Construction method of subgrade widening structure

A construction method and roadbed technology, which is applied in roads, roads, buildings, etc., can solve the problems that the compactness cannot meet the design standard, the new and old roadbeds are complicated in technology, and the construction is difficult, so as to improve the stability of the foundation and simplify the construction process. , The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

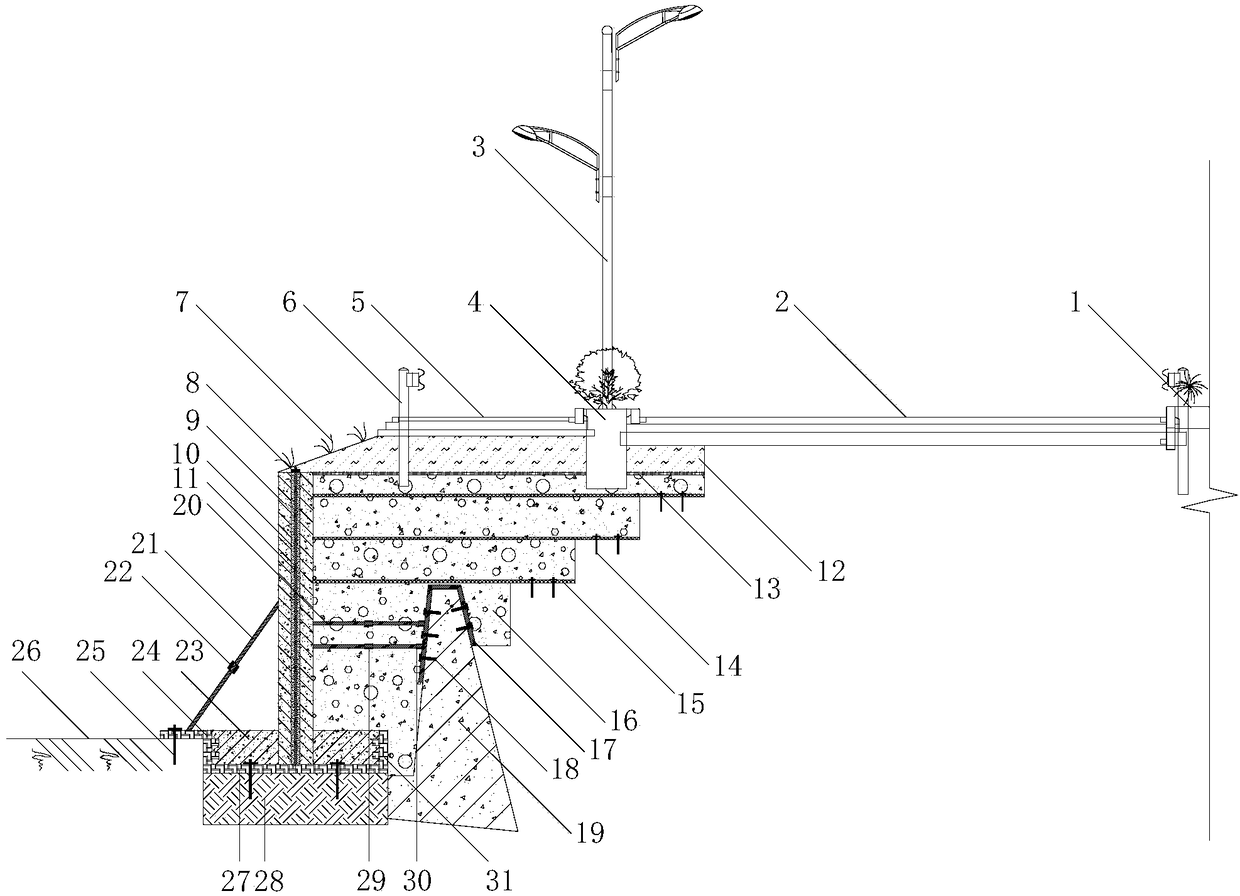

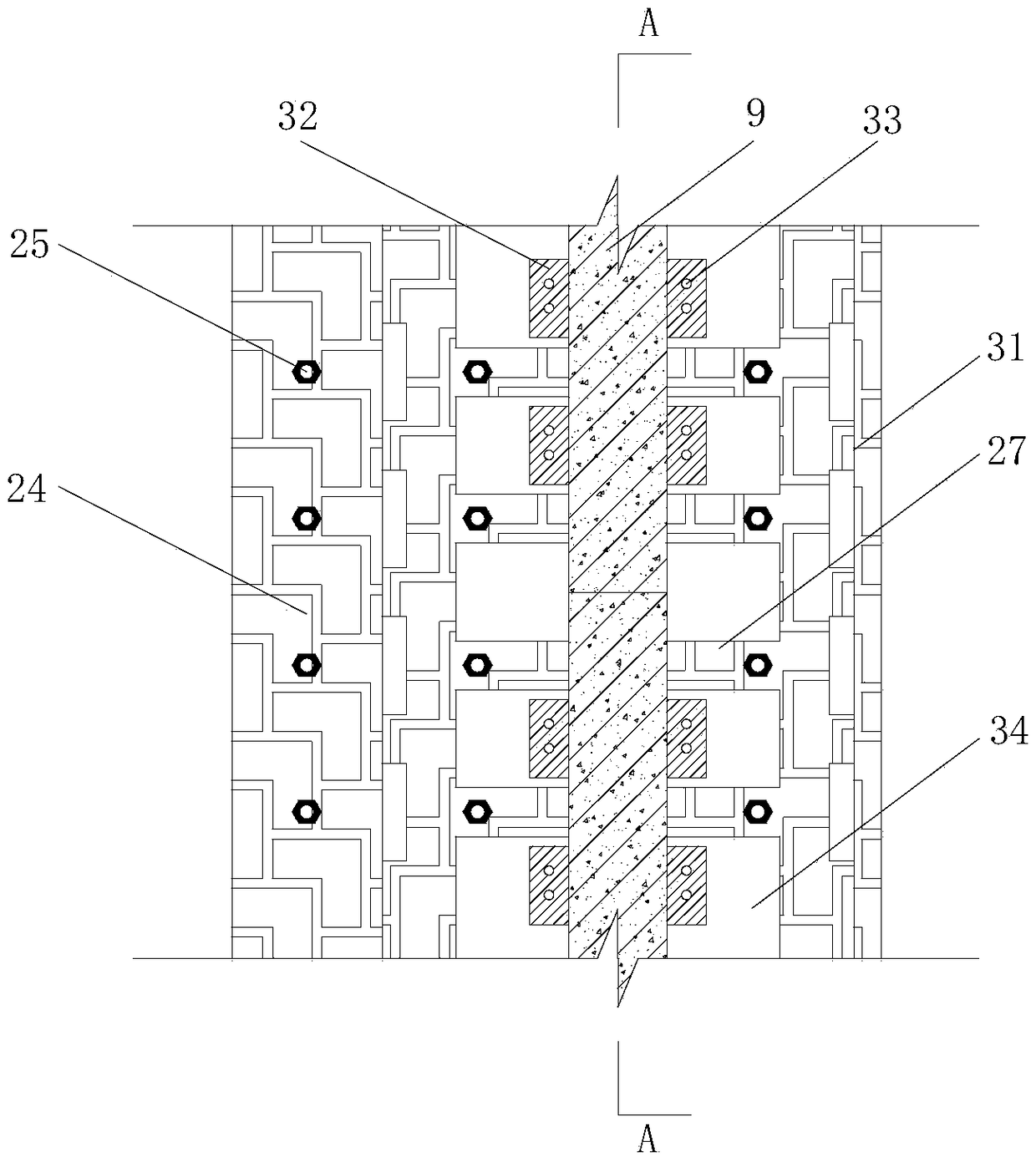

