Swine feeding equipment

An equipment and technology for live pigs, applied in the field of breeding, can solve the problems of labor cost, feed waste, pollution of feedlots, etc., and achieve the effect of preventing failures and inability to mix materials, improving speed and efficiency, and mixing evenly and adequately.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

[0019] The present invention will be further described below through specific examples, but not in order to limit the present invention, all within the spirit and principle of the present invention, any modification, equivalent replacement, improvement etc. all should be included within the scope of protection of the present invention .

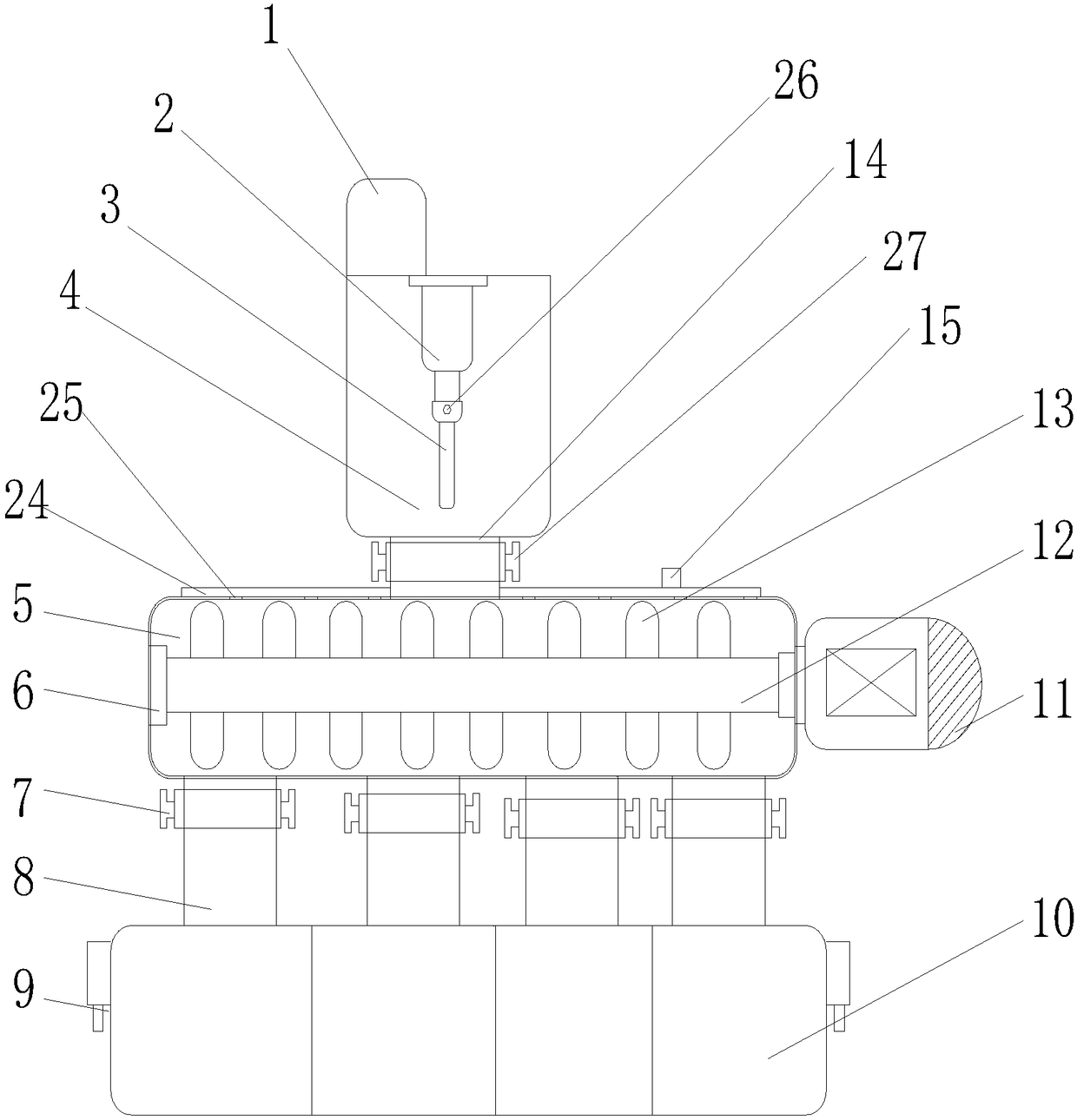

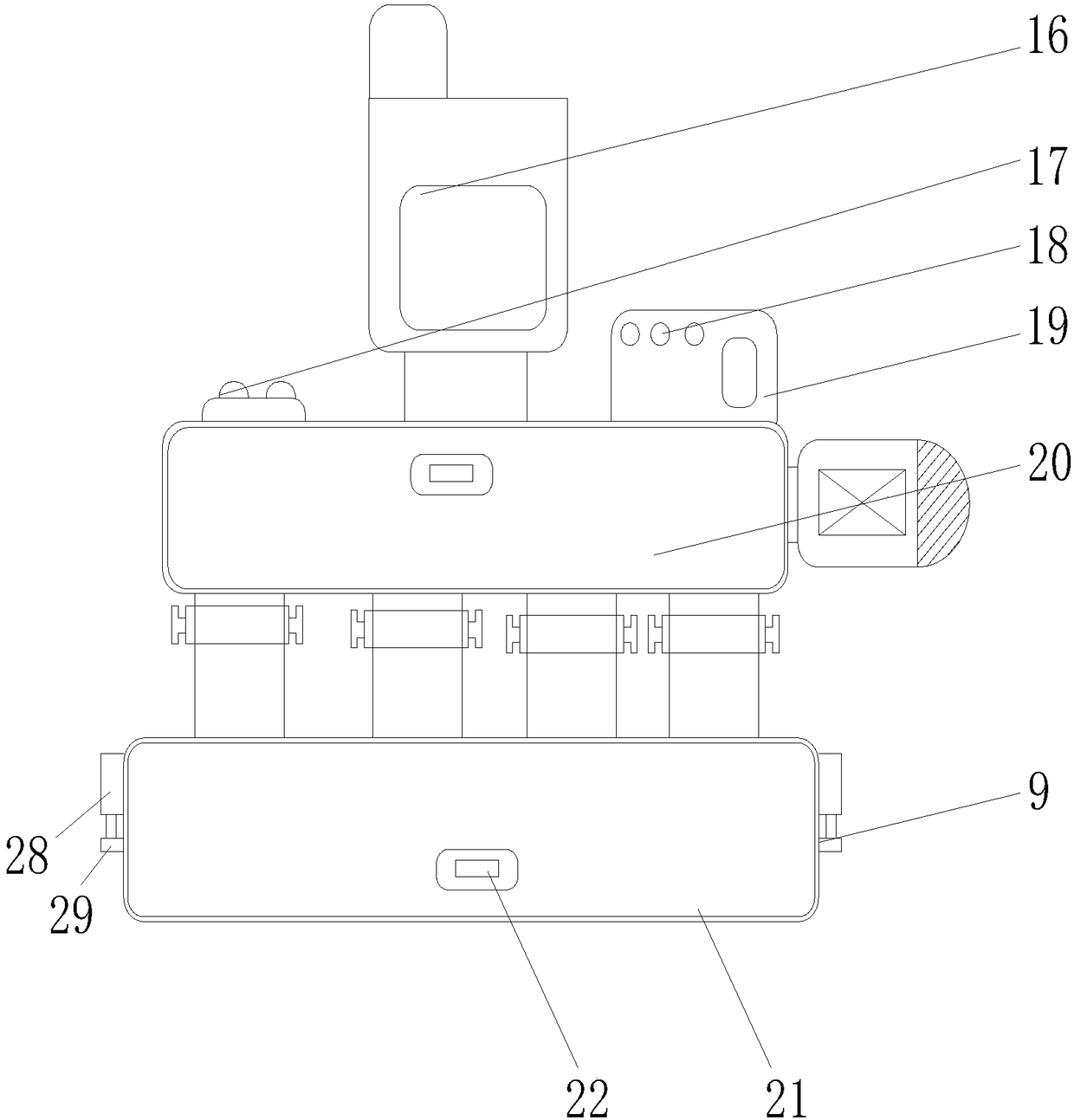

[0020] Such as Figure 1-3 As shown, the pig breeding equipment includes a storage bin 4, a mixing bin 5 and a feeding bin 9, the top of the mixing bin 5 communicates with the bottom of the storage bin 4 through a feed pipe 14, and the bottom The feeding tube 8 communicates with the top of the feeding bin 9, the feeding bin 9 is provided with a sealing cover 21 opened and closed by the second electric cylinder 28, and the mixing bin 5 is rotatably provided with a stirring Shaft 12, the outer wall of the stirring shaft 12 located in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com