Lotus seed thresher

A technology of thresher and lotus canopy, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve problems such as low efficiency and unfavorable automatic production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

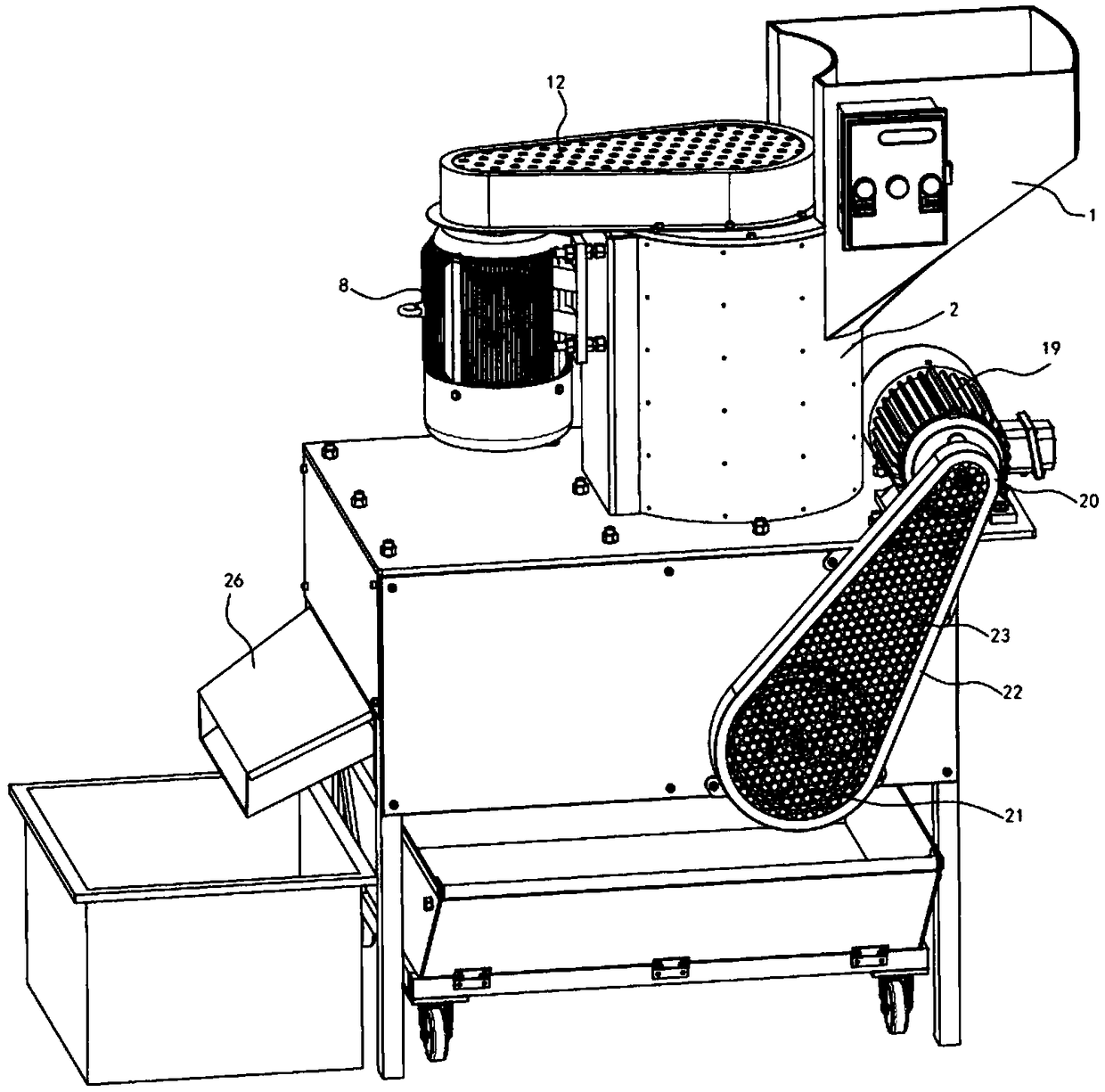

