Automatic discharging device of material pulling frame

A technology of automatic unloading device and material frame, applied in vibrating conveyors, transportation and packaging, conveyors, etc., to achieve the effects of ensuring smooth operation, improving production efficiency, and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

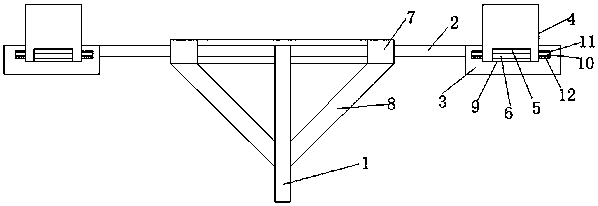

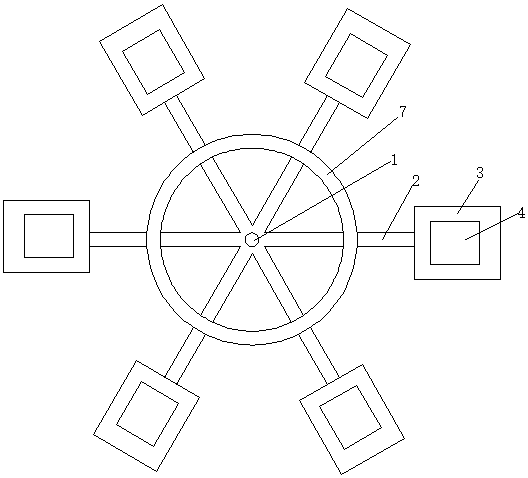

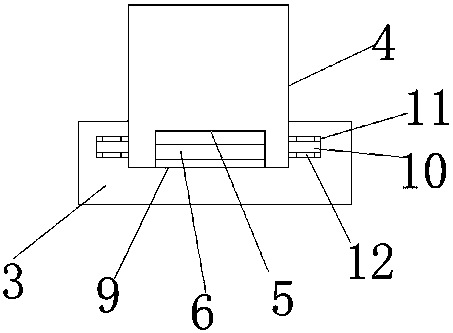

[0015] As shown in the figure, the automatic unloading device for the pulling frame of the present invention includes a rotating shaft 1, and a plurality of support rods 2 that diverge are evenly spaced around the upper end of the rotating shaft 1, and one end of each supporting rod 2 is rotatably connected to the rotating shaft 1. The other end of the support rod 2 is provided with a support base 3, a pull frame 4 is installed above the support base 3, a groove 5 is set at the bottom of the pull frame 4, and a vibration mechanism 6 is installed in the groove 5.

[0016] Further, a circular auxiliary support frame 7 is connected in the middle of a plurality of support rods 2, and an inclined support frame 8 is arranged below the circular auxiliary support frame 7. One end of the inclined support frame 8 is connected to the circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com