Multifunctional friction and wear tester based on pin-on-disk friction pair and test method thereof

A technology of friction and wear test and friction pair, which is applied in the direction of testing wear resistance, measuring devices, and adopting mechanical devices, etc., to achieve the effect of saving test costs and increasing the degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

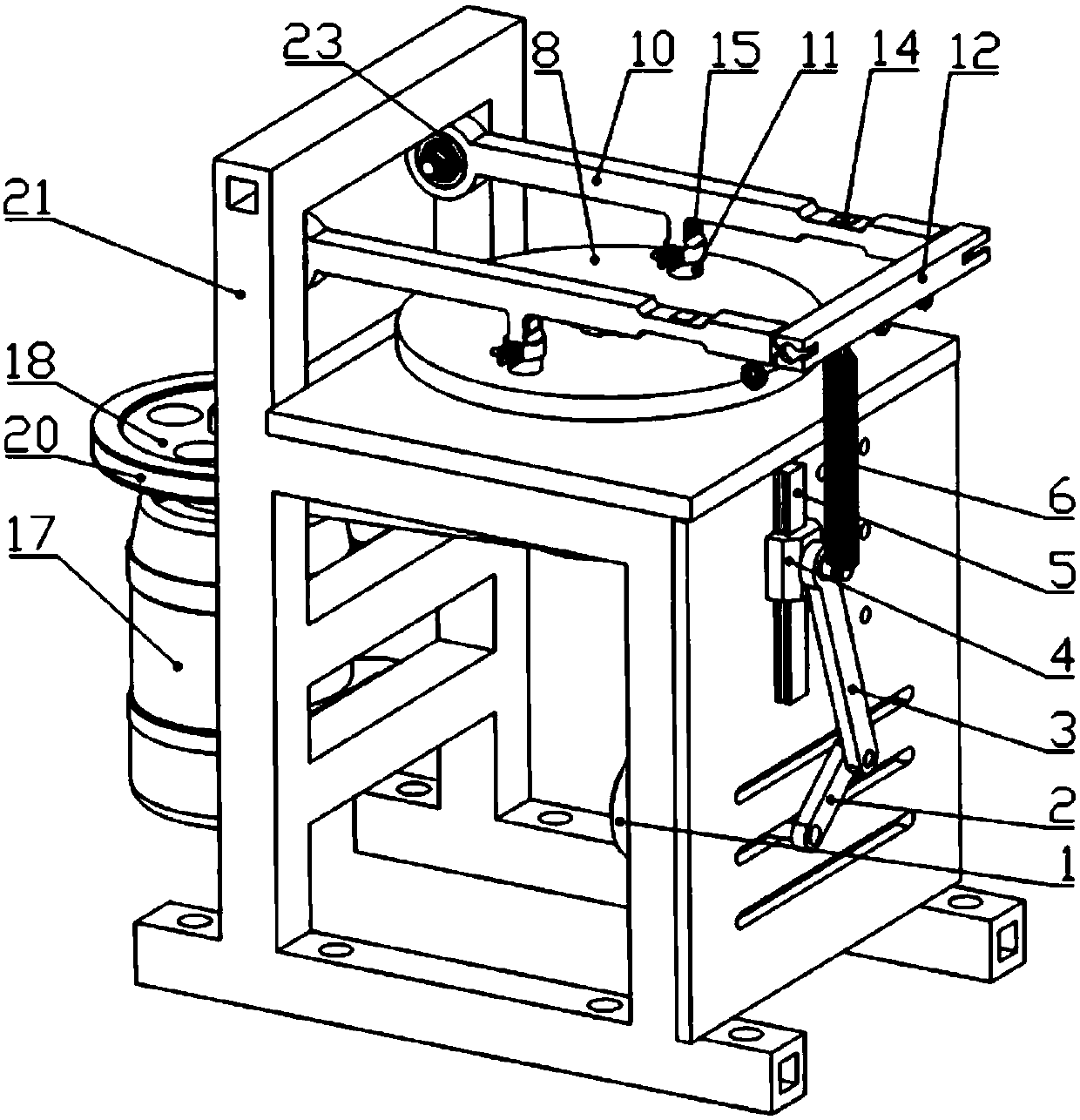

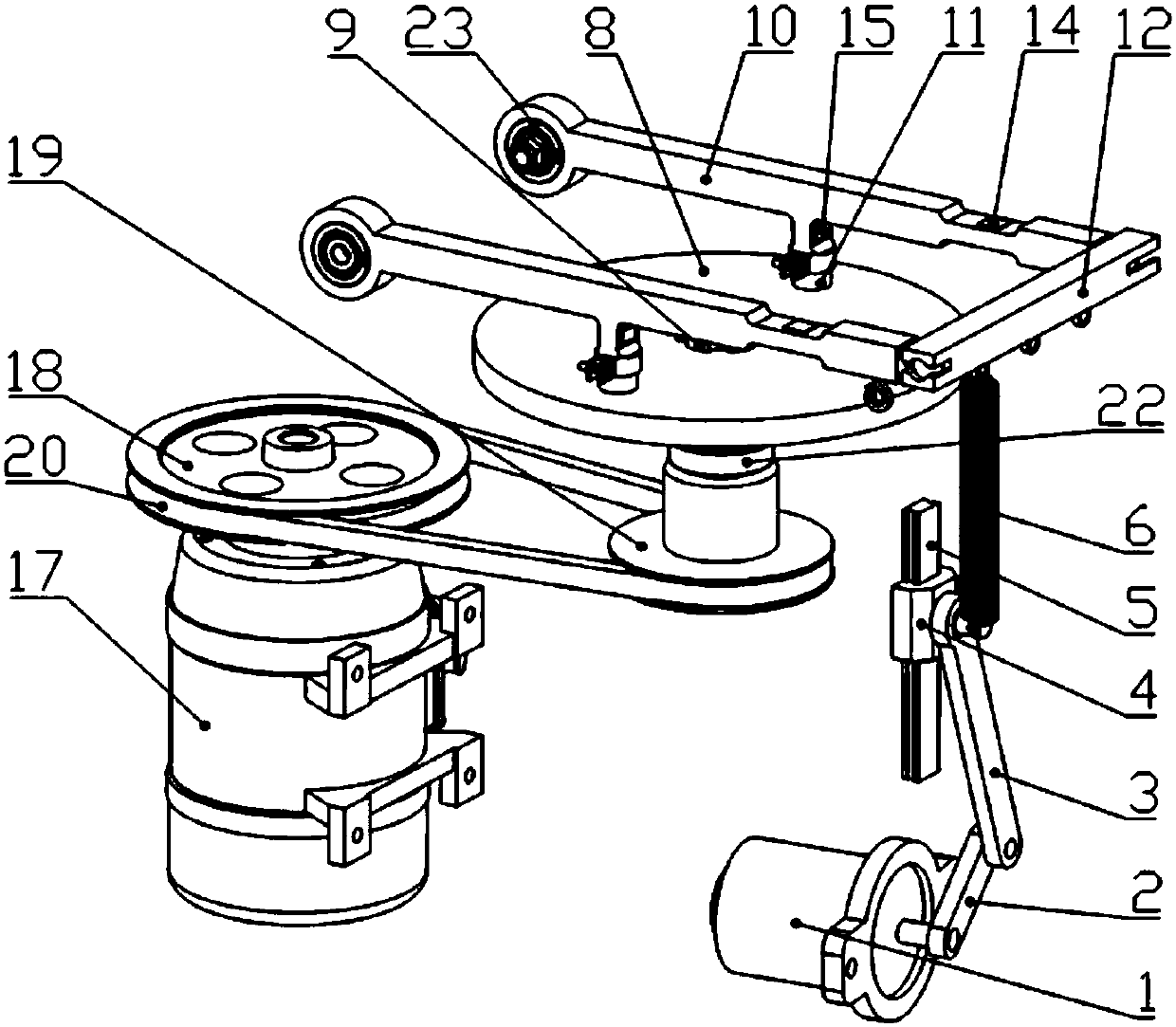

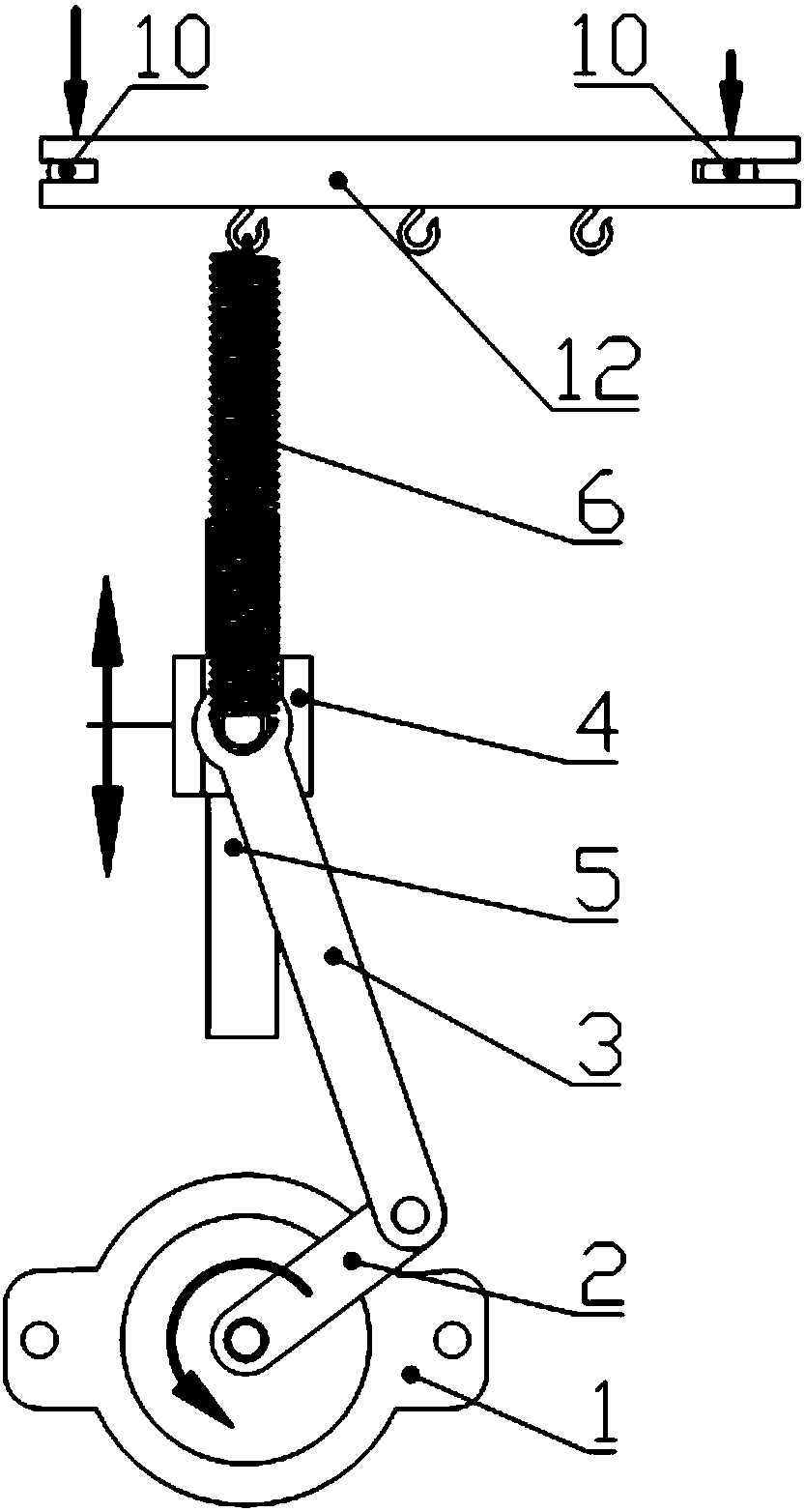

[0047] The invention provides a multi-functional friction and wear testing machine based on a pin-disk friction pair, the loading test machine includes: a drive system, a double-pin-disc friction pair, a cyclic load loading device, a data acquisition analysis and display system, and a mechanical support system. Wherein, the drive system, the cyclic load loading device and the double-pin-disk friction pair are all installed in a mechanical support system, and the mechanical support system is composed of a base support 21 and several fastening connectors such as bolts, and the base support 21, as the base of the entire experimental device, has a highly rigid frame