Vacuum drying oven connected with glove box and material obtaining method thereof

A vacuum drying furnace and vacuum drying technology, applied in the direction of drying solid materials, dryers for static materials, and drying solid materials without heating, etc., can solve the problems of high cost of drying room, secondary moisture, and the effect of lithium battery drying. problems, and achieve the effect of avoiding secondary damp and reducing construction and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and effect of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

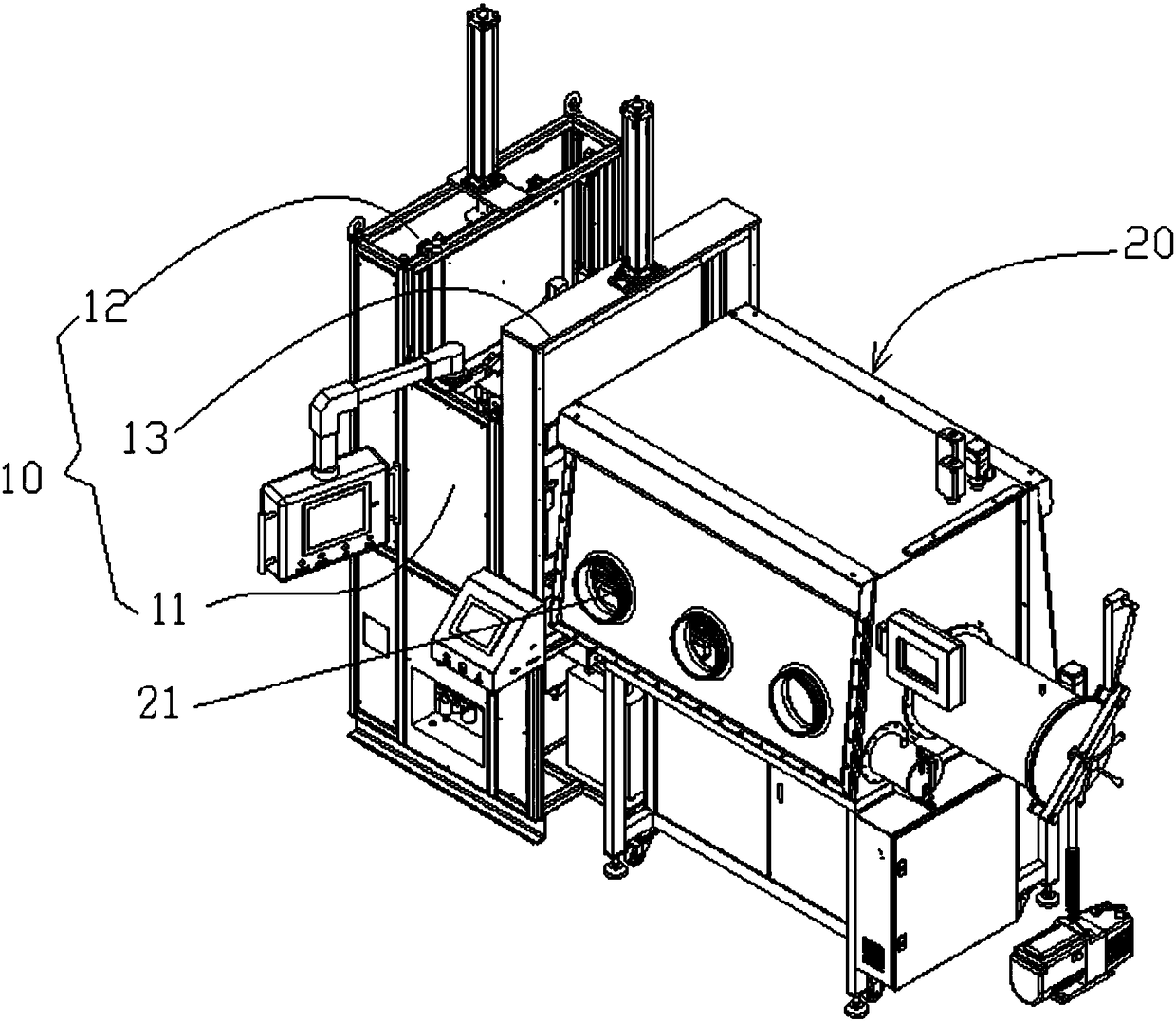

[0021] A vacuum drying oven connected to a glove box provided by the present invention, please refer to figure 1 , as shown in the figure, the vacuum drying furnace includes:

[0022] A main furnace body 10 for vacuum drying, and a glove box 20 sealed and docked with the main furnace body 10;

[0023] The main furnace body 10 includes a cavity assembly 11, a front sealing door assembly 12 arranged on one side of the cavity assembly 11 for sealing, and a sealing arrangement on the side of the cavity assembly 11 away from the front sealing door assembly 12 The rear sealed door assembly 13; t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap