A high-voltage cable trench cable laying auxiliary probe installed with thread structure

A cable laying and cable trench technology, applied in cable laying equipment, cable installation, cable installation devices, etc., can solve the problems of cumbersome cable trench covers, dark high-voltage cable trenches, time-consuming and labor-intensive, etc. The number of times, the convenience of laying, and the effect of reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

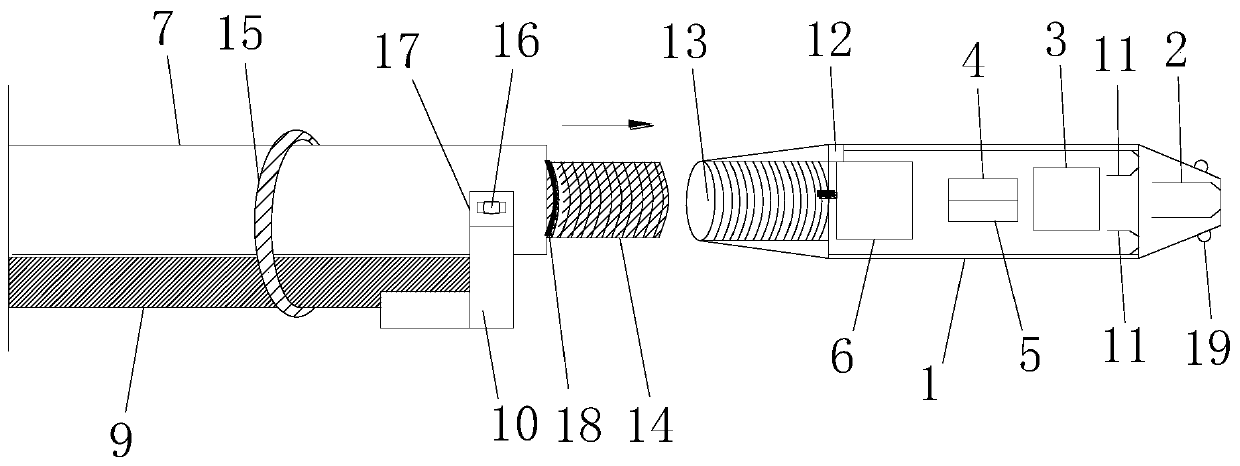

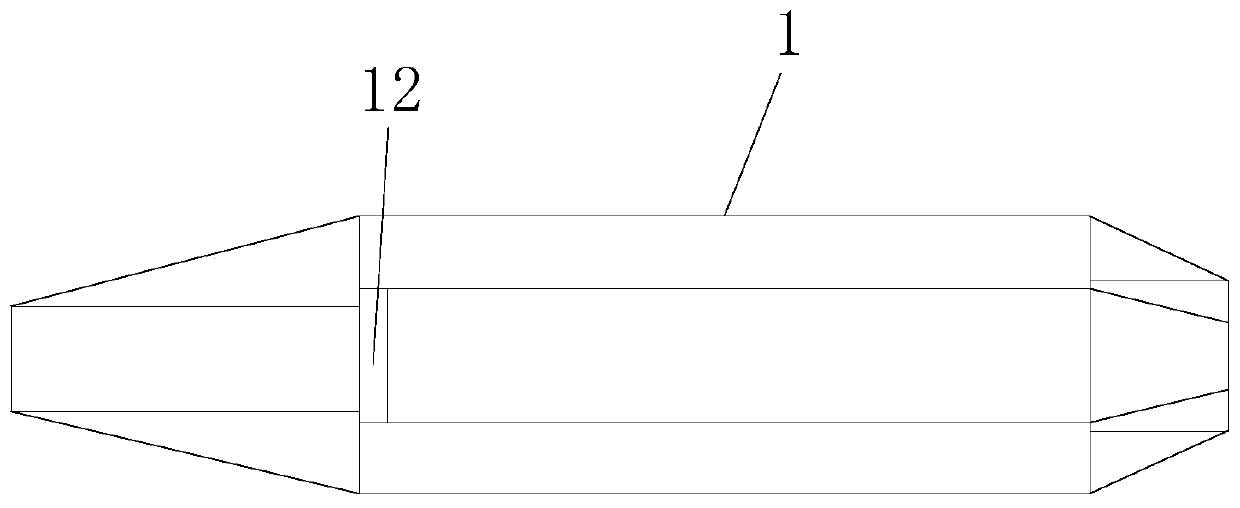

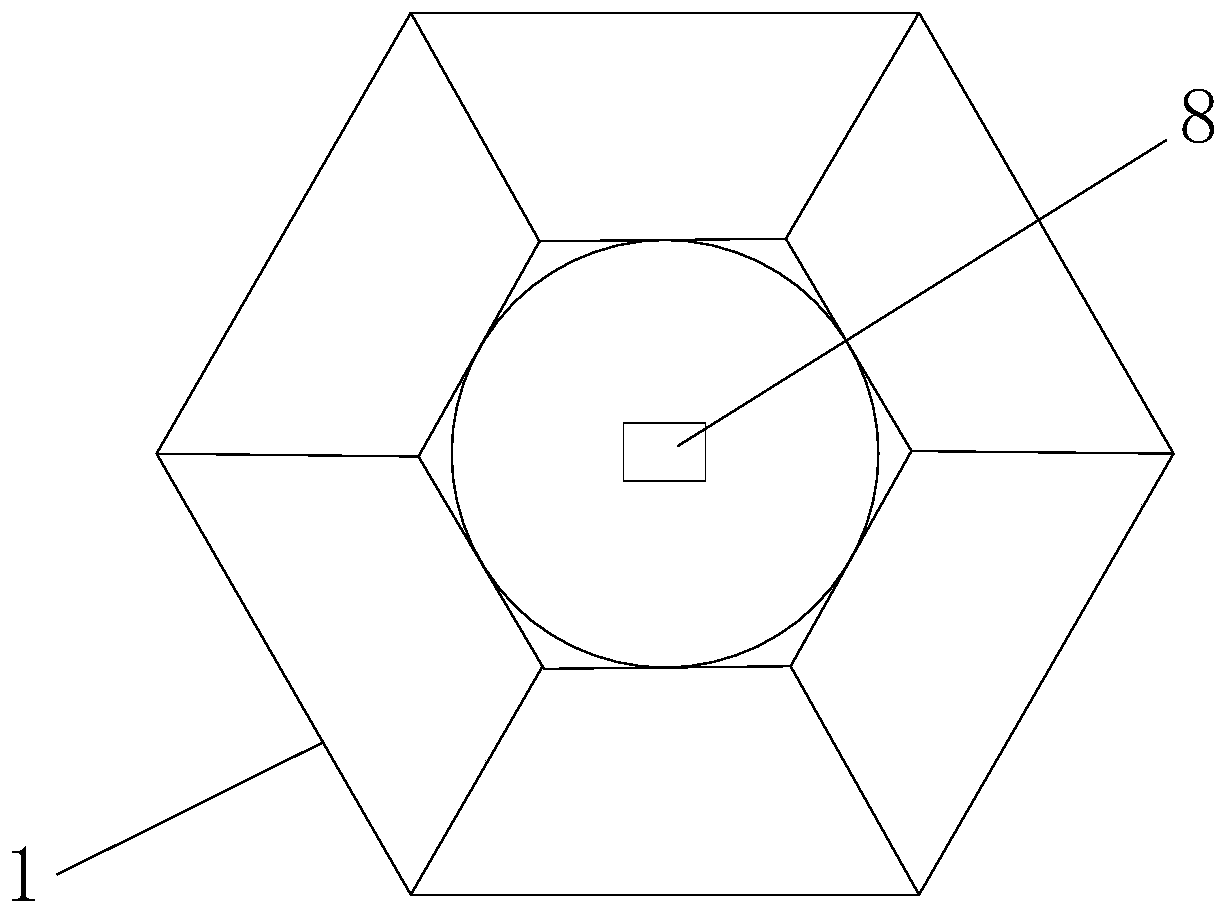

[0033] Such as Figure 1 to Figure 4 As shown, it is a high-voltage cable trench cable laying auxiliary probe installed with a threaded structure of the present invention, including a probe body 1, an optical lens 2 is arranged in the head of the probe body 1, and a CCD camera is arranged in the middle part of the probe body 1 3. The CCD camera 3 is connected to the optical lens 2. The middle part of the probe body 1 is provided with a wireless receiver 4 and a hotspot generator 5. The wireless receiver 4 and the hotspot generator 5 are connected to an external platform for information exchange. The middle part of the probe body 1 The position is provided with an LED infrared lamp 11, and the design of the LED infrared lamp 11 can be convenient for actual lighting, so that the dark cable trench can be visualized, and it is convenient for the shooting and use of the CCD camera 3. The middle part of the probe body 1 is provided with a lithium battery 6 , The middle part of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com