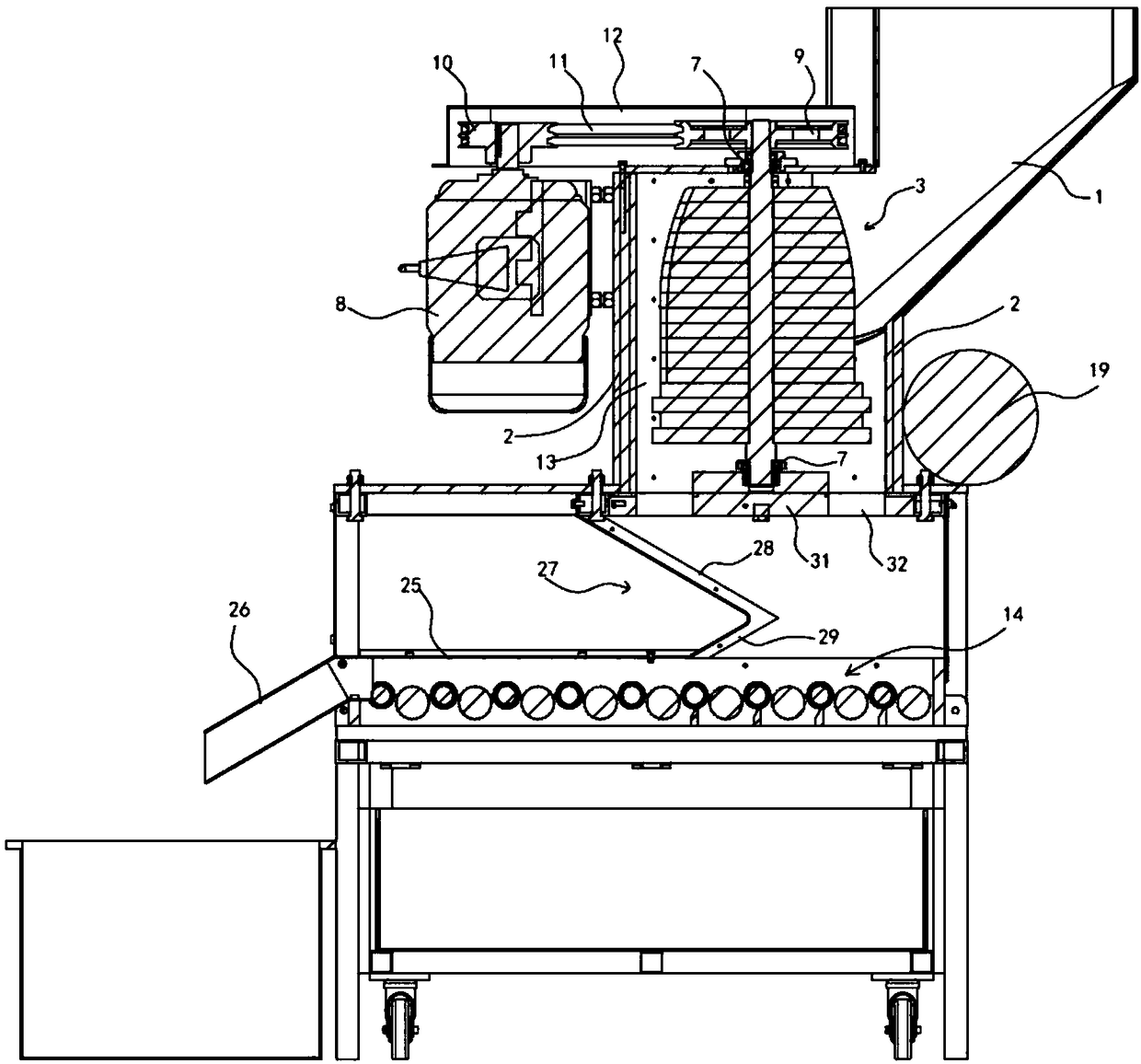

[0042] Figure 1 to Figure 4 Schematically shows a lotus thresher according to an embodiment of the present invention. Such as figure 1 and 2 As shown, a lotus pod thresher includes a feed port 1, a feed bin 2 and a lotus pod crushing unit 3.

