Detection method for particle size of polymer polyol

A detection method, polyol technology, applied in the direction of particle size analysis, measuring device, particle and sedimentation analysis, etc., can solve the problems of unsuitable graft polymer polyol detection results, errors, etc., to achieve loss prevention, high precision, particle size accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A detection method of polymer polyol particle size, the steps are as follows:

[0025] (1) Select a 150-mesh stainless steel filter, the size of which is length × width × height: 5cm × 5cm × 2cm; weigh 100 grams of polymer polyol sample, and divide it into two parts (accurate to 0.1mg).

[0026] (2) Measure 100ml of isopropanol solvent, dilute one of the polymer polyol samples with isopropanol solvent, filter the diluted sample with a stainless steel filter, and remove the diluted sample by pouring under natural conditions A good sample allows liquids and particles smaller than a certain mesh to pass through.

[0027] (3) Dry the filtered particles together with the filter screen and place them in a vacuum drying oven at 70°C to 100°C for 10 minutes. After cooling the sample and the filter to room temperature, weigh and calculate the content of the particle size of the sample.

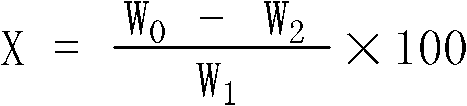

[0028] Calculation formula: X = W ...

Embodiment 2

[0037] Except following difference, other is with embodiment 1.

[0038] (1) Weigh 60 grams of polymer polyol sample and divide it into two parts (accurate to 0.1 mg).

[0039] (2) Measure 150ml of ethanol solvent.

[0040] (3) The temperature of the vacuum drying oven is 70-90°C, and the drying time is 5 minutes.

Embodiment 3

[0042] Except following difference, other is with embodiment 1.

[0043] (1) Weigh 80 grams of polymer polyol sample and divide it into two parts (accurate to 0.1 mg).

[0044] (2) Measure 200ml of acetone solvent.

[0045] (3) The temperature of the vacuum drying oven is 80-100°C, and the drying time is 15 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com