Construction waste recycled aggregate vibration air separation equipment

A technology of recycled aggregates and winnowing equipment, applied in the direction of solid separation, separating solids from solids with airflow, chemical instruments and methods, etc., can solve the problem of limited utilization rate of construction waste resources and the separation accuracy of recycled aggregates The range of product applications cannot effectively sort broken brick aggregates and near-density impurities, and the problem of sorting recycled aggregate mixtures is not fundamentally solved, so as to alleviate the damage to the ecological environment of agriculture and forestry, achieve superior performance, and improve resource utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

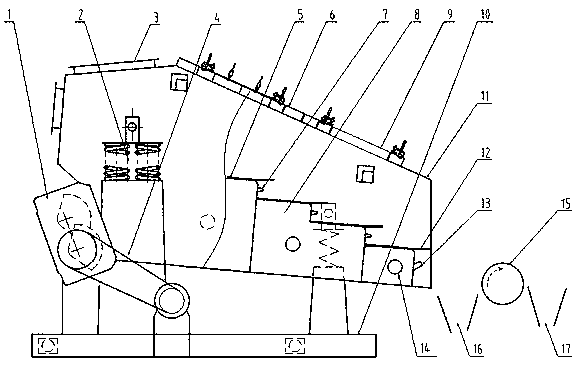

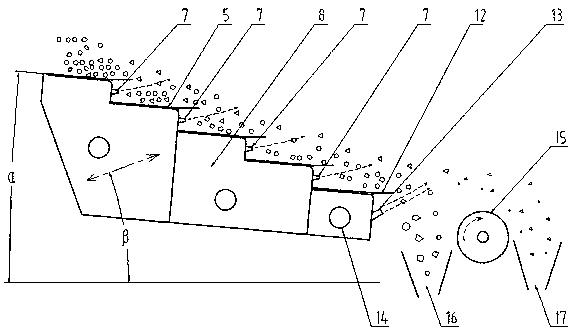

[0010] The embodiments of the present invention will be described below in conjunction with the drawings: including a supporting device, a vibration damping device, a vibration device, a mainframe box and a sorting device. The mainframe box 11 is installed on the support device 10 through the vibration damping device 2, and the vibration device 1 is installed on the mainframe box 11. At the lower part of the main box body 11, a wind box 8 is provided. The upper surface of the wind box 8 is in a stepped shape from the feed end to the discharge end of the main box body 11, and the inclination angle α of the stepped surface of the wind box is 5°. Each step above the wind box 8 is equipped with a wear plate 5, and an adjusting plate 12 is connected at the edge of the wear plate 5, and the width of the adjusting plate 12 exceeds the edge of the step. On the wall of the wind box below the adjusting plate 12, an exhaust air port 7 is installed. The air outlet provided on the last ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com