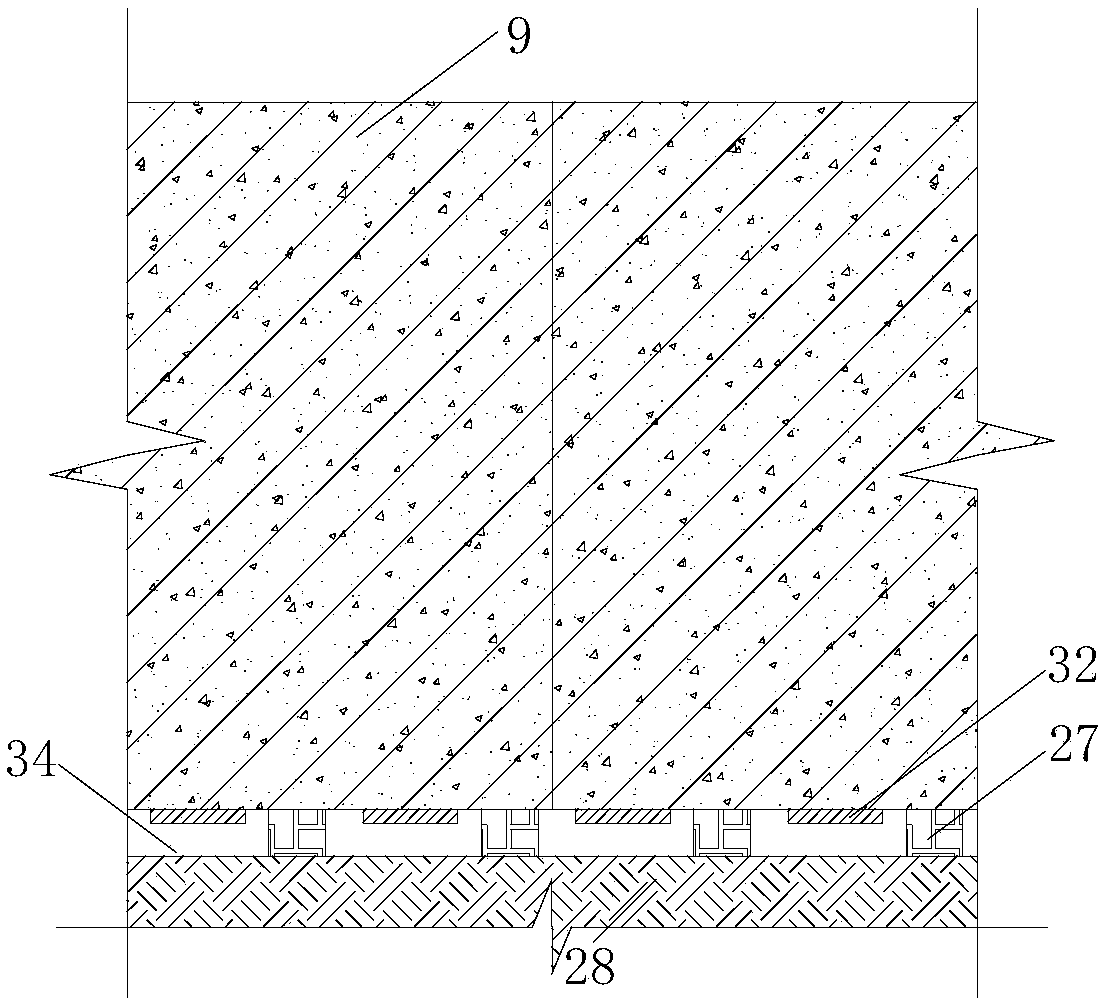

[0036] figure 1 is a schematic diagram of the subgrade widening structure, figure 2 It is the top view of the prefabricated side slab installation before the cast-in-place base slab construction, image 3 yes figure 2 Middle A-A sectional view. Referring to the subgrade widening structure shown in the accompanying drawings, it is mainly composed of prefabricated side slabs, prefabricated assembled side slabs 9, cast-in-place concrete bottom slabs 23, air-filled concrete backfill layers 16, and the like.

[0037] The slope at the interface between the original subgrade and the new subgrade is set in a step shape, and the prefabricated side panels are set on both sides of the cast-in-place concrete bottom slab groove 34, and are fixed by the side panel soil nails 25, the lower solidified soil layer 28 and the in-situ surface 26; the prefabricated assembly type The side plate 9 is arranged on the side plate rib 27, and the two sides are respectively provided with an oblique ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com