Fabric lampshade and preparation method thereof

A lampshade and fabric shade technology, applied in the field of lampshades, can solve the problems of high cost, complex manufacturing process, single shape, etc., and achieve better light effect and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

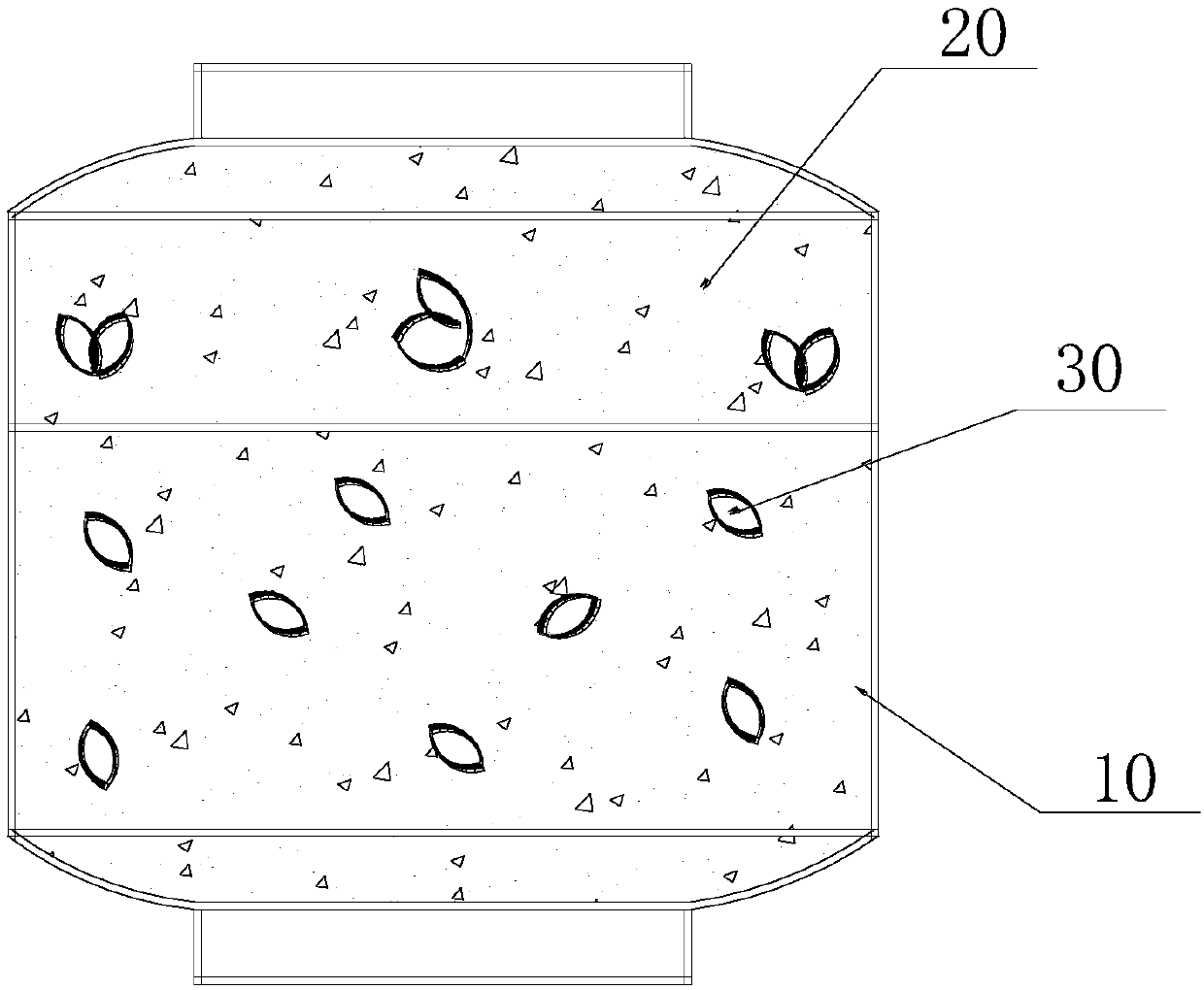

[0022] refer to figure 1 , propose an embodiment of the fabric lampshade of the present invention:

[0023] A fabric lampshade comprises a lampshade frame and a cloth cover 10 wrapped on the lampshade frame. Grit particles 20 are distributed on the cloth cover 10 and coated with a plasticized film coating, and the abrasive particles 20 are fixed on the surface of the cloth cover 10 through the plasticized film coating, and the manufacturing process is simple. The arrangement of the frosted particles 20 makes the lampshade more textured, and the frosted particles 20 can reflect light, and the light effect is better.

[0024] The cloth cover 10 is provided with a plurality of light-transmitting holes 30 , and the shape of the light-transmitting holes 30 can be set as a star shape, a petal shape, or an irregular shape....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com