Power mosfet device with low characteristic on-resistance and method of manufacturing the same

A technology of on-resistance and devices, which is applied in the field of power semiconductor devices, can solve problems such as increasing manufacturing costs, reducing product reliability, and hidden dangers of reliability, so as to reduce manufacturing difficulty and cost, increase gate oxide withstand voltage quality, and reduce drive voltage. The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described below in conjunction with specific drawings and embodiments.

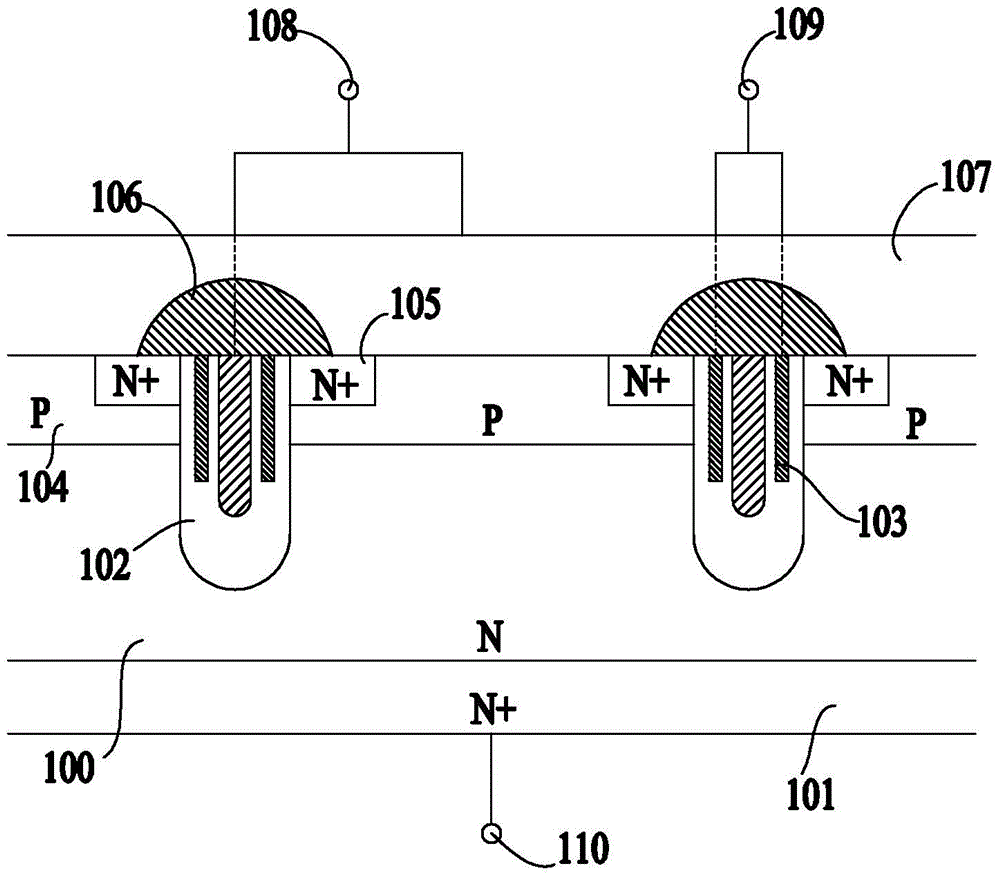

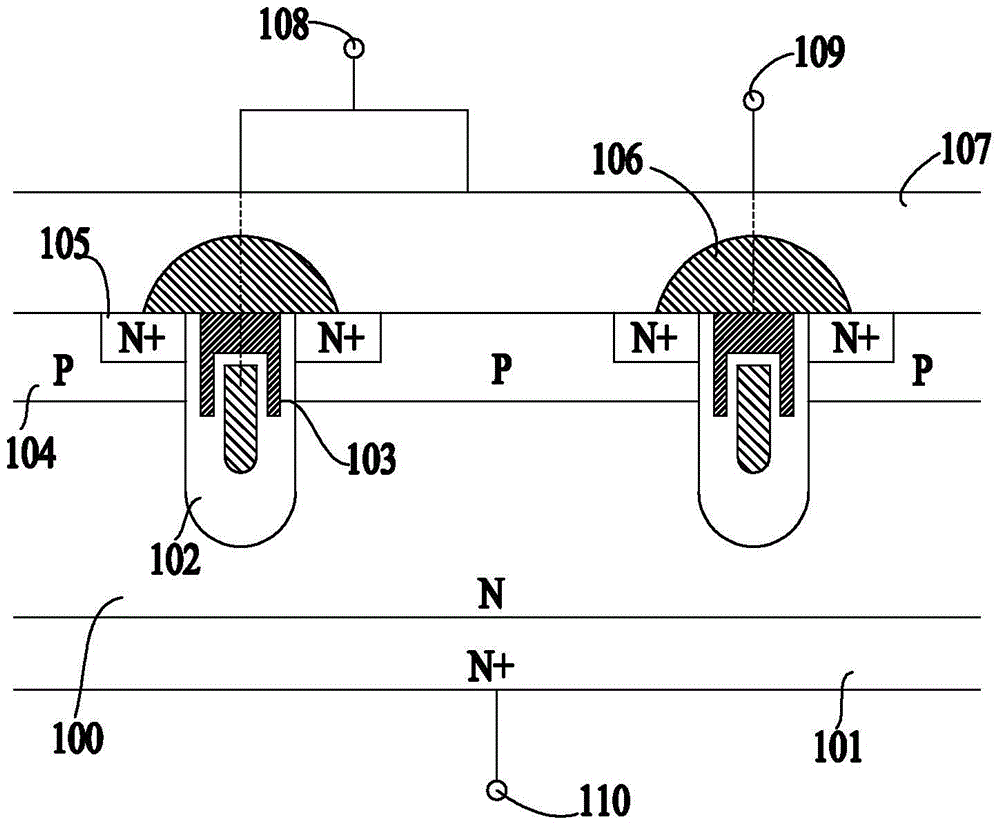

[0070] Such as figure 1 Shown: is the implementation structure diagram of the existing trench power MOSFET device with low characteristic on-resistance, in which, on the cross-section of the power MOSFET device, the element area of the power MOSFET device adopts a trench structure, and the cell trench is located in In the N-type drift region 100 , the depth of the cell trench is smaller than the thickness of the N-type drift region 100 , and the N-type drift region 100 is adjacent to the N+ substrate region 101 . A P-type well region 104 is provided in the upper part of the N-type drift region 100 , and the P-type well region 104 runs through the N-type drift region 100 . A trench insulating oxide layer 102 and a trench polysilicon 103 are arranged in the cell trench, and an N+ cell implantation region 105 is arranged outside the notch of the cell trench, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com