Multi-functional double-layer beehive base plate for apis mellifera

A multi-functional, bottom plate technology, applied in beehives, beekeeping, applications, etc., can solve problems such as lowering nest temperature, crushing bees, and bee colony commotion, and achieves the effect of convenient placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

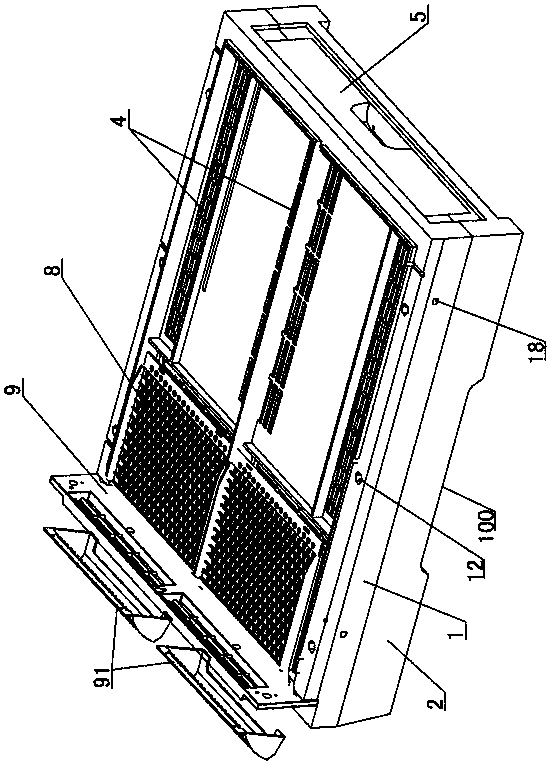

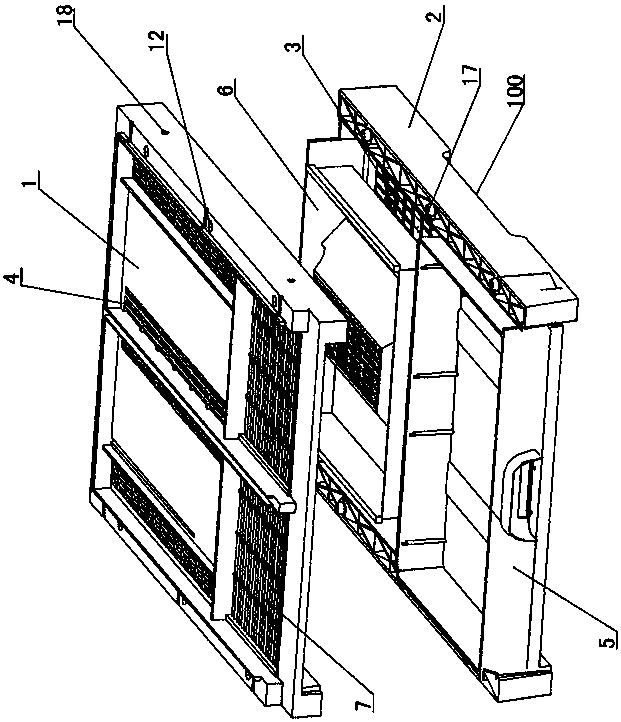

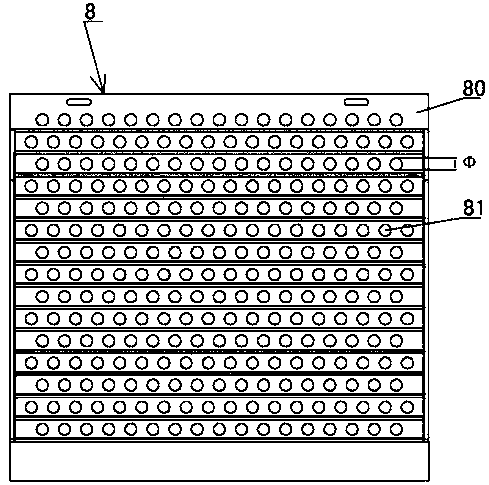

[0016] The invention relates to a multifunctional double-layer beehive bottom plate for Italian bees, such as figure 1 — Figure 9 As shown, it includes an upper base plate 1 and a lower base plate 2 arranged in double layers, a ventilation grille 3 is arranged on the lower base plate 2, an upper feeding channel 4 is arranged on the upper base plate, and a drawer-type powder receiving box 5 is arranged between the upper base plate and the lower base plate With the feeder 6, the front portion of the upper bottom plate 1 is provided with a powder filter grid 7. During powder removal, a powder remover 8 is arranged on the powder filter grid, and the powder remover 8 corresponds to the powder receiving box 5 up and down. , The powder remover 8 is obliquely placed on the powder receiving box 5, and the nest door 9 is set at the front end of the upper base plate 1, and the nest door is provided with a nest door push plate 10 and an anti-queen bee escape grille 11. The upper base pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com