High-efficiency and anti-blocking flour centrifugal dewatering device

A centrifugal dehydration and anti-clogging technology, applied in filtration separation, separation methods, moving filter element filters, etc., can solve the problems of waste, clogging of sieve holes, and reduce the centrifugal dehydration efficiency of inner flour, and achieve the effect of improving dehydration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

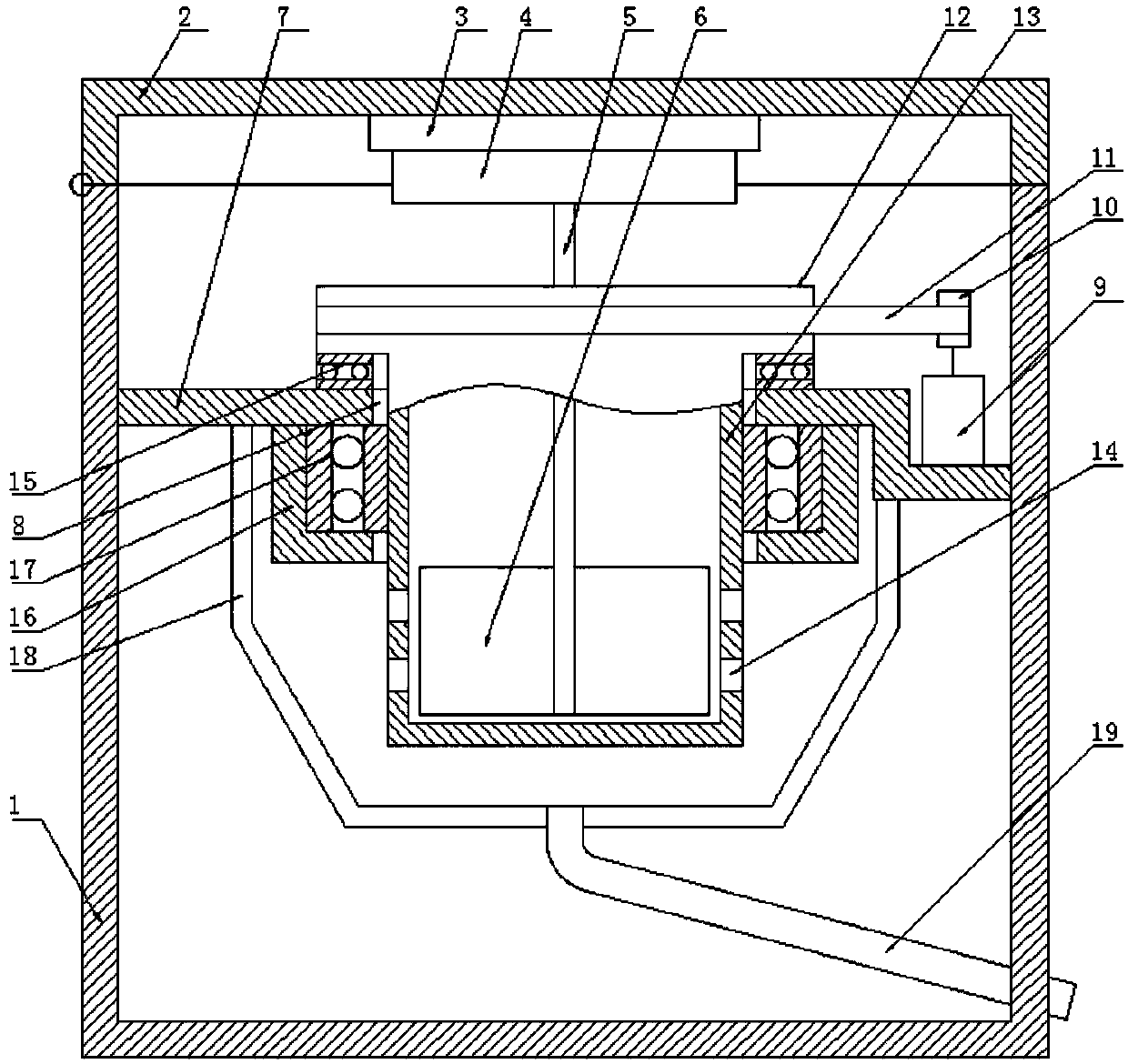

[0009] Example 1, see figure 1 , a high-efficiency anti-clogging flour centrifugal dehydration device, including a body 1, an upper cover 2, a magnet block 3, an iron block 4, a connecting rod 5, a scraper 6, a support plate 7, a through hole 8, a motor 9, and a pulley 10. Transmission belt 11, transmission ring 12, centrifugal cylinder 13, sieve hole 14, thrust ball bearing 15; wherein: the top of the body 1 is equipped with an upper cover 2 through a rotating hinge, and the inner wall of the top of the upper cover 2 is fixed with a magnet block 3 through bolts, The iron block 4 is adsorbed under the magnet block 3, and the scraper sheet 6 is connected to the bottom of the iron block 4 through the connecting rod 5. The scraper sheet 6 can extend into the bottom of the centrifugal cylinder 13, and the support plate 7 is installed in the middle of the body 1. The support plate 7 There is a through hole 8 in the middle, a motor 9 is installed on the edge, and a pulley 10 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com