Method and device capable of realizing deflection, turn-over and transposition of carrying pole beams of aqueduct erecting machine in air

A shoulder pole beam and slotting machine technology, which is applied in the direction of transportation, packaging, load hanging components, etc., can solve the technical problems of pole beam removal and turnover construction, and achieve the simplification of hoisting and installation process, economical and reasonable, and reduce a lot of costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

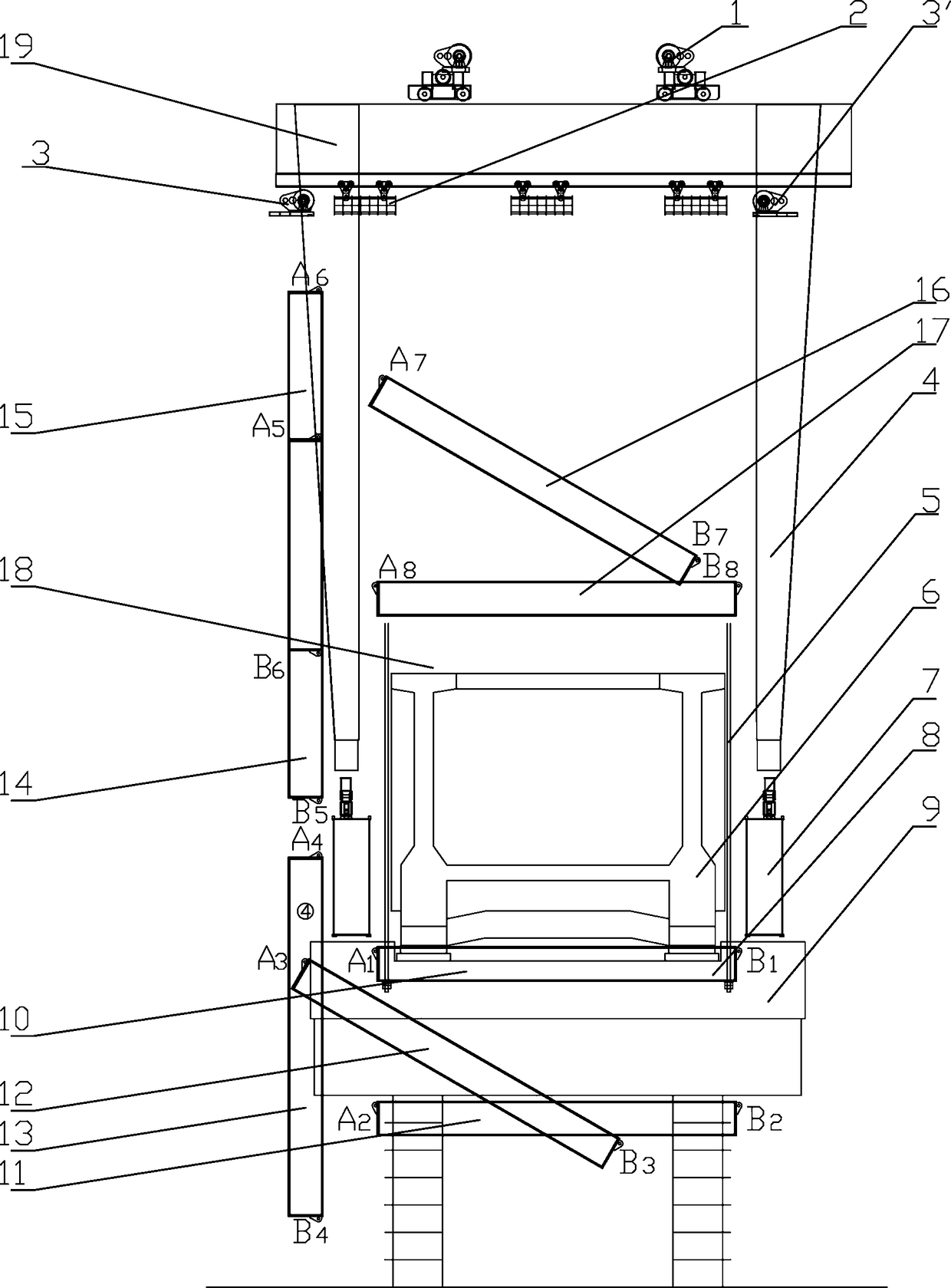

[0036] Such as Figure 1~3 Among them, a method for deflecting and turning over in the air with a shoulder pole beam of a slotting machine is characterized in that it includes the following steps:

