Slewing bearing stress distribution monitoring method based on fiber bragg gratings

A fiber grating and slewing bearing technology is applied in the direction of force measurement, measurement force, and measurement device by measuring the change of optical properties of materials when they are stressed, which can solve problems such as inability to accurately judge the safe state, and improve safety and reliability. Reliable, fast and accurate measurements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

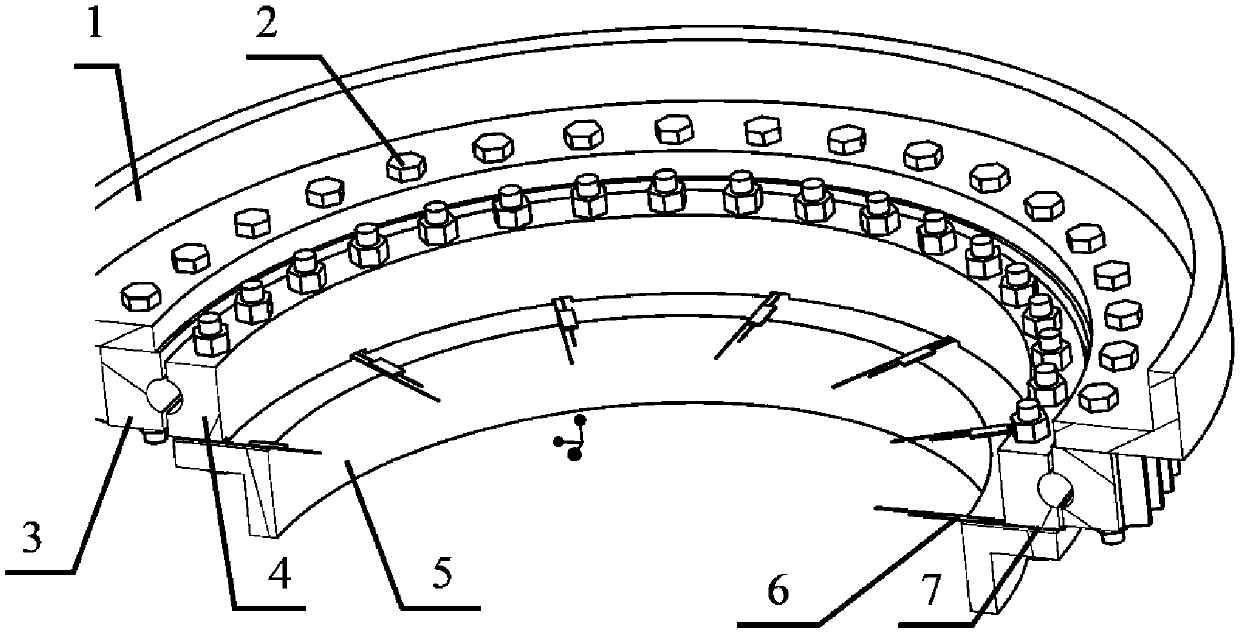

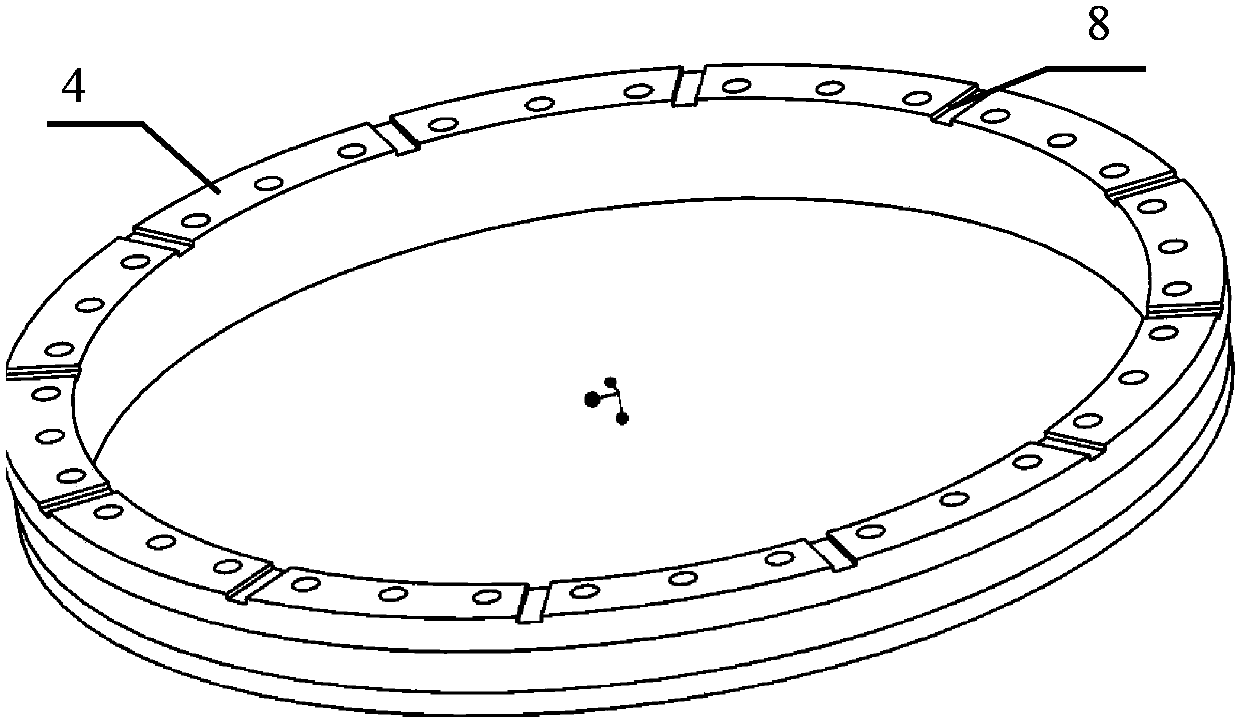

[0031] Such as Figure 1 to Figure 5 , a method for monitoring the stress distribution of a slewing bearing based on an optical fiber grating, characterized in that it comprises the following steps:

[0032] Step (1), uniformly distributed grooves (8) are formed on the end surface of the fixed ring (4) of the slewing bearing. The shape and distribution of the grooves ensure the accuracy of the test without affecting the mechanical structural strength of the slewing bearing;

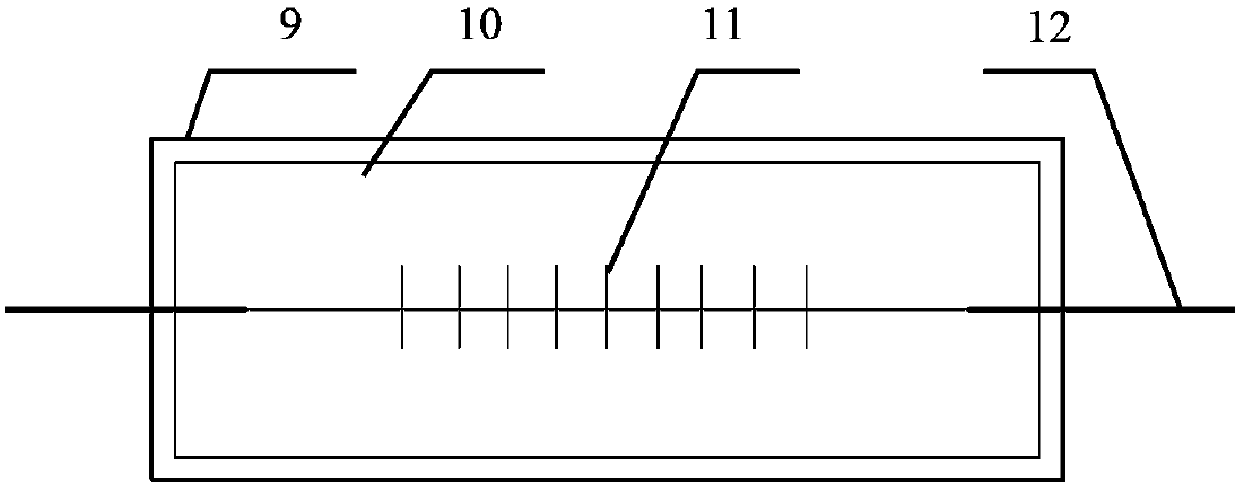

[0033] Step (2), paste the fiber grating strain sensor (7) in the ring groove (8) of the slewing ring with epoxy resin, and install the fiber grating temperature sensor (6) near each fiber grating strain sensor for temperature compensation, and the optical fiber The grating temperature sensor (6) is close to the fiber grating strain sensor (7), without contacting the fixed ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com