structure to provide mechanical support for each component. The bottom of the base bracket 21 is provided with a fixing device to fix the whole device on the pedestal or the ground iron; the drive system is installed On the rear side of the base support 21 , the pin-disc friction pair is installed above the base suppor...

Embodiment 2

[0063] The invention provides a multi-functional friction and wear testing machine based on a pin-disc friction pair, the loading test machine includes: a drive system, a double-pin-disc friction pair, a constant load loading device, a data acquisition analysis and display system, and a mechanical support system. Wherein, the drive system and the double-pin disc friction pair are all installed in a mechanical support system, the mechanical support system is composed of a base support 21 and several fastening connectors such as bolts, and the base support 21 is used as the entire experimental device The base body has a highly rigid frame structure to provide mechanical support for each component. The bottom of the base bracket 21 is provided with a fixing device to fix the entire device on the pedestal or level iron; the drive system is installed on the base bracket 21 The rear side of the pin-on-disk friction pair is installed above the base bracket 21.

[0064]The "drive sys...

Embodiment 3

[0071] The invention provides a multifunctional friction and wear testing machine based on a pin-disk friction pair, the loading test machine includes: a drive system, a single-pin-disk friction pair, a cyclic load loading device, a data acquisition analysis and display system, and a mechanical support system. Wherein, the drive system, the cyclic load loading device and the double-pin-disk friction pair are all installed in a mechanical support system, and the mechanical support system is composed of a base support 21 and several fastening connectors such as bolts, and the base support 21, as the base of the entire experimental device, has a highly rigid frame structure to provide mechanical support for each component. The bottom of the base bracket 21 is provided with a fixing device to fix the whole device on the pedestal or the ground iron; the drive system is installed On the rear side of the base support 21 , the pin-disc friction pair is installed above the base support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com