Powder mill used for freeze-dried fruit powder

The technology of a pulverizer and dried fruit powder is applied in the field of food processing to achieve the effects of convenient operation, reasonable structure design and prevention of exudation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

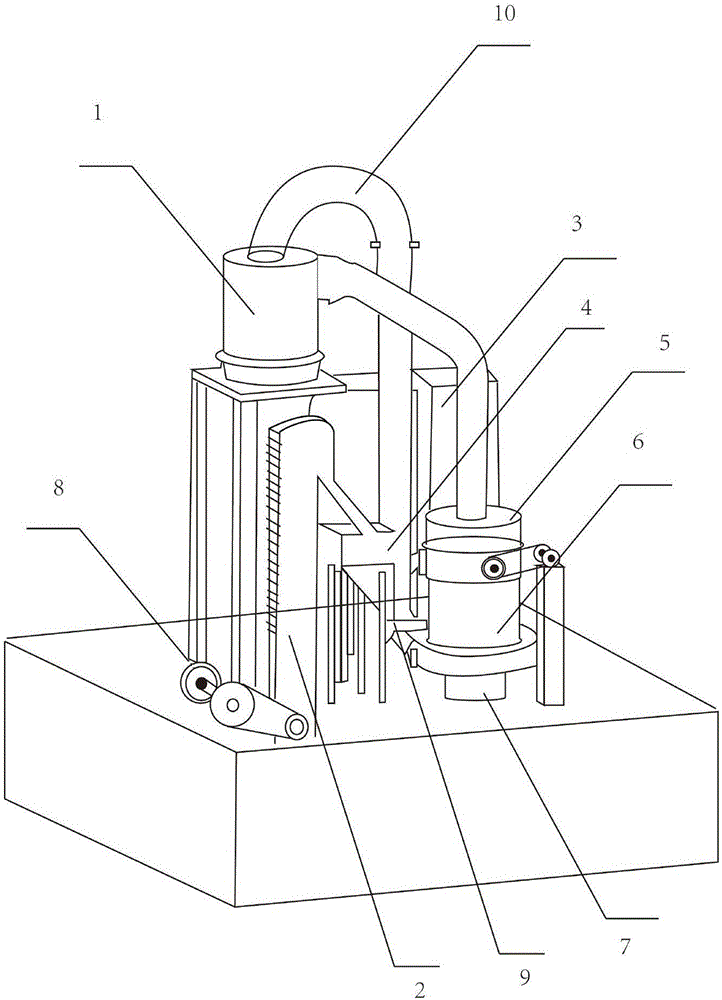

[0017] Embodiment 1: A mill for freeze-dried fruit powder, comprising a powder collector 1, a hoist 2, a dust collector 3, a silo 4, a sorter 5, a switchboard assembly 6, a reducer 7, a jaw Crusher 8 and feeder 9, the jaw crusher 8 is used for crushing freeze-dried fruit and vegetable slices, crushing it into vegetable powder, the jaw crusher 8 is connected to the elevator 2, and the fruits and vegetables are crushed by lifting the elevator 2 The powder is transported to the silo 4, one end of the silo 4 is connected to the air duct 10, and the other end is connected to the feeder 9, and the fruit and vegetable powder enters the host assembly 6 through the feeder, and the feeder is an electromagnetic vibration feeder. Feeding machine, to speed up the material entering the Zhu machine assembly, the main engine assembly 6 is electrically connected to the reducer 7, which acts as a deceleration to the main engine assembly, and the top of the main engine assembly is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com