Center stand column reinforcing plate welding and cooling method

A cooling method and reinforcement plate technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems affecting the performance of column reinforcement plates, achieve the effects of preventing stress changes and accelerating heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

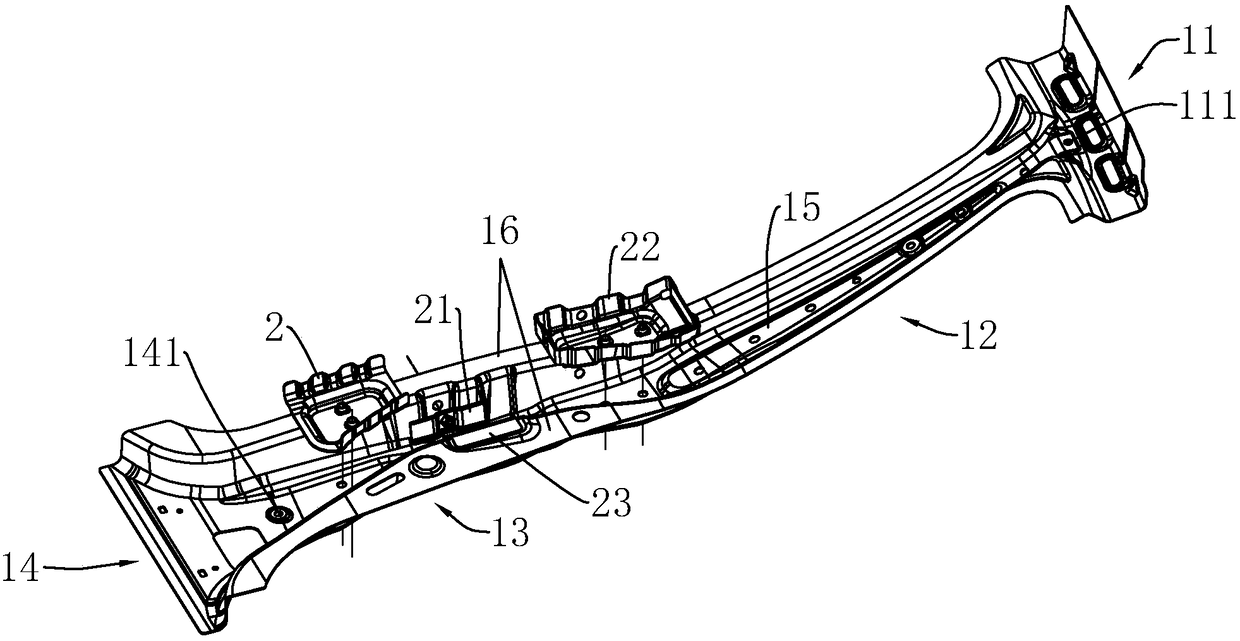

[0060] This embodiment provides a method for welding and cooling a central pillar reinforcement plate, the structure of which is shown in the figure.

