A filter tank pressure stabilization energy dissipation and material leakage diagnosis system and method

A diagnostic system and energy dissipation technology, applied in chemical instruments and methods, separation methods, loose filter material filters, etc., can solve problems such as the top plate of the filter plate or the pressure block of the filter plate falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] By referring to exemplary embodiments, the objects and functions of the present invention and the methods for achieving these objects and functions will be clarified. However, the present invention is not limited to the exemplary embodiments disclosed below; it can be implemented in different forms. The essence of the description is only to help those skilled in the relevant art to comprehensively understand the specific details of the present invention.

[0023] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In the drawings, the same reference signs represent the same or similar parts or the same or similar steps.

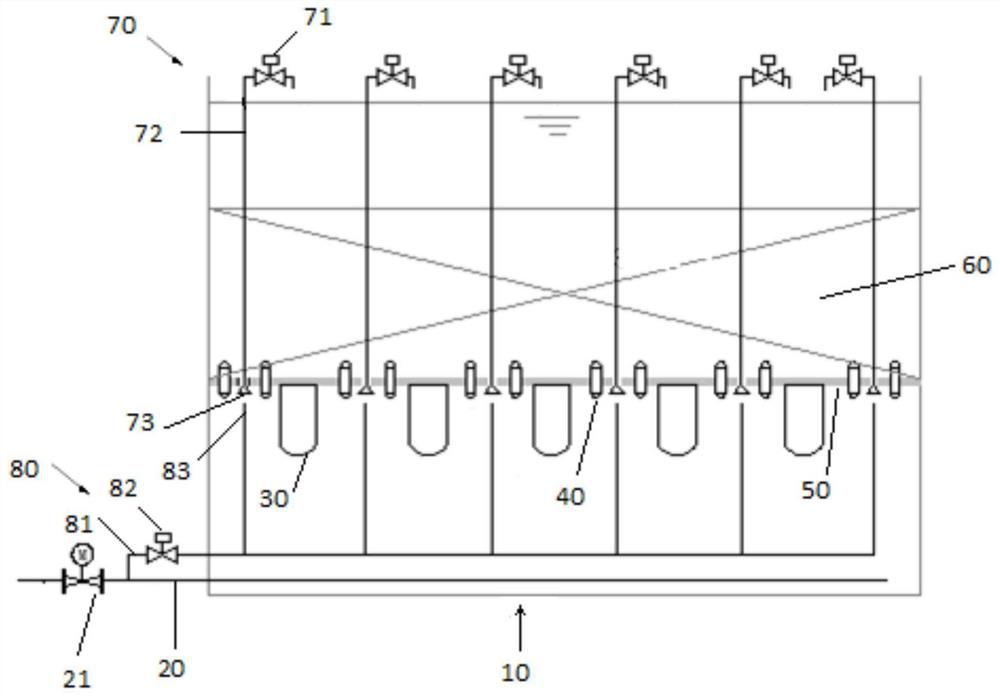

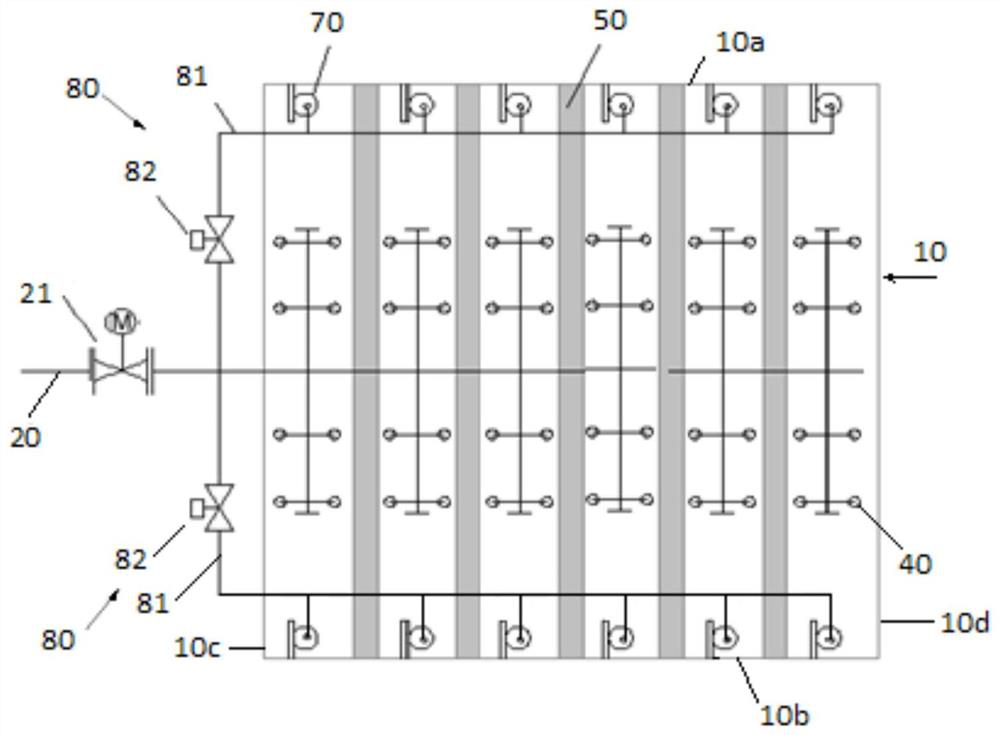

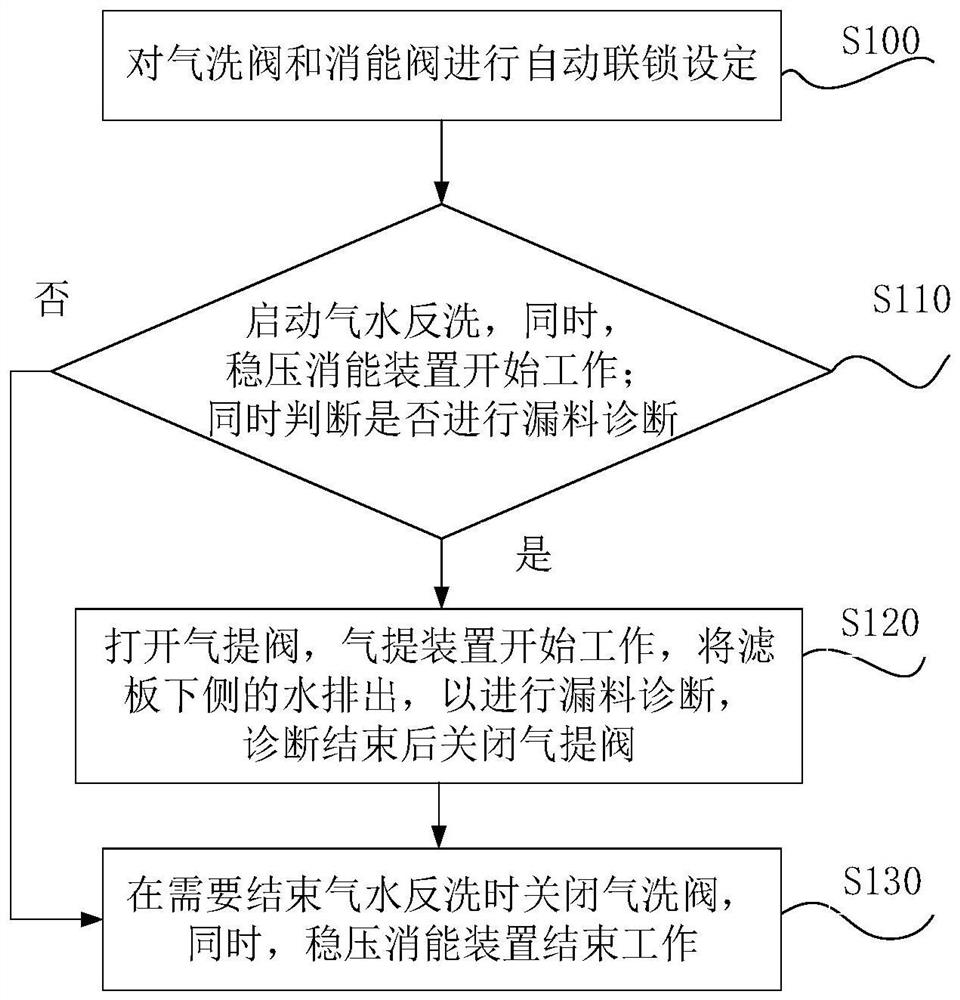

[0024] In order to better understand the present invention, below, first combine figure 1 A brief description of the basic structure of the filter.

[0025] Such as figure 1 As shown, in the filter tank 10, a filter head 40 is used as a water distribution and air distribution channel. The filter head 40 is ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com