A method for quickly calibrating the standard grouting volume of steel half-grouting sleeves on site

A semi-grouting sleeve, fast technology, applied in the direction of volume measurement test/calibration, measurement device, test/calibration device, etc., can solve problems such as construction defects, unskilled technology, grout leakage, running grout, etc., to achieve accurate measurement Volume, convenient detection method, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

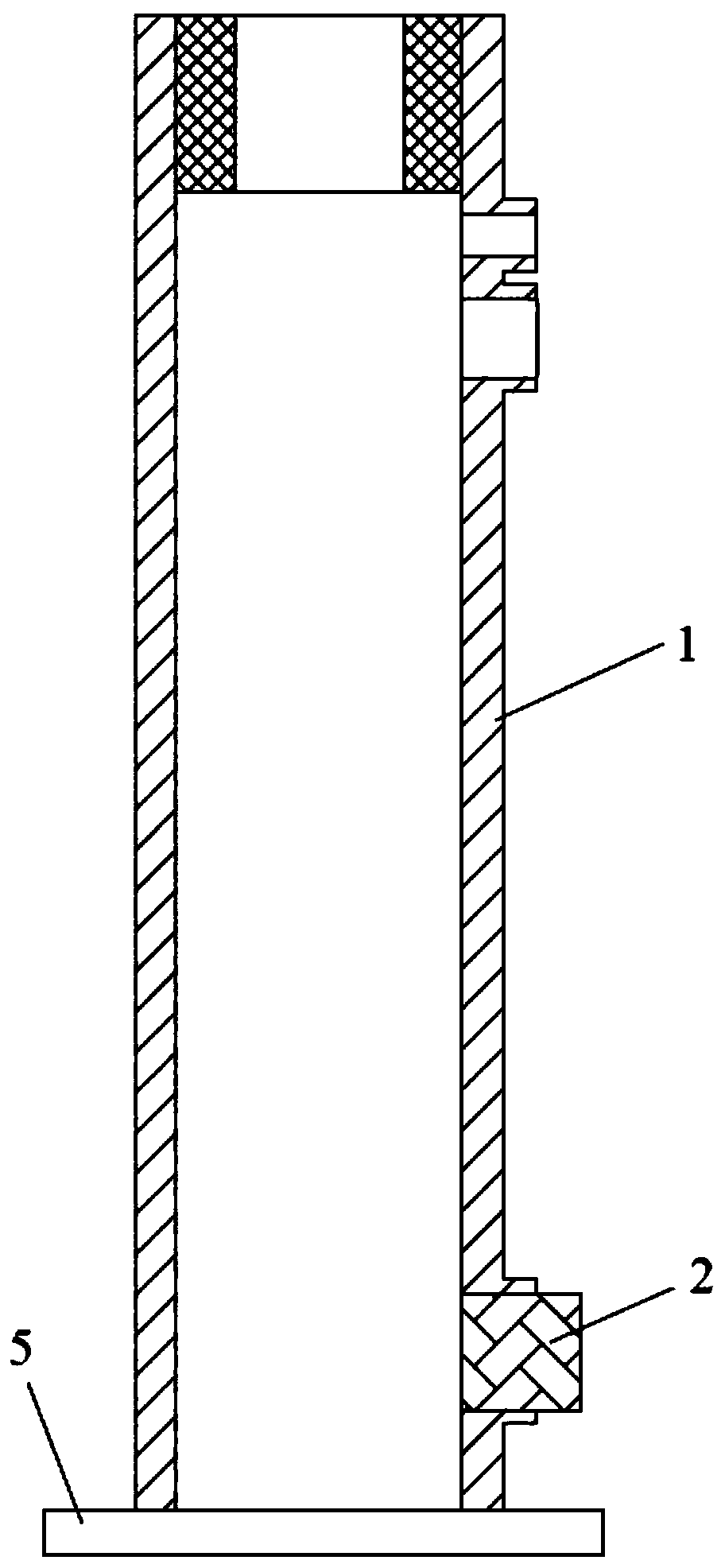

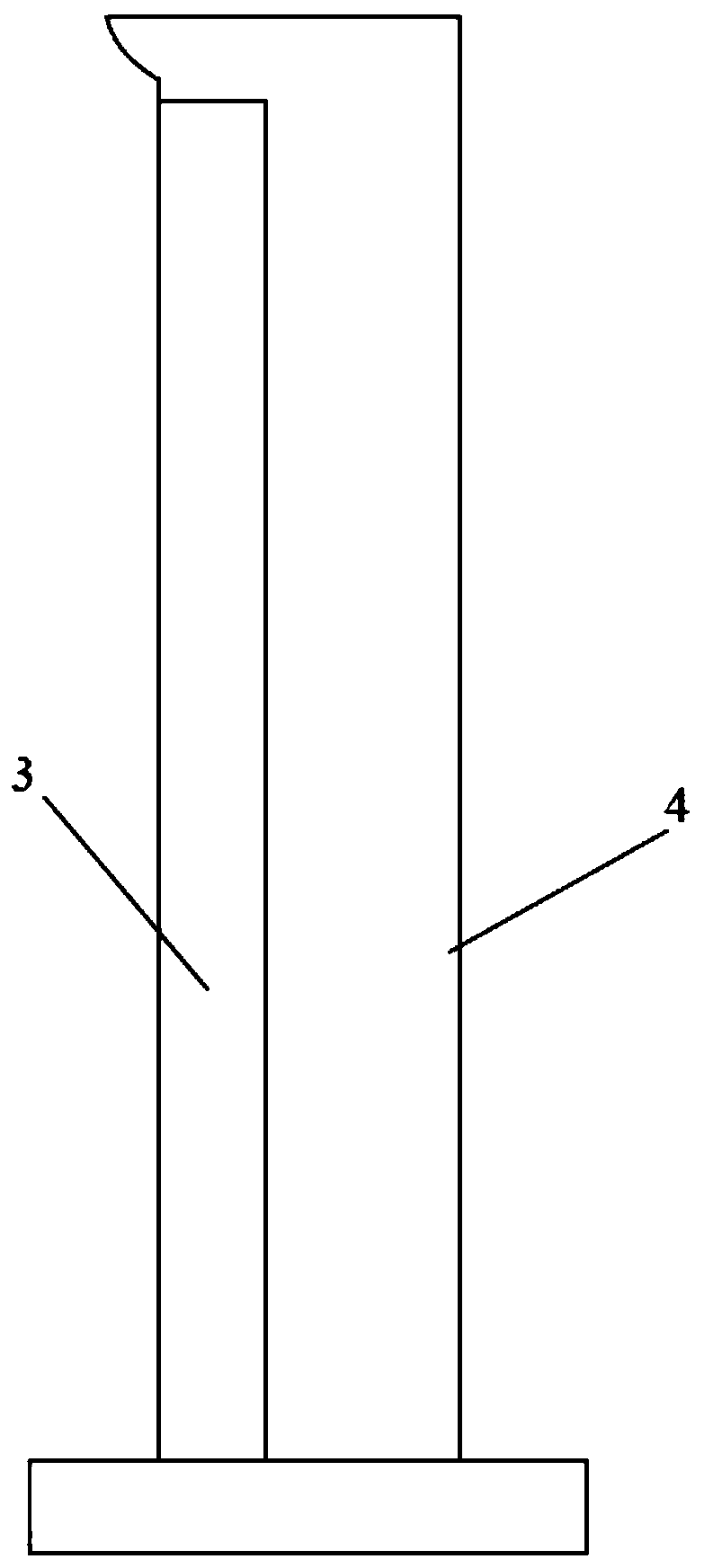

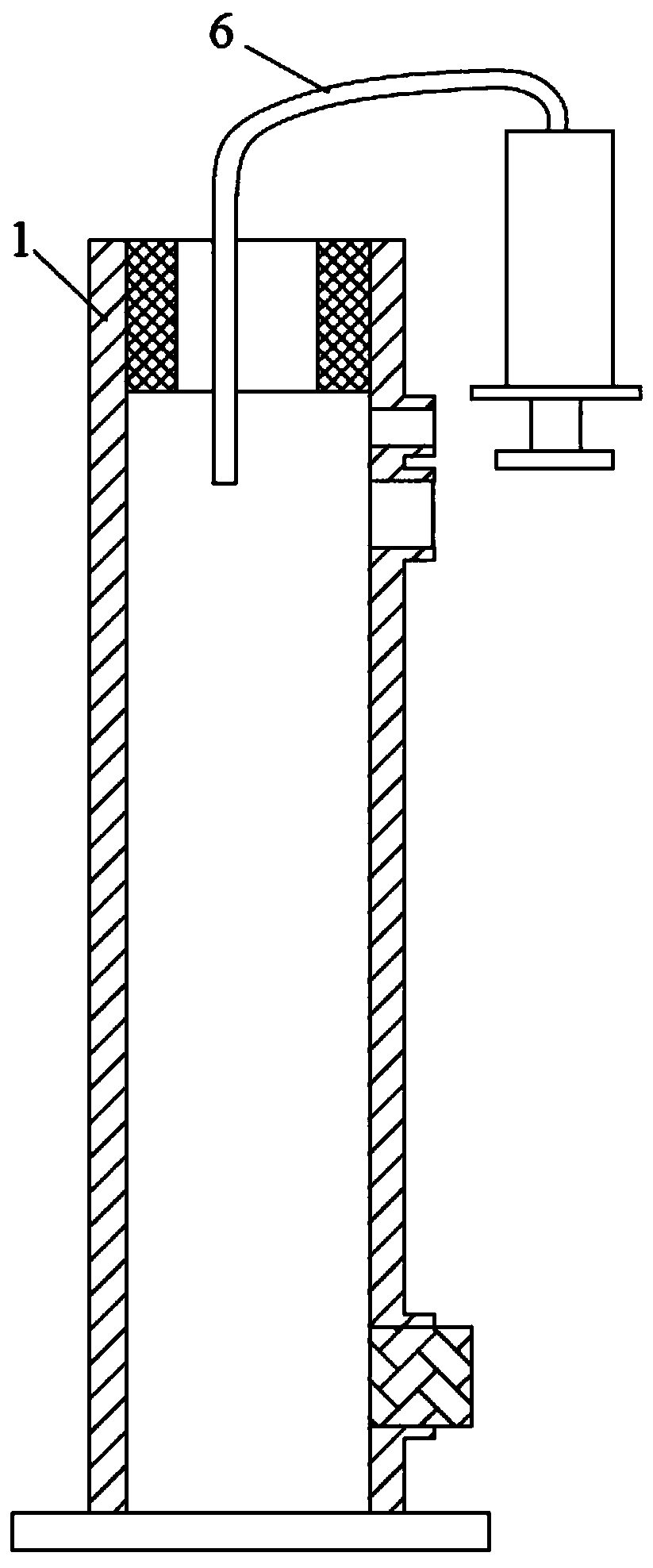

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

[0042] An embodiment of the method for on-site rapid calibration of the standard grouting amount of the steel half-grouting sleeve of the present invention includes an industrial endoscope, a syringe, a water injection hose, a measuring cylinder, a size scale tape and a rubber stopper;

[0043]The above-mentioned industrial endoscope includes a probe pipeline, and the two ends of the probe pipeline are respectively connected to the endoscope host and the endoscope probe for visualizing the inside of the semi-grouting sleeve; the above-mentioned water injection hose is connected to the injection end of the syringe to form an injection The device can inject water into the semi-grouti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com