Rigid polyurethane foam comprising polyester polyether polyol

A polyether polyol, polyurethane foam technology, applied in the field of rigid polyurethane foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

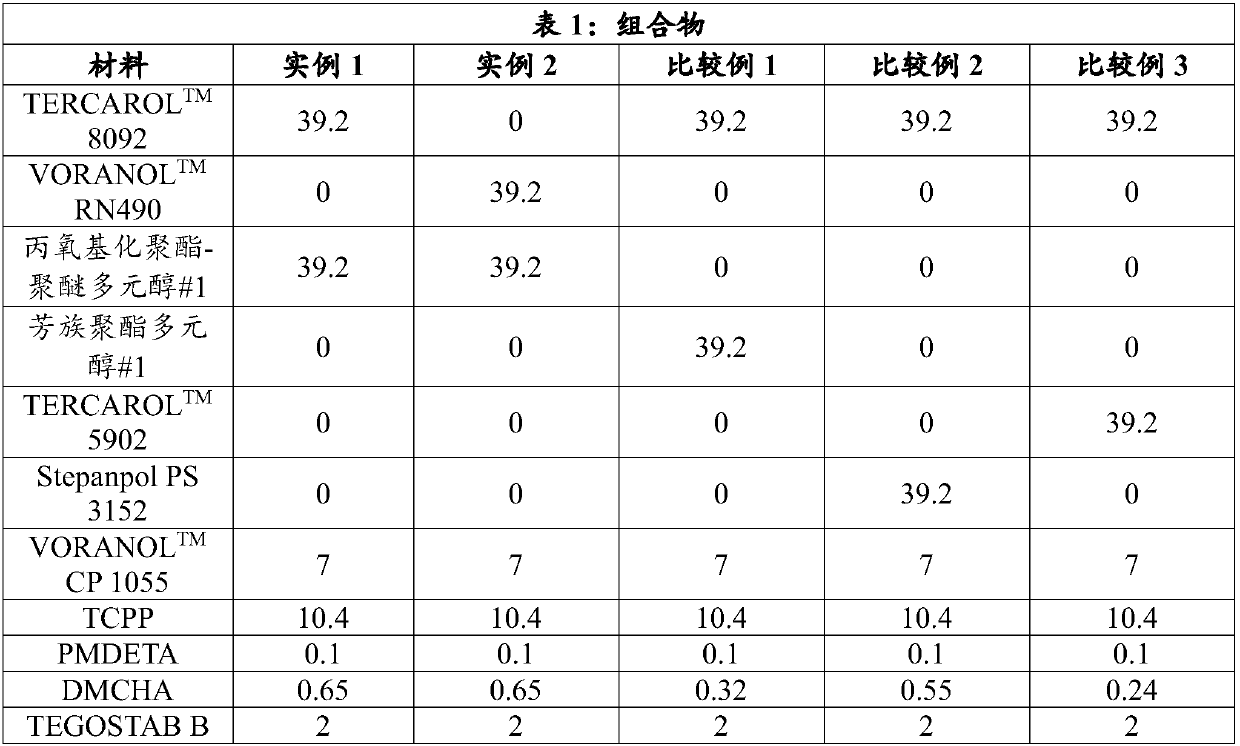

[0042] The following examples are provided to illustrate various embodiments, but are not intended to limit the scope of the claims. All parts and percentages are by weight unless otherwise indicated.

[0043] The raw materials used in the examples are described as follows:

[0044] TERCAROL TM 8092 is a sorbitol-initiated polyether polyol available from The Dow Chemical Company (Midland, Mich.) having a hydroxyl value of 460 mg KOH / g and an average functionality of 5;

[0045] VORANOL TM RN490 is a reaction mass of sucrose propoxylation and glycerol propoxylation available from The Dow Chemical Company (Midland, Mich.), having a hydroxyl value of 490 mg KOH / g and an average functionality of 4.3;

[0046] Aromatic polyester polyol #1 is an aromatic polyester polyol from terephthalic acid, polyethylene glycol, and glycerin available from The Dow Chemical Company (Midland, Mich.) with 315 mg KOH / g Hydroxyl value and average functionality of 2.4;

[0047] TERCAROL TM 590...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap