Double-screw extruder with forced material mixing structure

A technology of twin-screw extruder and screw, which is applied in the field of twin-screw extruder to achieve uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

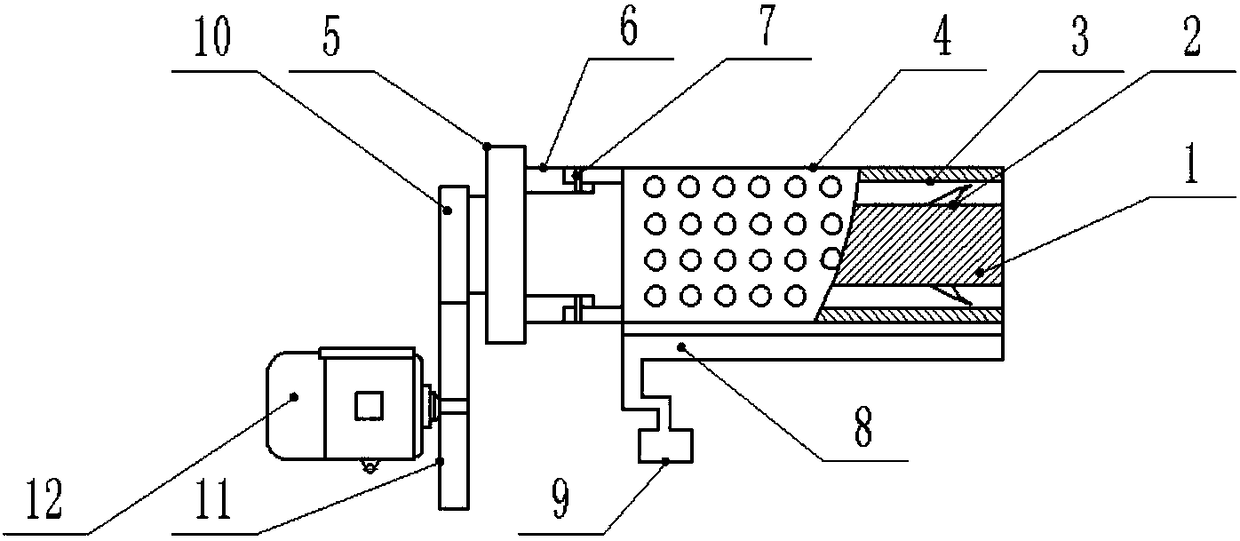

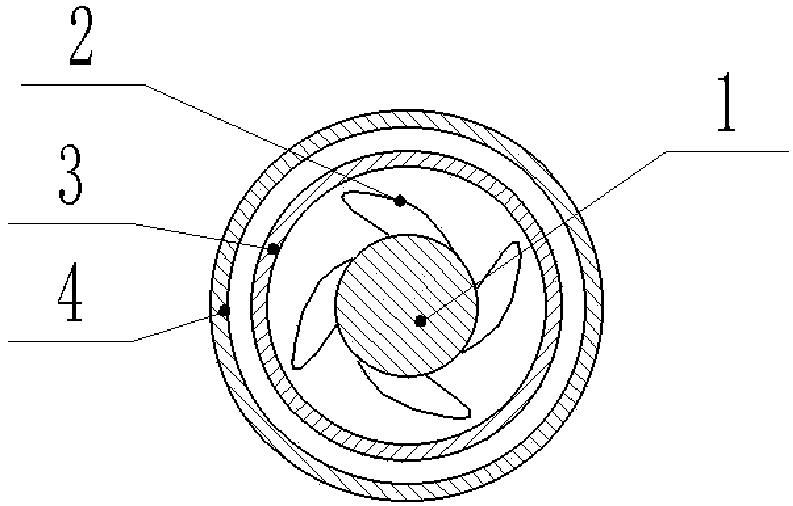

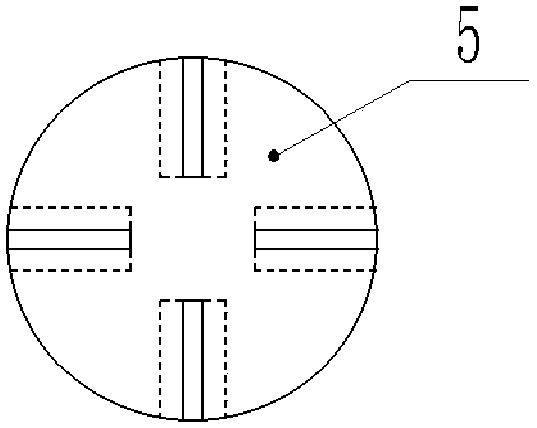

[0021] like figure 1 , a twin-screw extruder with a forced mixing structure includes: a motor (12) to control the rotation of a cylindrical device, a gear (11) connected to the motor, a gear (10) connected to a disc, a fixed cylindrical device The disc (5) of the device, the device (6) of the circular device connecting the disc, the blade mechanism (2), the inner cylindrical device (3), the outer cylindrical device (4), and the external impurity collector ( 9), bolts, nuts and washers (7).

[0022] like figure 1 , 2, 3, 4, the cylindrical device (3) (4) and the blade mechanism (2) are at the front end of the screw conveying section, when the twin-screw extruder is started, the inner cylinder is controlled at the same time The motors of the cylindrical device (3) and the outer cylindrical device (4) start to run to drive the inner cylindrical device (3) and the outer cylindrical device to work, and one motor can be used to control a cylindrical device alone, or a A motor and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com