Novel coal mine bracket

A coal mine, a new type of technology, applied in the field of new coal mine brackets, can solve the problems of safety accidents, inability to use, loss, etc., and achieve the effects of avoiding safety accidents, moving conveniently, and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

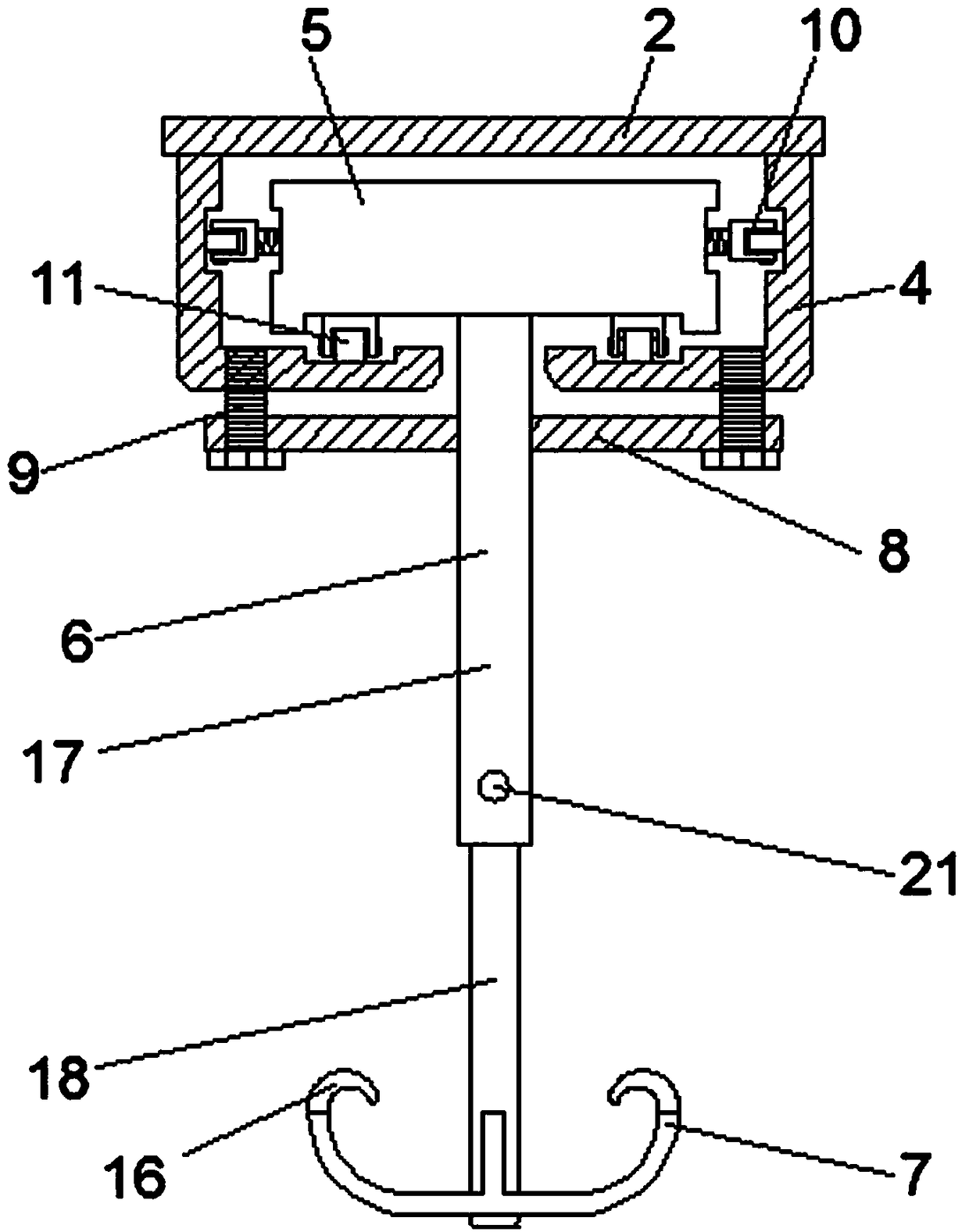

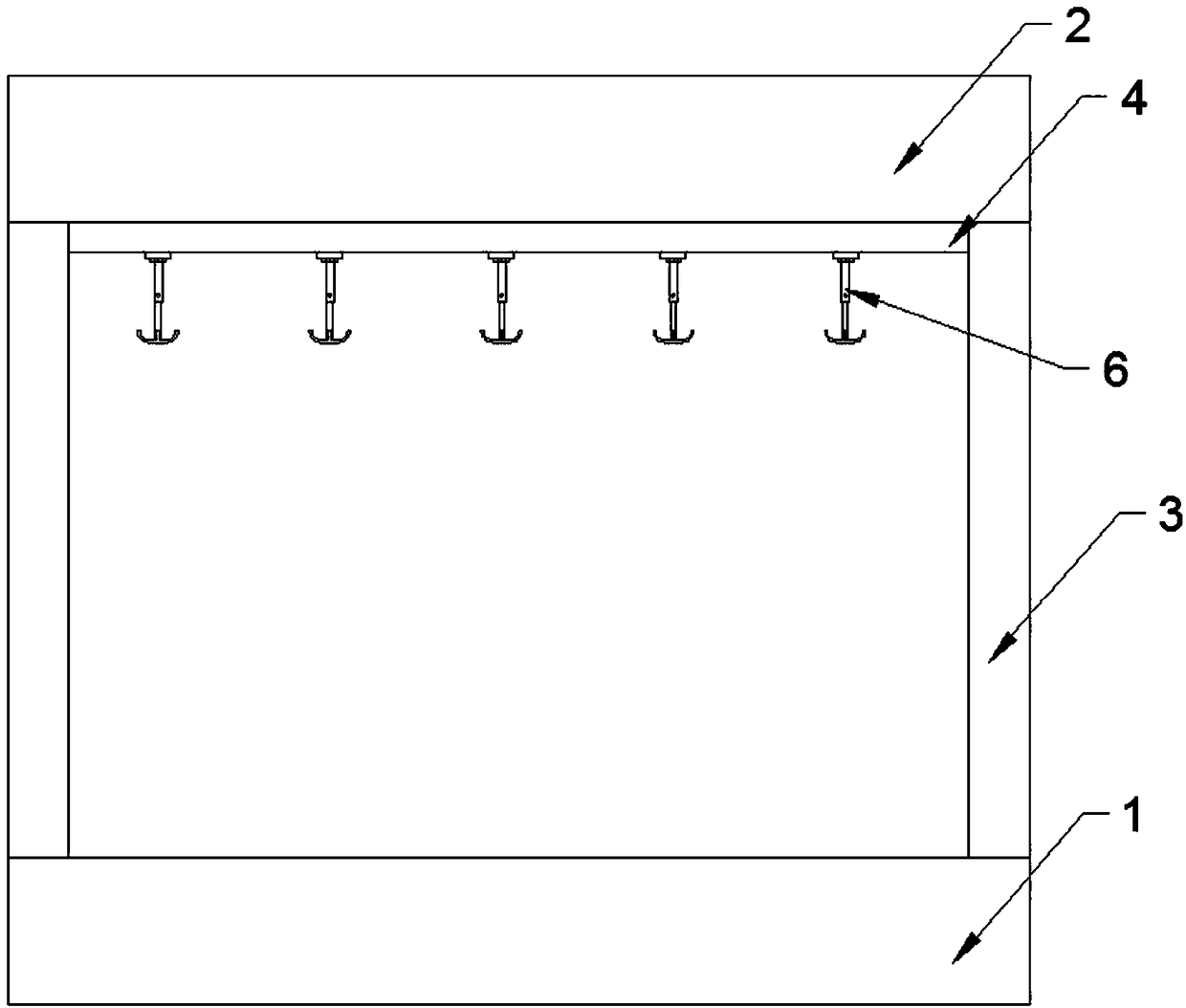

[0027] A new type of support for coal mines, including a base 1 and a crossbar 2 arranged on the base 1, a connecting rod 3 is vertically arranged between the base 1 and the crossbar 2, and a rail 4 is horizontally arranged at the bottom of the crossbar 2, and the rail 4 is provided with a plurality of suspension devices that can slide along the track 4. The suspension device