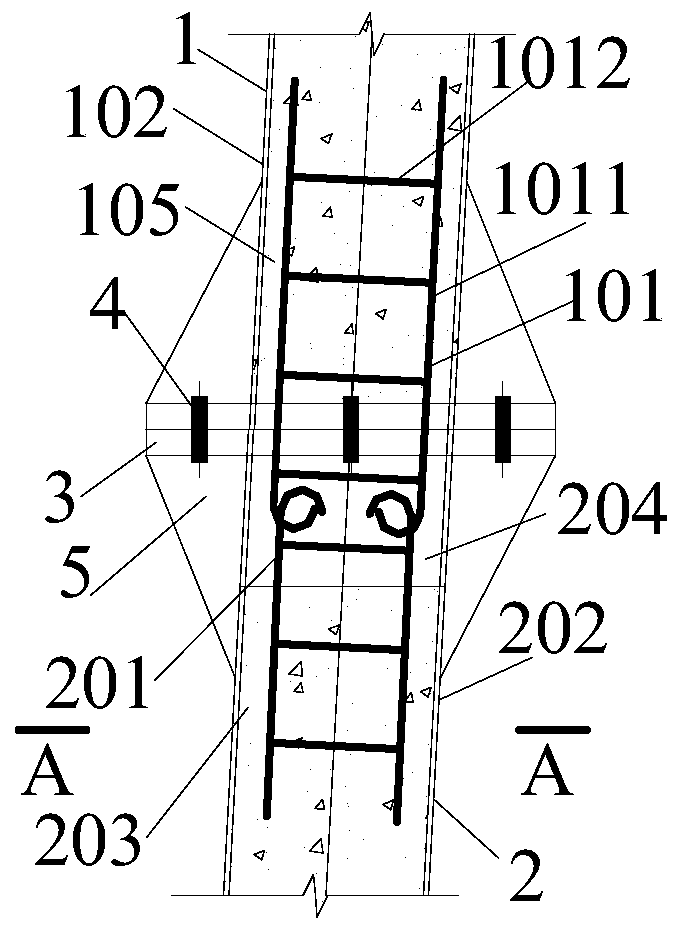

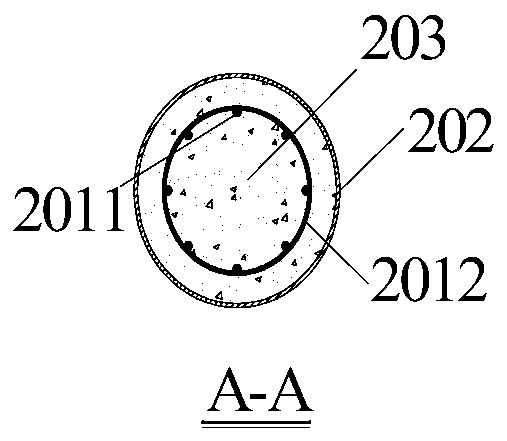

[0023] Such as figure 1 As shown, a prefabricated transmission tower body connection node includes an upper section of concrete filled steel pipe member 1 and a lower section of steel pipe concrete member 2. The steel pipe 202 is provided with an upper reinforcement cage 101 and a lower reinforcement cage 201 respectively; the upper outer steel pipe 102 is poured with an upper inner filling concrete 105, and the lower outer steel pipe 202 is poured with a lower inner filling concrete 203 and a post-cast concrete 204; the upper outer steel pipe The upper steel cage 101 provided inside the concrete member 1 extends into the lower steel pipe concrete member 2 and partially overlaps with one end of the lower steel cage 201 in the lower steel pipe concrete member 2 . Rigid flanges 3 are respectively welded to the cornice edges of the outer steel pipe 102 of the upper section and the outer steel pipe 202 of the lower section. A stiffening plate 5 is arranged between the outer steel...

Embodiment 2

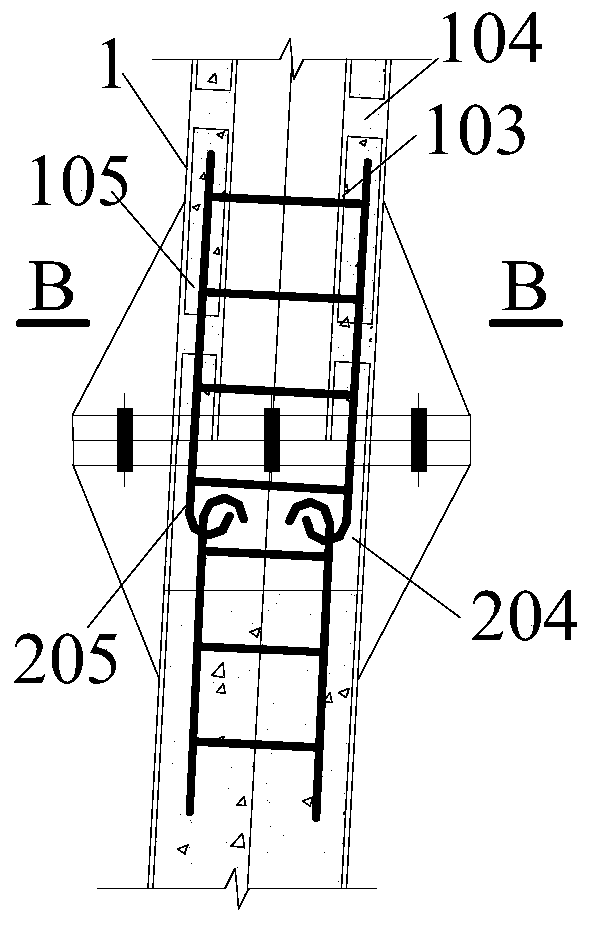

[0030] Such as figure 2As shown, a prefabricated transmission tower body connection node includes an upper section of concrete filled steel pipe member 1 and a lower section of steel pipe concrete member 2. The steel pipe 202 is provided with an upper reinforcement cage 101 and a lower reinforcement cage 201 respectively; the upper outer steel pipe 102 is fixedly connected with an inner steel pipe 103 through a connecting plate 104, and the upper reinforcement cage 101 is arranged between the upper outer steel pipe 102 and the inner steel pipe 103 The inner filling concrete 105 of the upper section is poured in it, the inner filling concrete 203 of the lower section and the post-casting concrete 204 are poured in the outer steel pipe 202 of the lower section; It partially overlaps with one end of the lower reinforcement cage 201 in the lower concrete-filled steel tube member 2 . Rigid flanges 3 are respectively welded to the cornice edges of the outer steel pipe 102 of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com