A positioning insulation packaging structure of a thermistor

A technology of thermistor and packaging structure, which is applied in the field of temperature sensing, can solve the problems of high cost, insufficient insulation, and difficult processing of metal probes, and achieve the effect of improving tensile strength and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

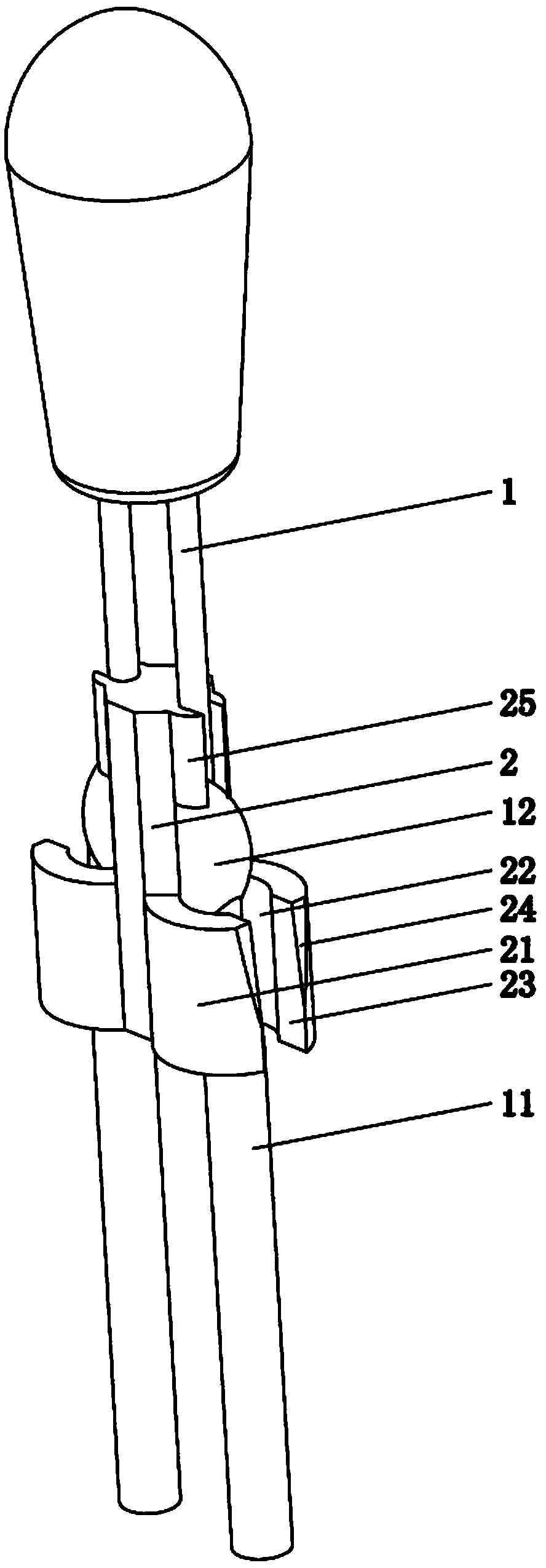

[0017] Such as figure 1 As shown, a thermistor positioning insulation packaging structure described in the present invention includes two pins 1 and lead wires 11 of the thermistor, the two pins 1 are drawn from the same end of the thermistor, and the lead wire 11 The core of the wire is welded on the pin 1 to form a welding spot 12; an insulating strip 2 is pierced between the two welding spots 12; the lower end of the insulating strip 2 penetrates between the two lead wires 11, and the insulating strip 2 Both sides of the lower end are provided with wire clamps 21, and the two wire clamps 21 are respectively clamped on the rubber of the lead wire 11 on the corresponding side; the insulating strip 2 and the two wire clamps 21 form an integrated structure of an inverted "T", and the two The outer end face of the wire clamp 21 is an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com