includes a body 5, a hanging rod 6 arranged at the bottom of the body 5, and a hook 7 arranged at the bottom of the hanging rod 6; both sides of the hanging rod 6 are located at the bottom of the track 4 A connecting plate 8 is arranged horizontally, and a through hole is arranged on the connecting plate 8, and a connecting hole is arranged on the corresponding through hole on the track 4, and the through hole and the connecting hole are connected by a bolt 9;

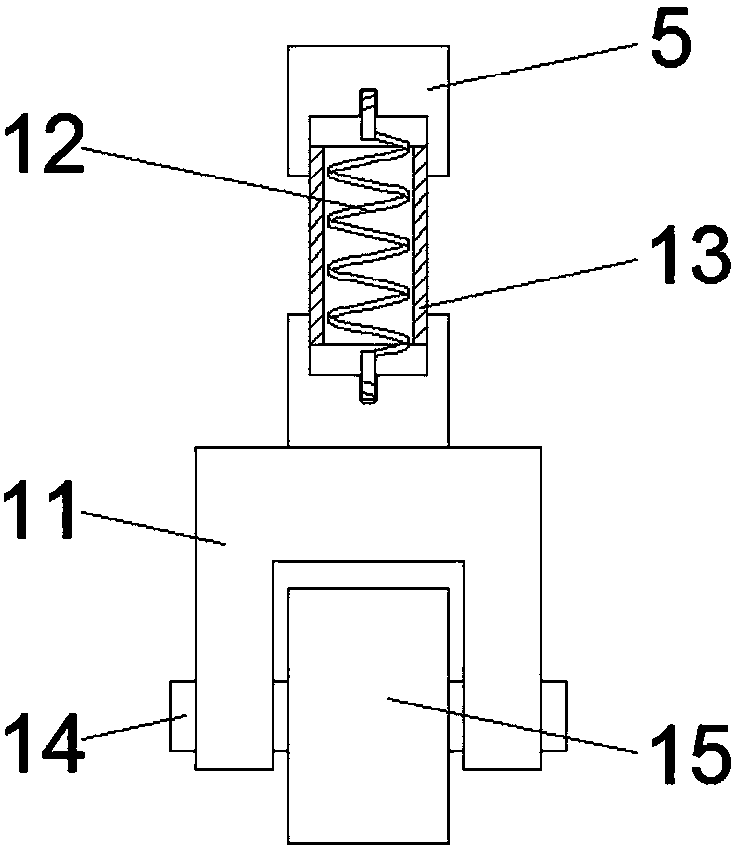

[0028] The body 5 is stuck in the track 4, and both sides below the body 5 are provided with longitudinal wheels 10, and both sides of the body 5 ...

Embodiment 2

[0030] This embodiment is further optimized based on Embodiment 1. The hanging rod 6 includes a hollow outer rod 17 arranged at the bottom of the body 5, a solid inner rod 18 arranged below the hollow outer rod 17, and the interior of the hollow outer rod 17 passes through a central axis 19. A clamping rod 20 is provided, and a button 21 is disposed above one end of the clamping rod 20 , and a second return spring 22 is disposed below one end of the clamping rod 20 , so that the length of the hanging rod 6 can be adjusted as required.

Embodiment 3

[0032] This embodiment is further optimized based on Embodiment 2. The solid inner rod 18 is evenly provided with grooves 23 on the side of the clamp rod 20. After 20 is fixed, due to the excessive external force, the clamping rod 20 and the solid inner rod 18 will slide relative to each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com