[0043] The feeding port 1 is connected with the silo 2, and the feeding port 1 is for the lotus to enter the silo 2;

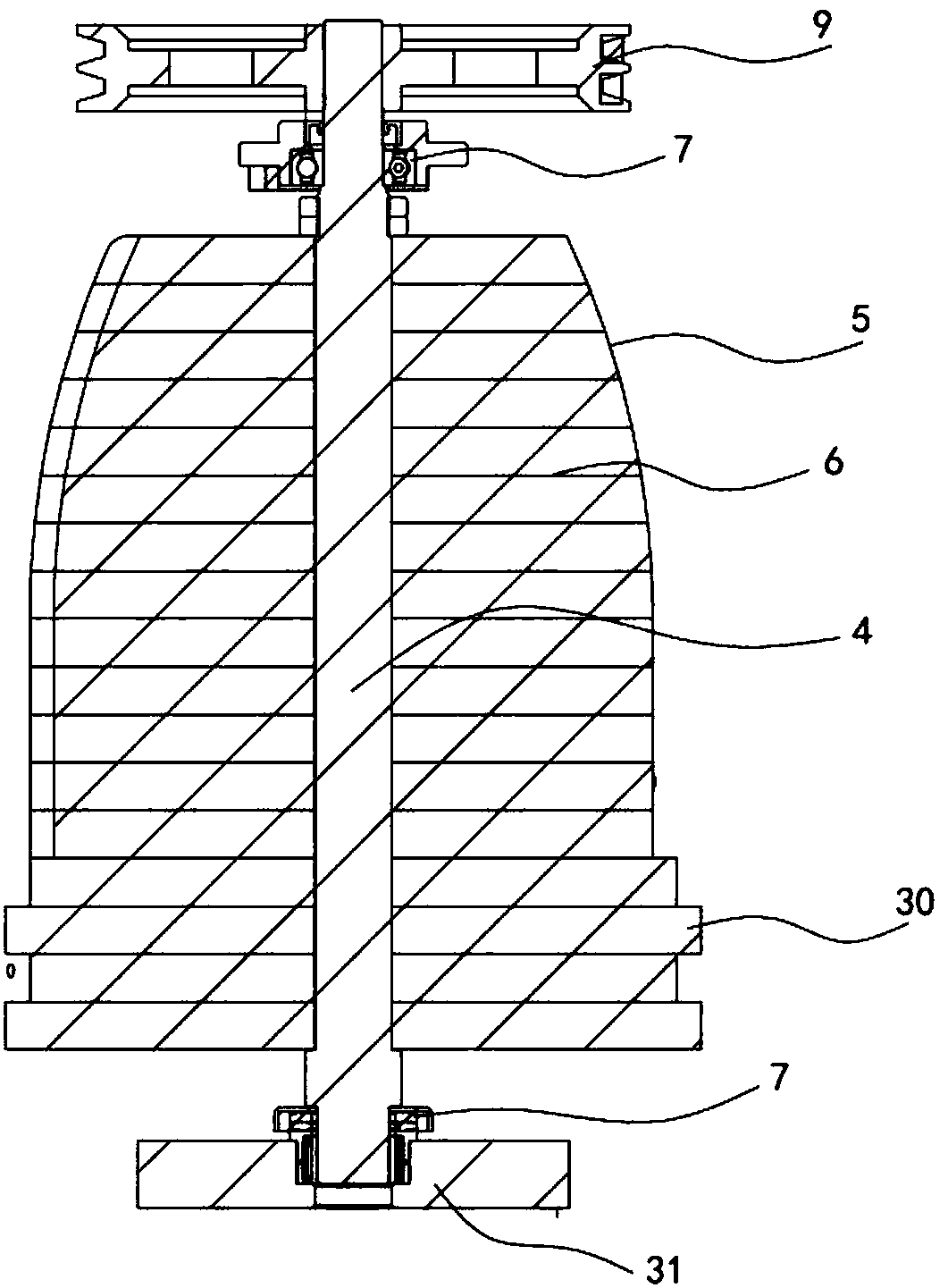

[0044] Such as image 3 As shown, the lotus pod crushing unit 3 includes a rotating shaft 4 and a crushing part 5 located on the rotating shaft 4 , and the crushing part 5 includes a plurality of bristles 6 .

[0045] The rotating shaft 4 is driven to rotate by the first motor 8, and the rotating shaft 4 drives a plurality of brush hairs 6 to rotate. Its beneficial effect is that the bin 2 can be arranged horizontally or vertically, and the rotating shaft 4 can be directly or indirectly driven by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com