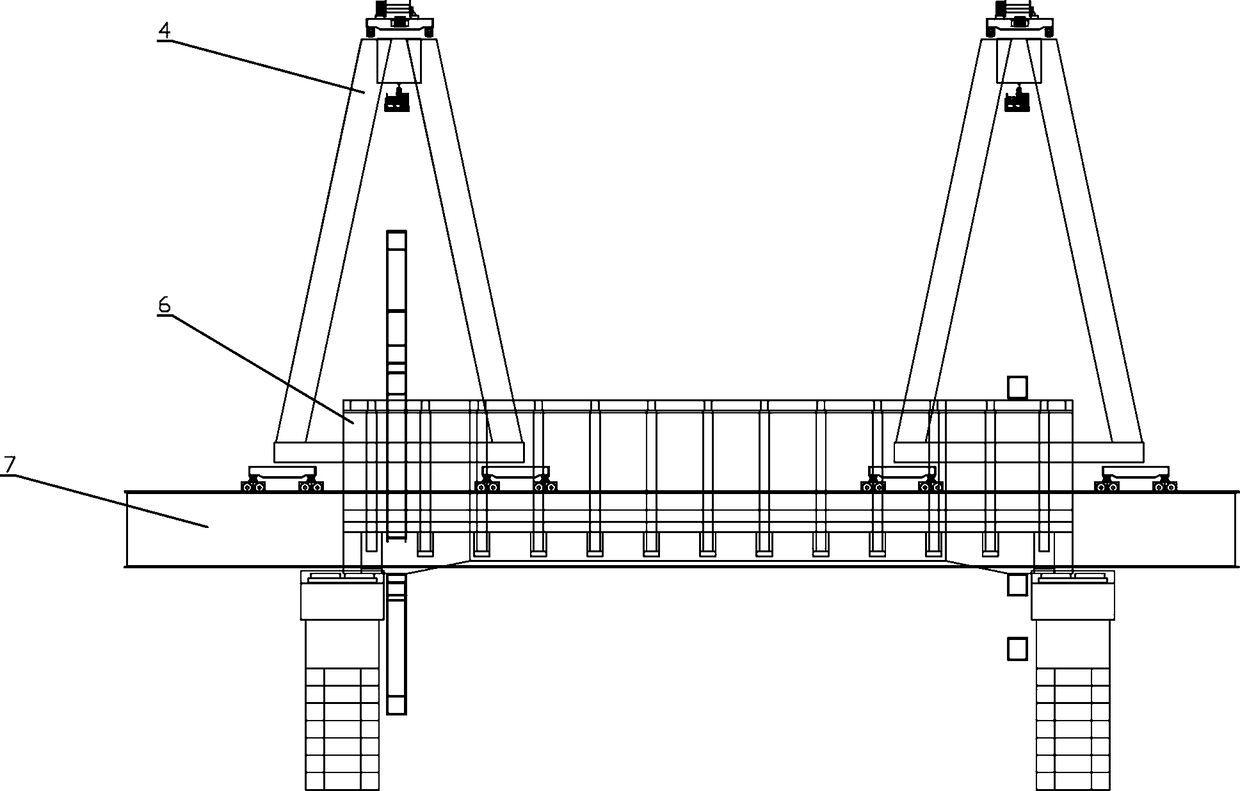

[0037] s1, the hoisting platform is set on the hoisting machine legs 4 on both sides of the slotting machine, the first hoisting machine 3 and the second hoisting machine 3' are respectively set on the hoisting platforms on both sides, and the bottom of the slotting machine beam 19 is set With electric hoist 2;

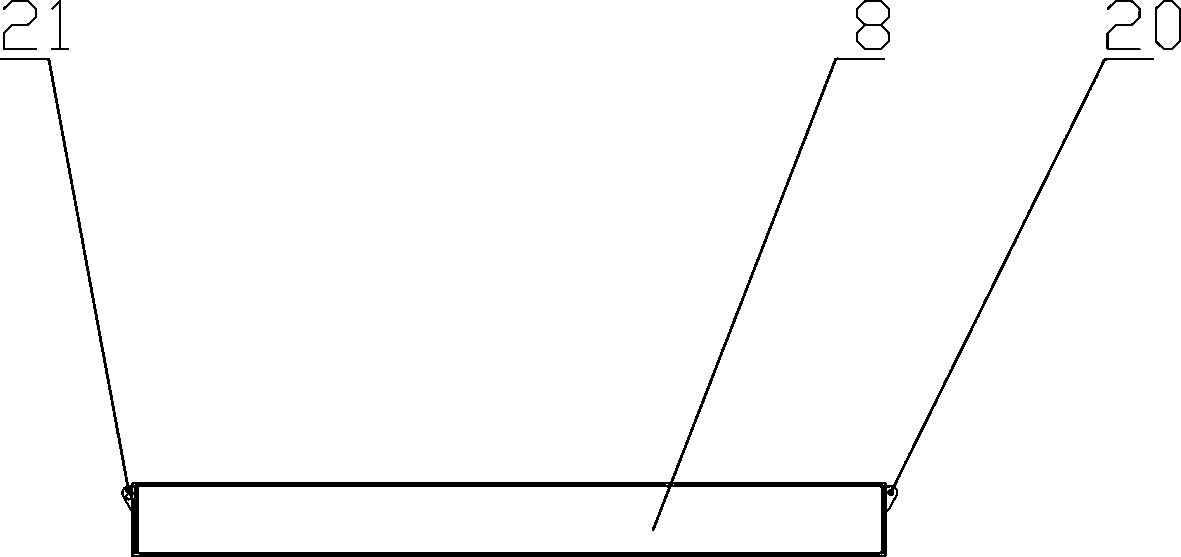

[0038] s2. Operate the hook of the second winch 3' and drop it from between the aqueduct body 6 and the door machine guide beam 7 on the right to connect with the single-hole lifting lug 20 of the pole beam 8, that is figure 1 In the B1 end, the hook for operating the electric hoist 2 falls from between the aqueduct body 6 and the left door machine guide beam 7 and connects with the upper hole of the double-hole lifting lug 21 of the pole beam 8. figure 1 In the A1 end, ...

Embodiment 2

[0053] A device used for the above-mentioned method of deflecting and turning over and transposing the shoulder pole beam of the slotting machine in the air. The hoisting platforms are arranged on the legs 4 of the slotting machine on both sides of the slotting machine, and the first hoisting platforms are respectively arranged on the hoisting platforms on both sides. The hoist 3 and the second hoist 3' are equipped with an electric hoist 2 at the bottom of the slot machine beam 19;

[0054] The first hoisting machine 3 and the second hoisting machine 3' are located between the two legs of the supporting legs 4 of the racking machine;

[0055] The drum centerlines of the first hoist 3 and the second hoist 3 ′ are parallel to the centerline of the aqueduct body 6 and perpendicular to the centerline of the shoulder beam 8 . The center of the hoist drum and the center of the steel suspender 5 are staggered with an appropriate distance to prevent interference friction between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com