Coal drying device for coal-fired power plant

A coal-fired power plant and drying device technology, applied in the direction of drying gas arrangement, dryer combination, drying chamber/container, etc., can solve problems such as low energy utilization rate, secondary moisture of coal, heat energy loss, etc., and improve energy conversion efficiency and drying effect, prevent secondary moisture, improve the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

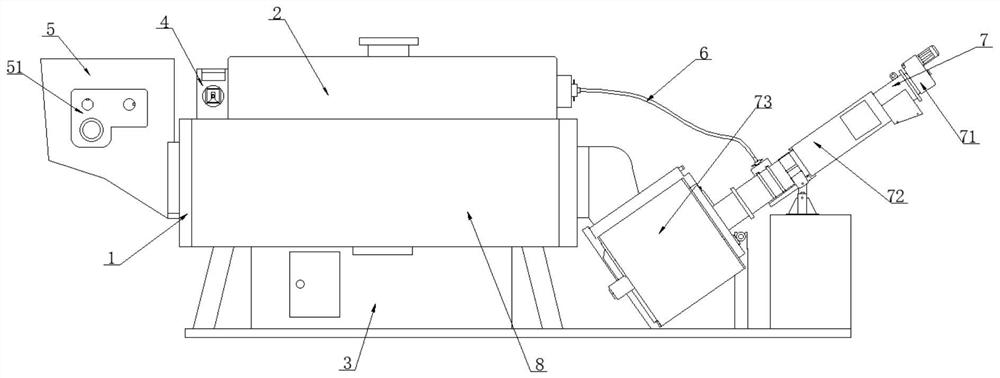

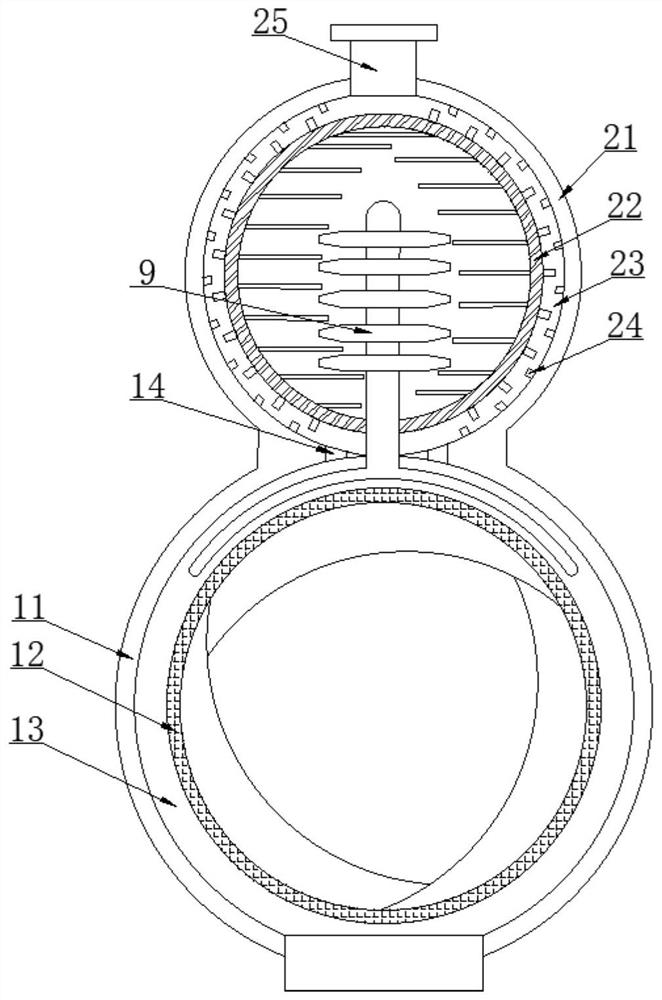

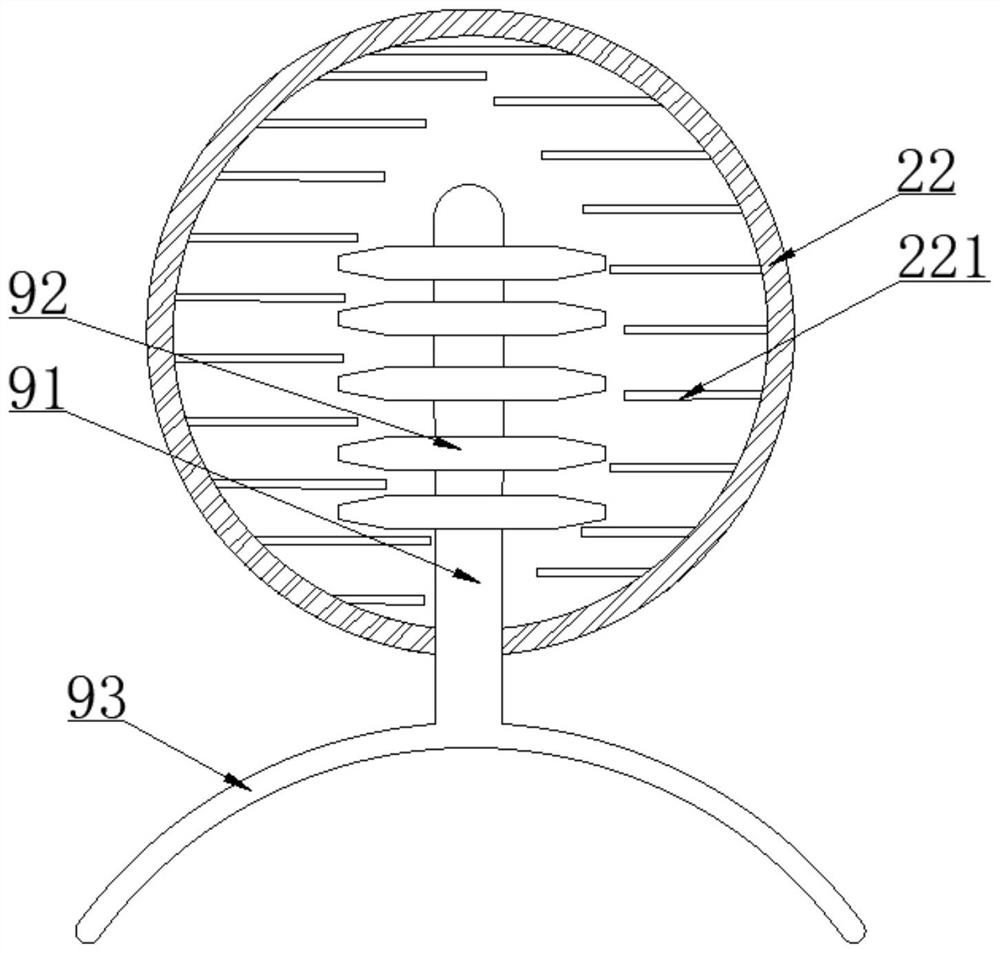

[0039] as attached Figure 1-7 The shown coal drying device for a coal-fired power plant includes a rotary drum dryer 1 and a hot blast stove 3, the output end of the hot blast stove 3 is connected to the bottom end of the rotary drum dryer 1, and one end of the rotary drum dryer 1 is fixed A crushing and filling hopper 5 is installed, and the interior of the crushing and filling hopper 5 is provided with an engaging crushing mechanism 51. The other end of the drum dryer 1 is fixedly connected with a heat preservation and conveying mechanism 7, and the top surface of the drum dryer 1 is fixedly installed with a waste heat recovery cylinder. 2. One end of the waste heat recovery cylinder 2 is fixedly installed with a dry air intake mechanism 4, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com