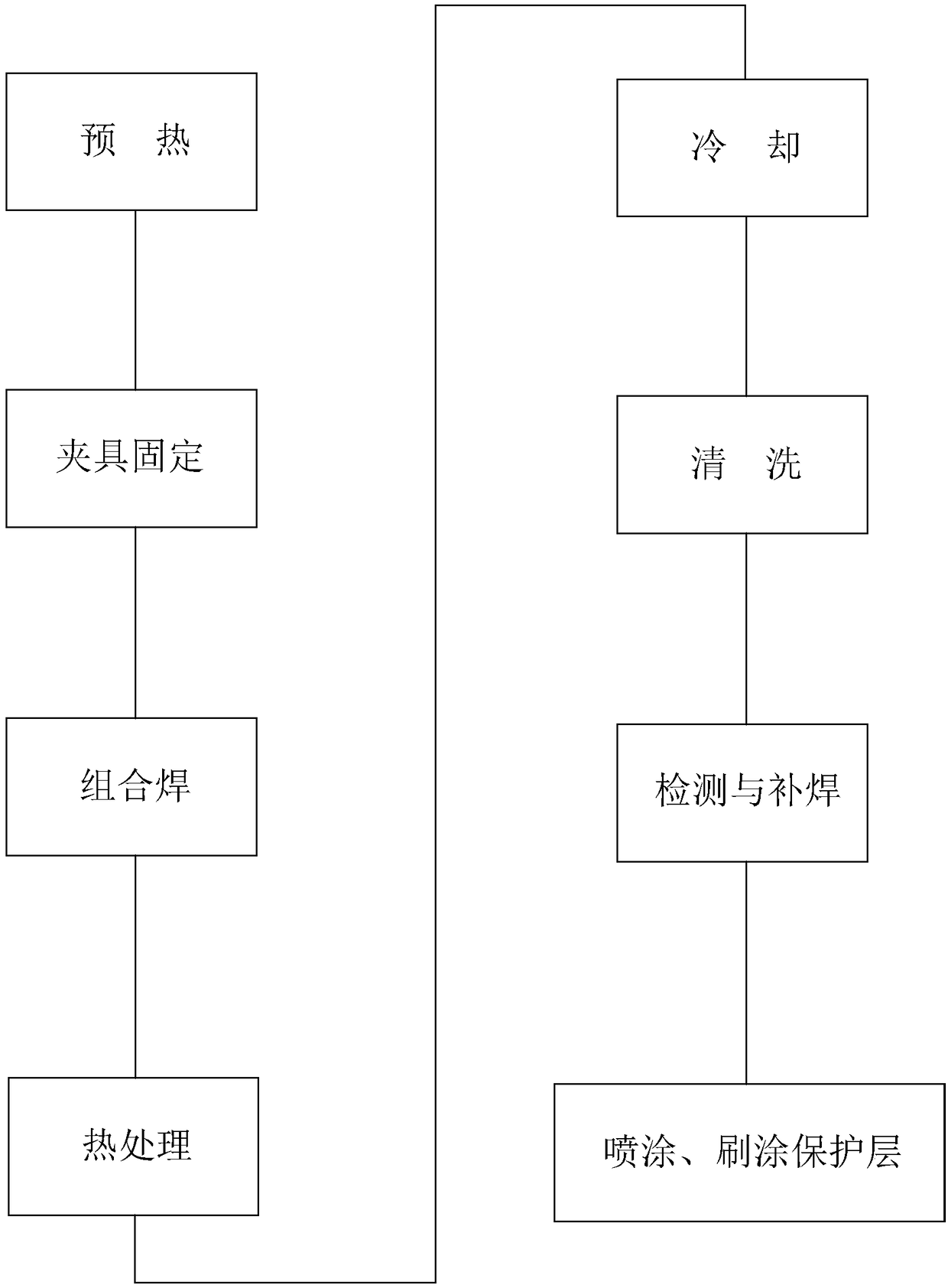

[0061] The welding cooling method of the center pillar reinforcement plate,

[0062] S1: Preheating, respectively put the center column reinforcement plate and the weldment to be welded into the heating chamber for a certain period of time, so that the temperature of the center column reinforcement plate and the weldment to be welded can be increased;

[0063] S2: The fixture is fixed, and the preheated center column reinforcement plate and the weldment to be welded are fixed by the welding fixture, so that the weldment to be welded is positioned at the position to be welded;

