Longitudinal-torsional composite piezoelectric vibration disc, method and application

A technology of piezoelectric vibration and vertical torsion, which is applied in vibrating conveyors, transportation and packaging, conveyors, etc., can solve the problems of low vibration power and achieve the effects of low operating frequency, low power consumption, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will now be further described in conjunction with the drawings and embodiments.

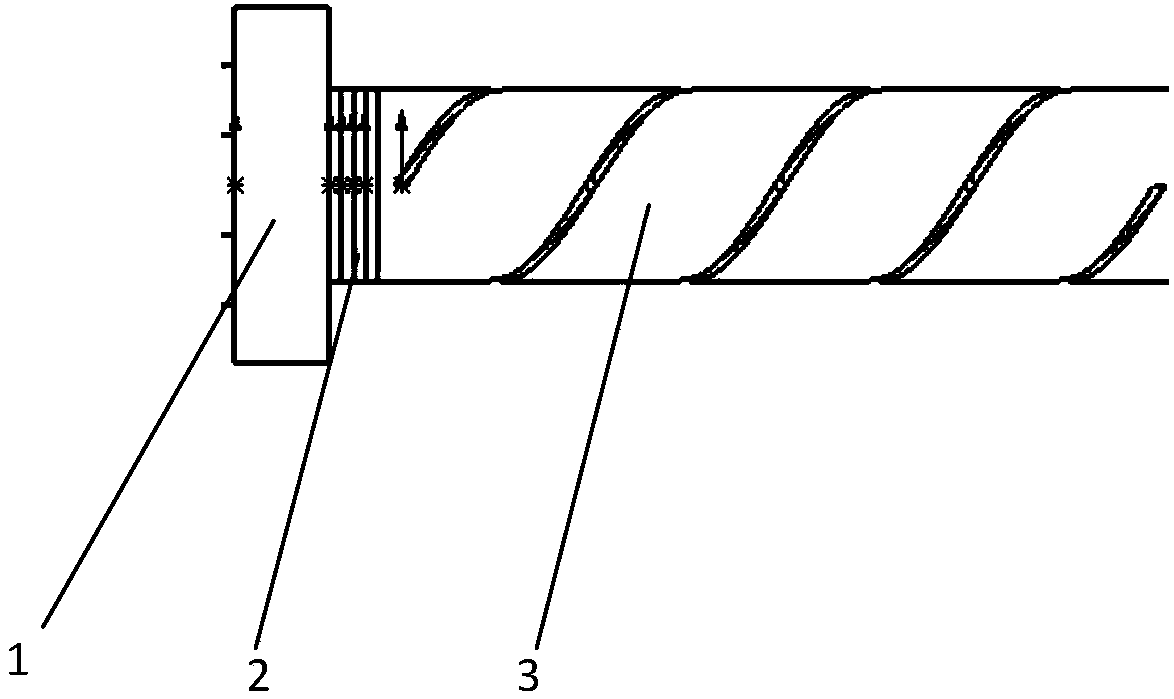

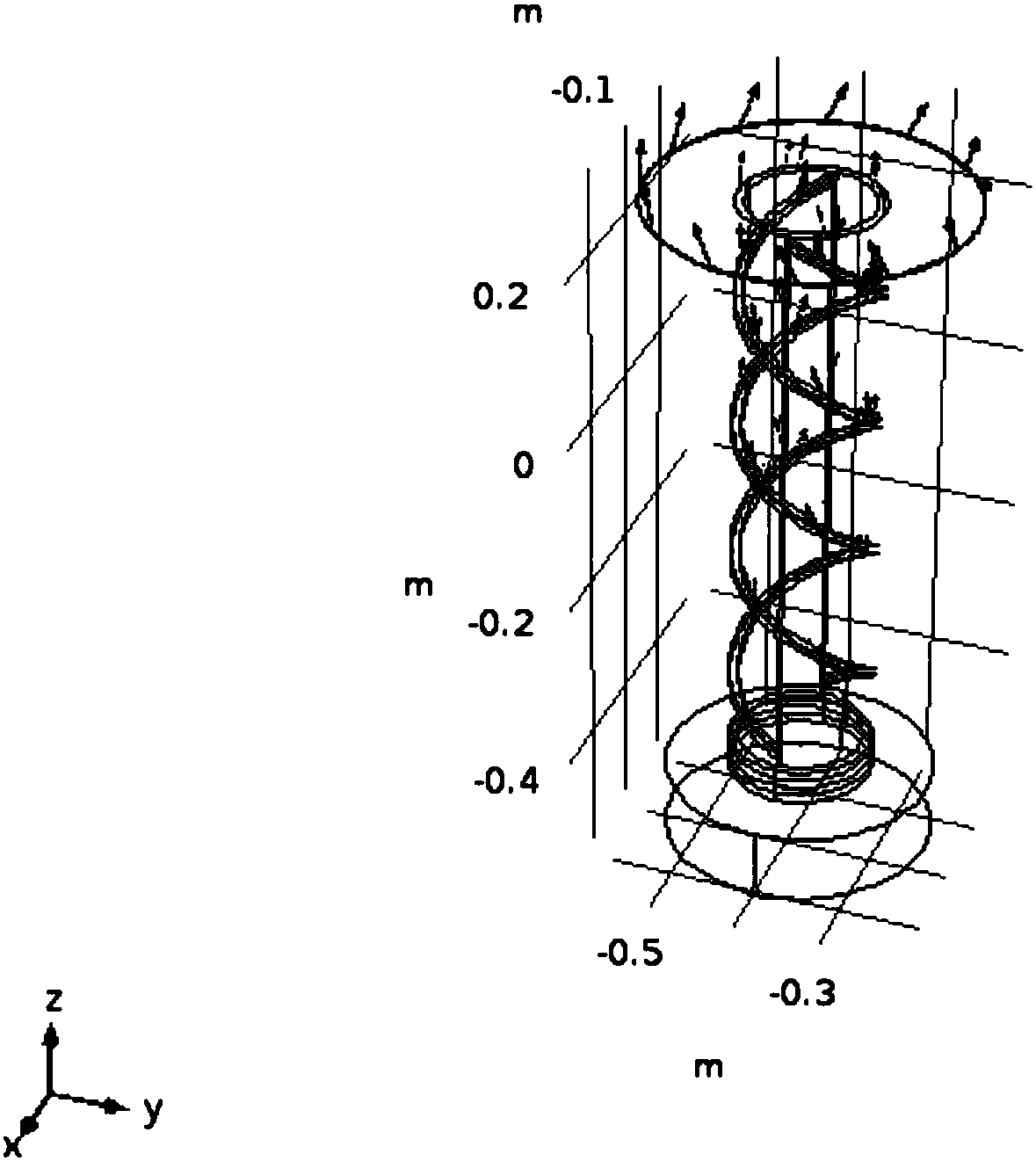

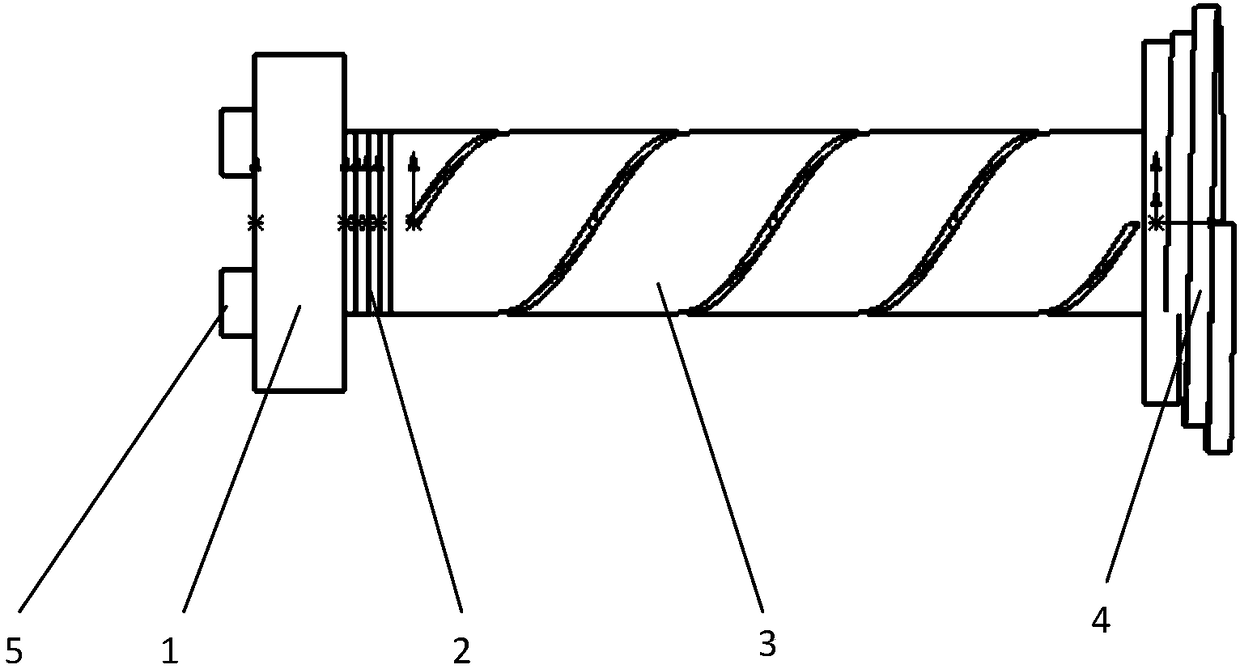

[0034] Such as figure 1 As shown, the longitudinal-twisting composite piezoelectric vibrating disk of this embodiment is composed of a piezoelectric ceramic stack 2, a slotted round tube 3 and a mass base 1, and the slotted round tube 3 is arranged on the longitudinal polarization of the piezoelectric ceramic stack 2. direction, that is, the axis of the slotted circular tube 3 extends along the longitudinal polarization direction of the piezoelectric ceramic stack 2 , and the slotted circular tube 3 is arranged coaxially with the piezoelectric ceramic stack 2 and the mass base 1 in sequence. The piezoelectric ceramic stack 2 is composed of four piezoelectric ceramic discs with the same thickness and the same polarization direction fixed together by screws. The piezoelectric ceramic discs are made of PZT-4 piezoelectric ceramics, with a diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com