Beaker capable of achieving mobile stirring

A stirring rod and cup bottom technology, applied in the field of practical room equipment, to shorten the heating time, reduce heat loss, and save alcohol energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

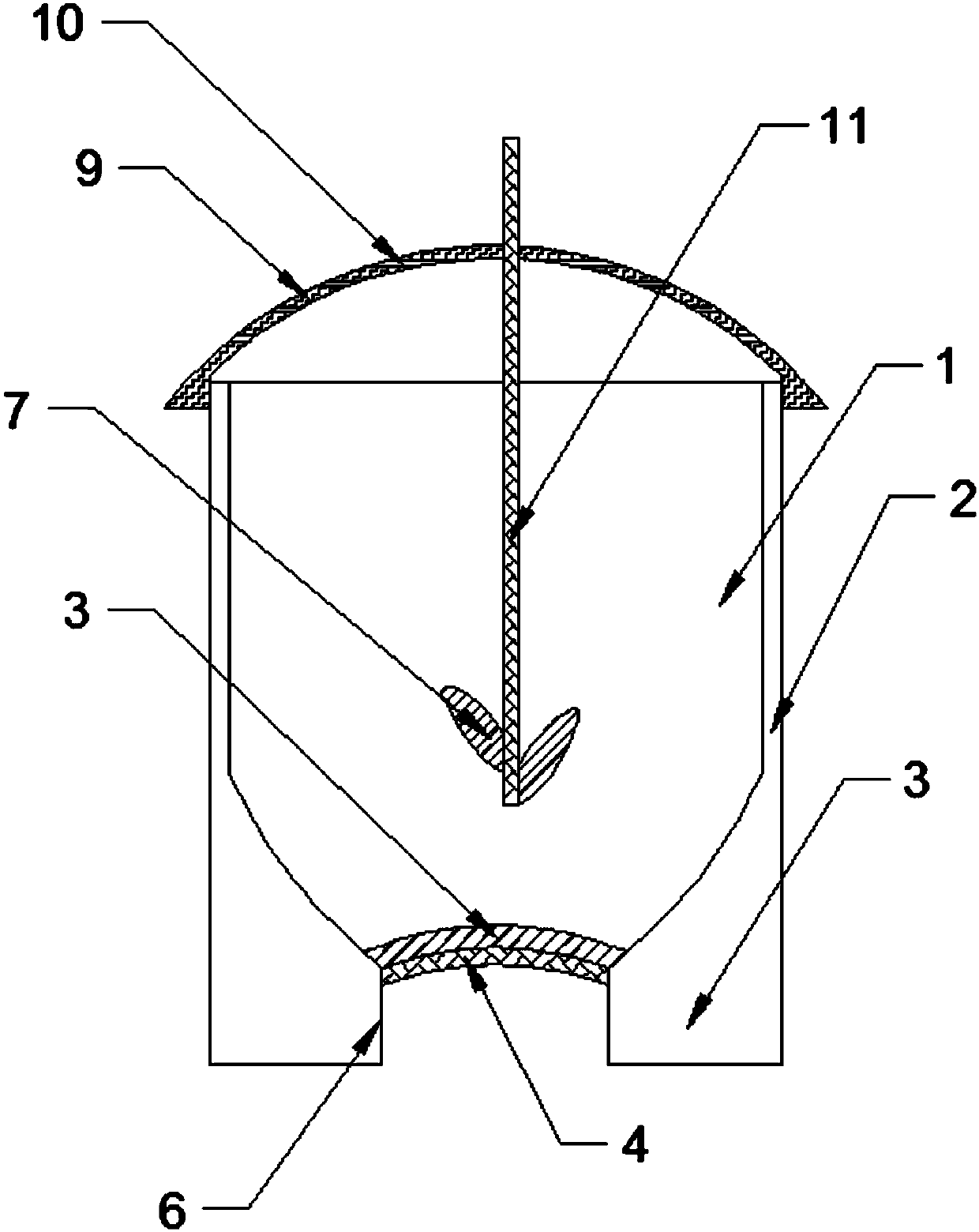

[0028] The technical solution of this embodiment is: a beaker capable of moving and stirring, including a beaker body 1, the side wall of the beaker body 1 is a first vacuum cavity 2, and the bottom of the beaker body 1 protrudes into the beaker body 1 to form an arc shaped cup bottom 3, the edge of the curved cup bottom 3 is integrated with the side wall of the beaker body 1, and the side wall of the beaker body 1 is arranged tangentially with the upper edge of the curved cup bottom 3;

[0029] The bottom of the beaker body 1 is provided with an annular seat 5, the inner diameter of the annular seat 5 is equal to the length of the arc-shaped cup bottom 3 in the horizontal direction, and a carbon black filter screen 4 is arranged in the ring of the annular seat 5, and the carbon black filter screen 4 is detachable connected to the inner wall of the ring seat 5;

