Color laser copier self-cleaning working method

A working method, color laser technology, applied in the fields of optics, electrography, instruments, etc., can solve the problems of affecting the effect of copying, reducing work efficiency, and forming a clear shadow, etc., to improve the effect of copying and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below by means of specific embodiments:

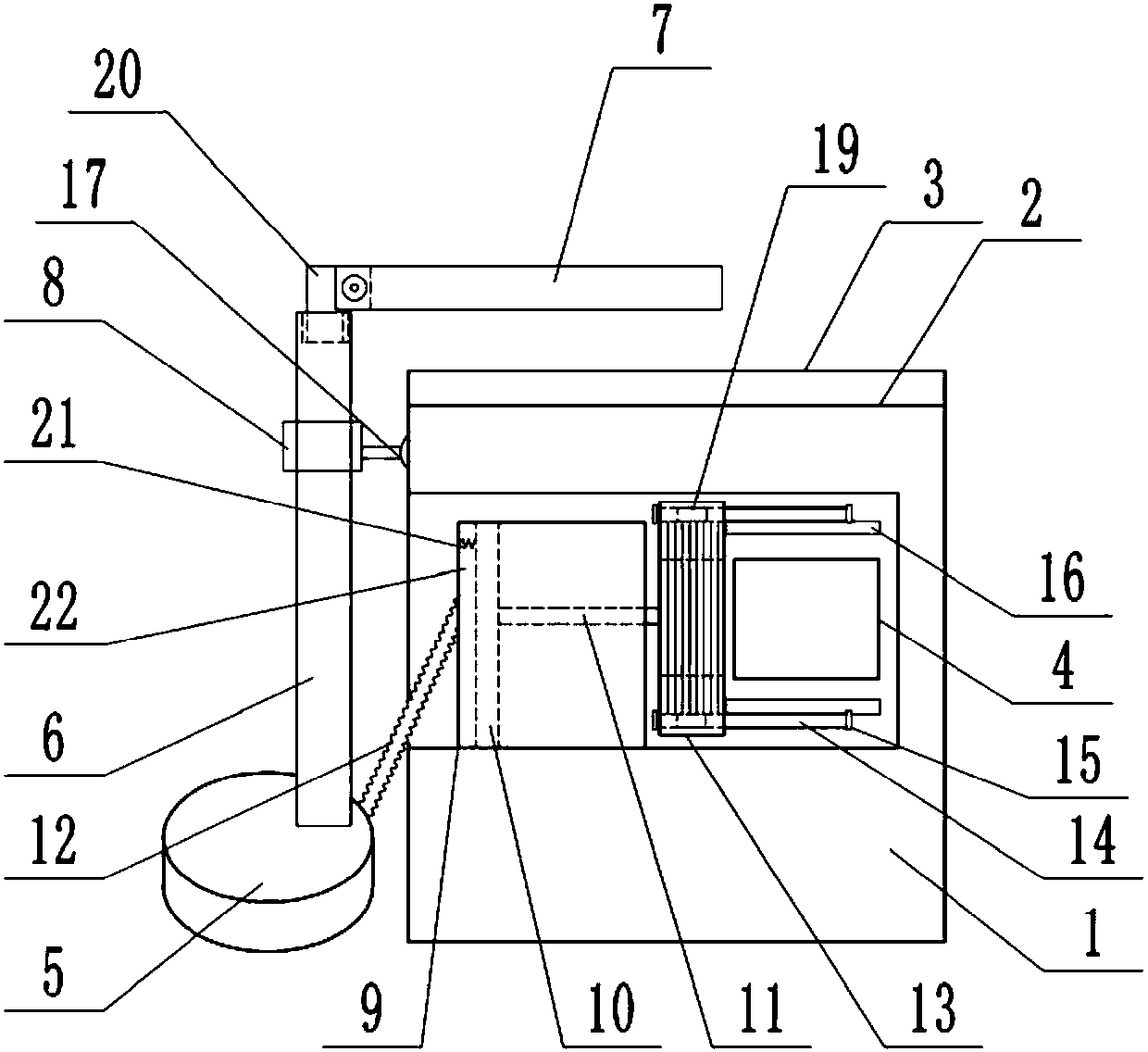

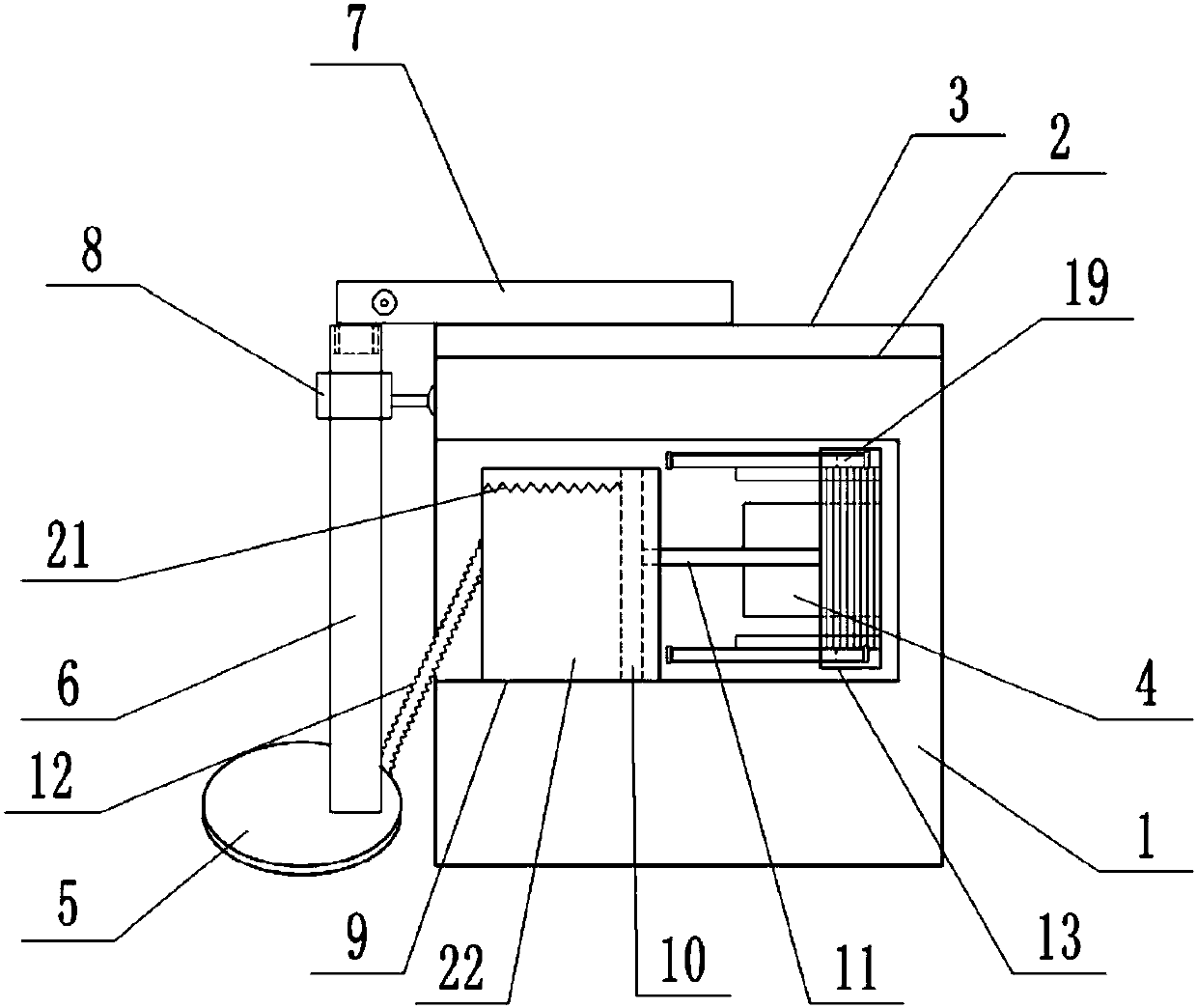

