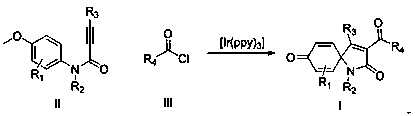

Preparation method of 3-acyl screw ring dibenzosuberenone compound

A kind of technology of acyl spirocyclic trienone and compound, which is applied in the field of preparation of 3-acyl spirocyclic trienone compound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-17

[0036] Embodiment 1-17 Reaction condition optimization:

[0037] Using alkyne amide and benzoyl chloride shown in formula three as raw materials, the influence of various conditions on the reaction (formula two) was explored, and representative examples were selected. The results are shown in table one:

[0038] Example

Reaction condition (variable)

Yield (%)

1

---

88

2

[Ru(bpy) 3 Cl 2 ] instead of [Ir(ppy) 3 ]

0

3

Eosin Y instead of [Ir(ppy) 3 ]

0

4

Do not join [Ir(ppy) 3 ]

0

5

in the dark

0

6

[Ir(ppy) 3 ] Feed amount is replaced by 5 mol %

89

7

36W fluorescent lamp replaces the LED lamp in Example 1

73

8

Na 2 CO 3 Instead of 2,6-lutidine

53

9

K 2 CO 3 Instead of 2,6-lutidine

47

10

Et 3 N instead of 2,6-lutidine

51

11

Toluene instead of CH 3 CN

32

12

BuOAc instead of CH 3 CN

61

...

Embodiment 18

[0046] Example 18 target product Synthesis

[0047] Add a magnetic stirring bar to the reactor, add the corresponding alkyne amide compound (0.2mmol) (refer to the reaction formula of formula 1 for the structure), photocatalyst [Ir(ppy) 3 ] (2mol%) and 2,6-lutidine (2.0 equivalents), then add benzoyl chloride (0.4mmol) and organic solvent acetonitrile (2mL), then replace the air in the reactor with argon to replace 3- After 5 times, the reactor was then placed in an oil bath equipped with magnetic stirring at a temperature of 100° C., and heated for 24 hours under the light condition of a 5W blue LED lamp as the light source. After the reaction was complete, the solvent was evaporated to dryness with a rotary evaporator, and the residue was separated and purified with a chromatographic column to obtain the target product with a yield of 83% ( 1 H NMR (400 MHz, CDCl 3 ): 7.84 (d, J = 7.6 Hz, 2H), 7.52(t, J = 8.0 Hz, 1H), 7.38 (t, J = 8.0 Hz, 2H), 7.23 (s, 5H), 7.22-7....

Embodiment 19

[0048] Example 19 target product Synthesis

[0049] Add a magnetic stirring bar to the reactor, add the corresponding alkyne amide compound (0.2mmol) (refer to the reaction formula of formula 1 for the structure), photocatalyst [Ir(ppy) 3 ] (2mol%) and 2,6-lutidine (2.0 equivalents), then add benzoyl chloride (0.4mmol) and organic solvent acetonitrile (2mL), then replace the air in the reactor with argon to replace 3- After 5 times, the reactor was then placed in an oil bath equipped with magnetic stirring at a temperature of 100° C., and heated for 24 hours under the light condition of a 5W blue LED lamp as the light source. After the reaction was complete, the solvent was evaporated to dryness with a rotary evaporator, and the residue was separated and purified with a chromatographic column to obtain the target product with a yield of 67% ( 1 H NMR (400 MHz, CDCl 3 ): 7.85 (t, J = 4.0 Hz, 2H), 7.54(d, J = 8.0 Hz, 1H), 7.41 (t, J = 8.0 Hz, 2H), 7.28-7.20 (m, 5H), 6....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com