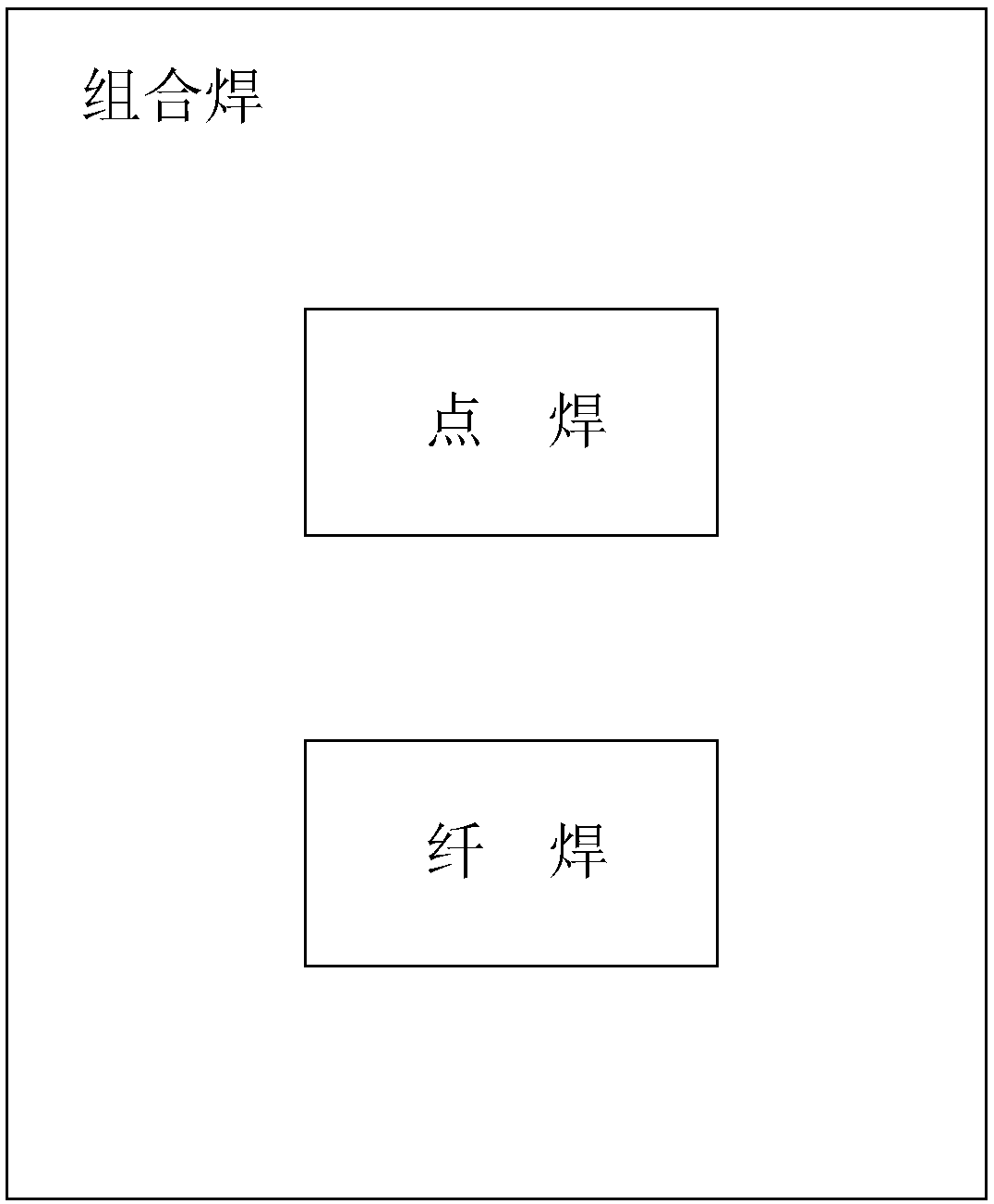

[0064] S3: combined welding,

[0065] S3': Simultaneous partial welding of the first weldment, the fourth weldment and the third weldment;

[0066]S3″: Weld the remaining parts that need to be welded on the first weldment, the second weldment and the t...

Embodiment 2

[0094] A method for welding and cooling a center pillar stiffener, the difference from Embodiment 1 is:

[0095] S3′: When performing local welding on the first weldment, the edge close to the right side of the gentle section on the first weldment is welded, and the brazing welding method is adopted;

[0096] Fix the second weldment by spot welding;

[0097] When performing partial welding on the third weldment, the edge close to the right side of the gentle section on the third weldment is welded, and the spot welding method is adopted;

[0098] S3″: Weld the edge of the first weldment close to the left side of the gentle section by spot welding;

[0099] The fourth weldment is welded and fixed by fiber welding;

[0100] For the third weldment close to the left side of the gentle section, spot welding is adopted.

Embodiment 3

[0102] A welding process for the reinforcement plate of the central pillar frame, the difference from Example 1 is: S1: preheating, respectively put the reinforcement plate of the central pillar and the weldment to be welded into the heating chamber for a certain period of time, so that the reinforcement plate of the central pillar and the The temperature of the weldment to be welded is increased. The specific operation method is:

[0103] F1: First put the center column reinforcement plate and the weldment to be welded into the heating chamber, keep the temperature in the heating chamber at 300°C, and place it for no less than 2 hours;

[0104] F2: Take out the center pillar reinforcement plate and install it on the welding fixture;

[0105] F3: Use a hot gun to blow air on the central column reinforcement plate, and reciprocate the air along the length of the central column reinforcement plate. After blowing the side with the groove, blow the other side of the central colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com