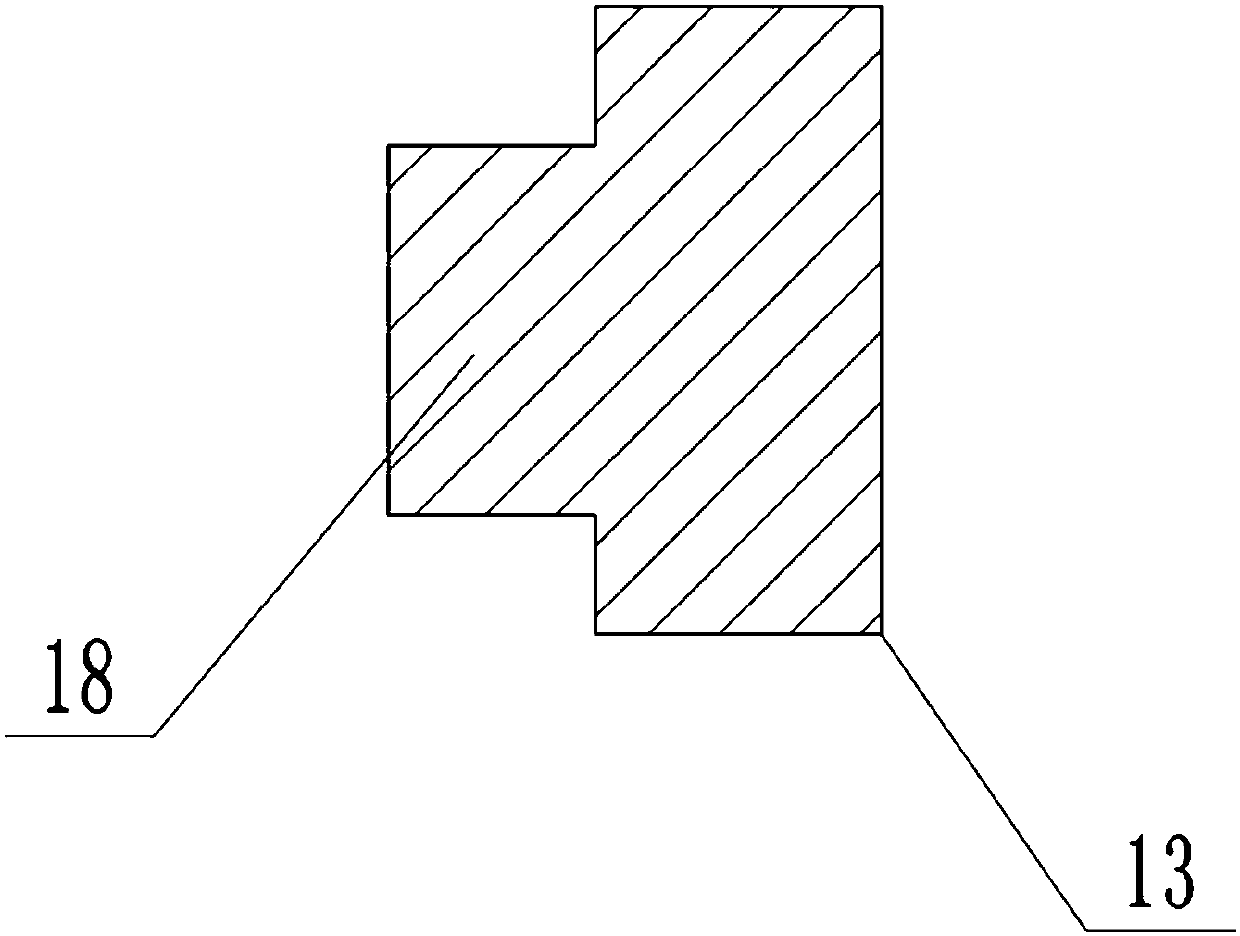

[0028] The reference signs in the accompanying drawings of the description include: copier body 1, platen 2, cover plate 3, paper outlet 4, air bag 5, pressing rod 6, pressing plate 7, guide rod 8, cylinder body 9, piston 10, pushing Rod 11, bellows 12, cleaning block 13, slide rail 14, limit block 15, fur sticker 16, suction cup 17, protrusion 18, pulley 19, movable column 20, return spring 21, closed space 22.

[0029] like Figure 1 to Figure 3 As shown, the embodiment of the present invention uses a color laser copier, including a copier body 1, a platen 2 and a cover plate 3 hinged with the copier body 1; Overcoat has guide bar 8 that can be fixed along the vertical direction, and guide bar 8 is provided with the sucker 17 that can be fixed on the wall or copier body 1, and the upper end of pressing bar 6 is provided with groove, is provided with movable column 20 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com