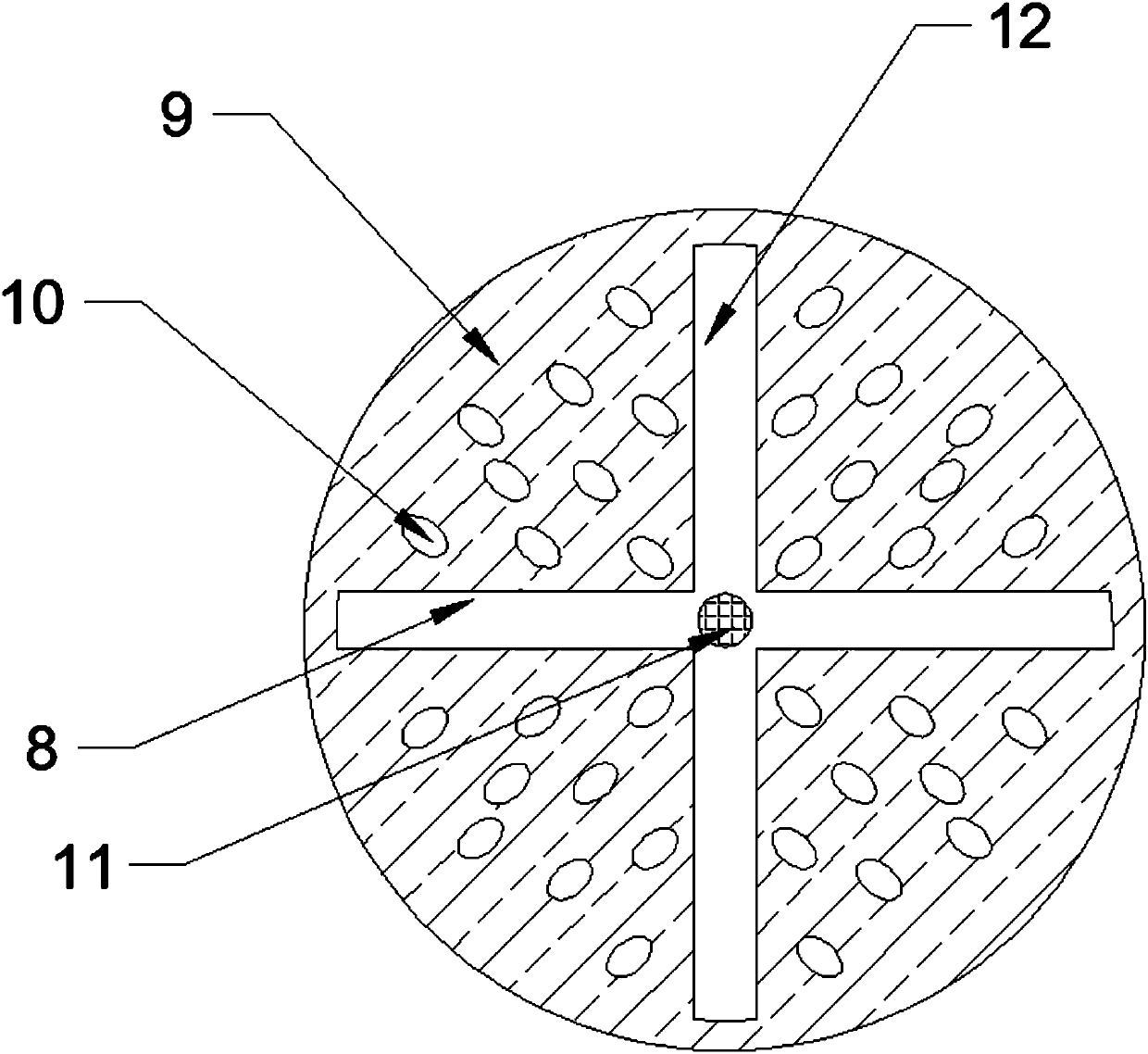

[0030] The upper end of the beaker body 1 is threadedly connected with an arc-shaped cover body 9, and a cylindrica...

Embodiment 2

[0038] Based on the first embodiment, the technical solution of this embodiment is: the carbon black filter 4 is closely attached to the bottom of the arc-shaped cup bottom 3 .

[0039] Such as figure 1 As shown, the carbon black filter screen 4 is closely attached to the bottom of the curved cup bottom 3, so that the filtered flame can directly heat the curved cup bottom 3 after passing through the carbon black filter screen 4.

Embodiment 3

[0041] Based on the first embodiment, the technical solution of this embodiment is: a second vacuum chamber 6 is formed between the inner ring and the outer ring of the annular seat 5 .

[0042] Such as figure 1 As shown, the second vacuum cavity 6 is used in the process of the flame propagating to the arc-shaped cup bottom 3, heat energy is dissipated through the annular seat 5, and the heat of the arc-shaped cup bottom 3 is prevented from being transferred to the outside of the beaker body 1 and dissipated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com