Device and method for flexible die installation during laser flexible loading

A flexible loading, flexible mold technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., to achieve the effect of improving reproducibility, work efficiency, and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

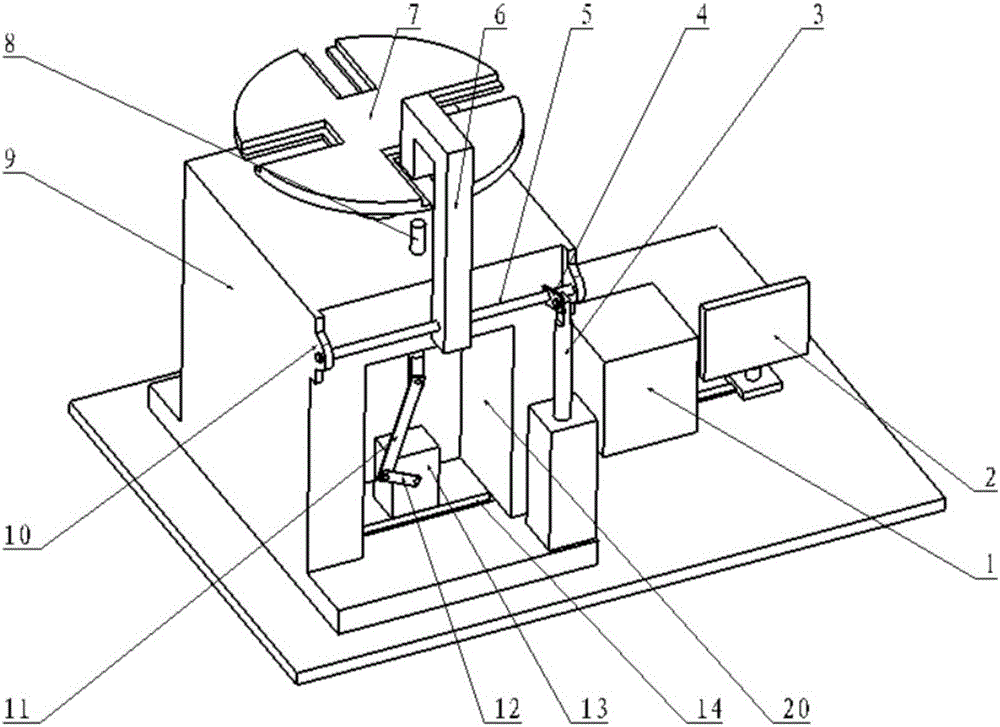

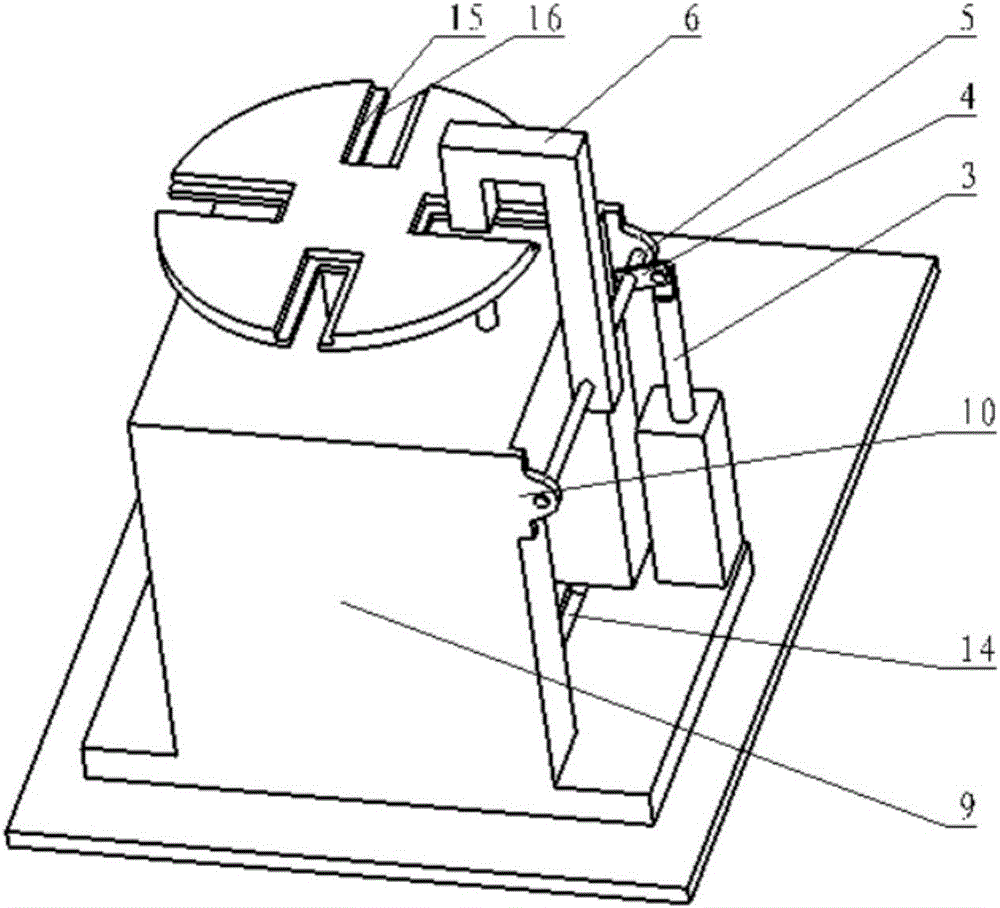

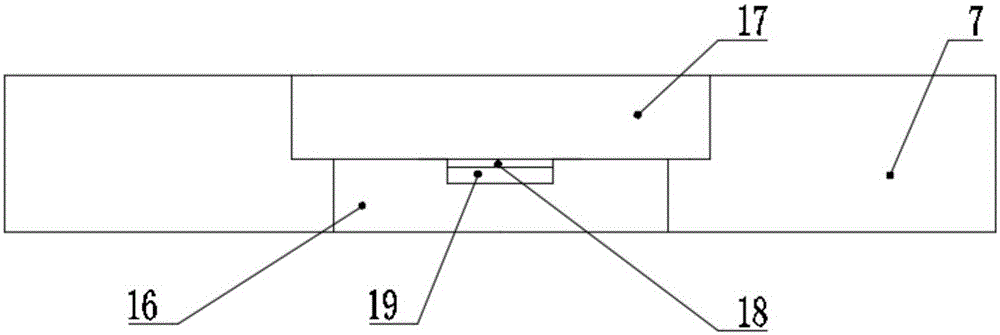

[0033] Such as figure 1 and figure 2 As shown, a device for flexible mold installation in laser flexible loading includes a flexible mold mounting bracket system, a flexible mold motion system, a constraining layer pressing system and a motion control system; the flexible mold mounting bracket system includes a flexible mold placement platform 7 and the bracket 9, the side of the flexible mold placing platform 7 is in a "convex" shape, and the flexible mold placing platform 7 is fixed at the center position of the upper surface of the support 9; the flexible mold placing platform 7 is evenly opened with 4 Two double "U" shaped grooves; each double "U" shaped groove is separated by 90°; each double "U" shaped groove is divided into a constraint layer placement groove 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com