Feeding system capable of synchronously conveying multiple sets of ceramic columns with different specifications

A technology of simultaneous conveying and feeding system, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of unstable transmission process of porcelain columns, unstable feeding, low transmission accuracy, etc., to improve the material receiving and conveying. Efficiency, reduced production cost, high intelligence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

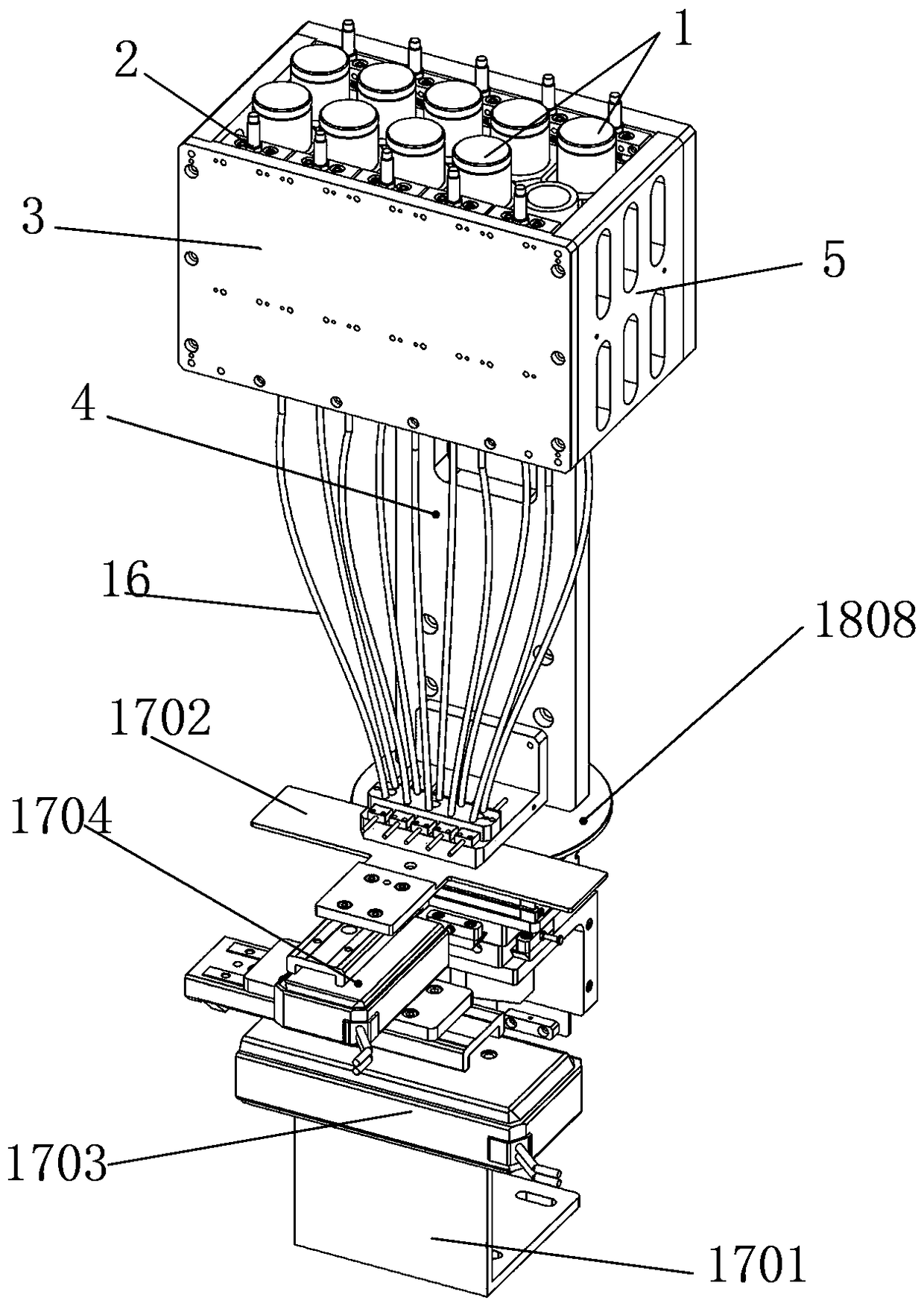

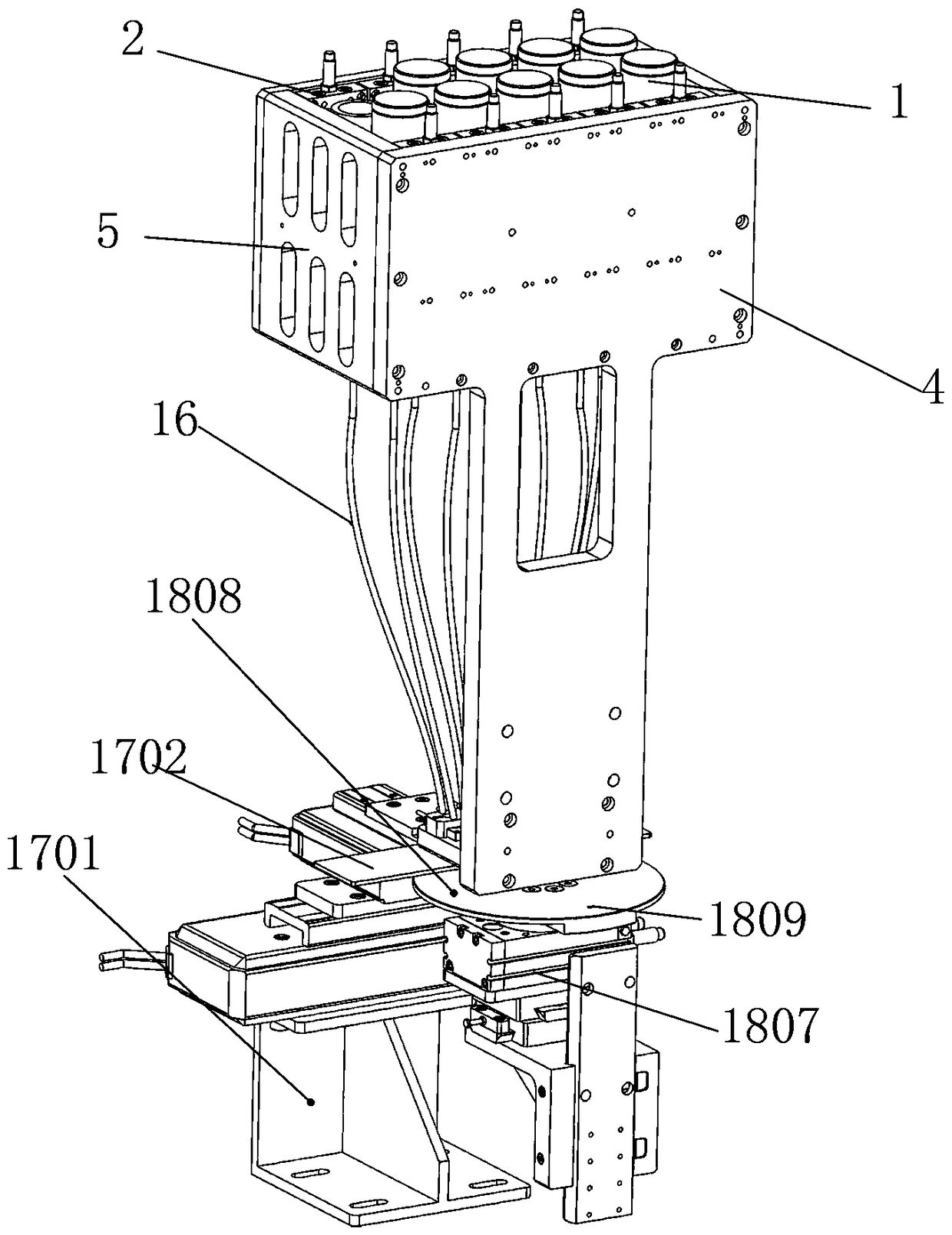

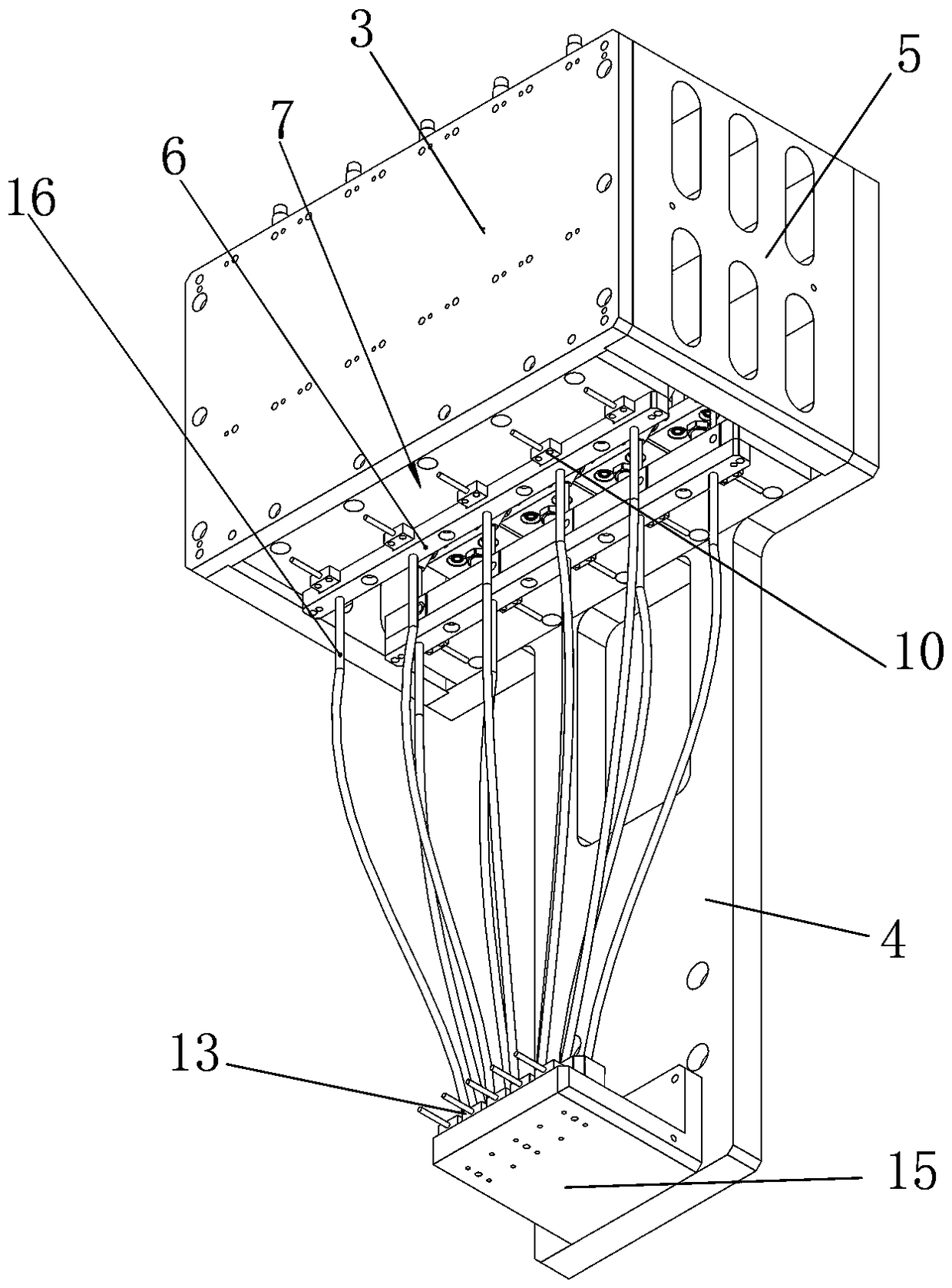

[0038] In this embodiment, refer to Figure 1-Figure 10 , its specific implementation can simultaneously transmit multiple groups of ceramic column feeding systems of different specifications including a feeding mechanism, a material receiving mechanism 17 and a feeding mechanism 18, such as figure 1 and figure 2 As shown, the feeding mechanism is located above the material receiving mechanism 17, and the feeding mechanism 18 is located at the rear of the material receiving mechanism 17. The feeding mechanism is used for storing and supplying porcelain columns, and the material receiving mechanism 17 is used for accepting the porcelain columns supplied by the feeding mechanism. column, and accurately delivered to the feeding mechanism 18, the feeding mechanism 18 is used to deliver the ceramic column to the automatic assembly proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com