Fluid heat exchange assembly and vehicle heat management system

A technology for heat exchange components and fluids, which is applied in vehicle components, component optimization, and air handling equipment. The effect of piping layout, reducing heat waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

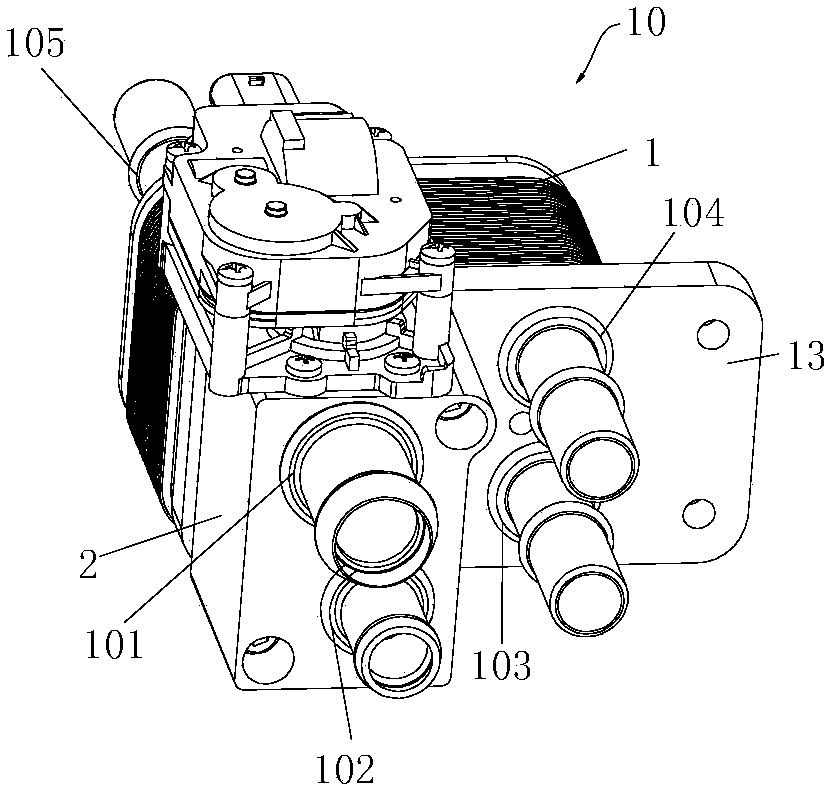

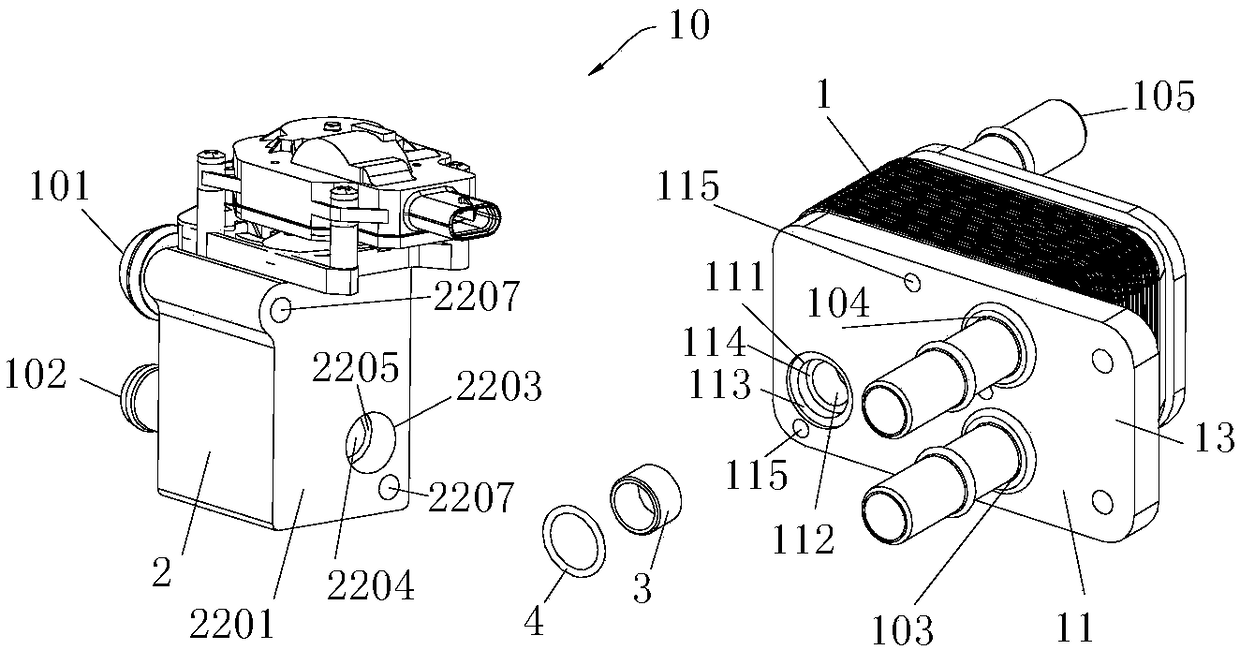

[0035] Reference figure 1 , figure 1 A schematic diagram of the fluid heat exchange assembly 10 is shown. The fluid heat exchange assembly 10 includes at least a first external interface 101, a second external interface 102, and a third external interface 103. The fluid heat exchange assembly 10 includes a fluid heat exchange module 1 and a fluid conduction Module 2, the fluid conduction module 2 is provided with a first external interface 101 and a second external interface 102, and the fluid heat exchange module 1 is provided with a third external interface 103. In this article, the external interface is located at the port of the channel of the fluid heat exchange component. In the figure, when the external interface is not visible, in order to facilitate the location of the external interface, the position of the external interface may refer to the external interface connected to the external interface. Take over.

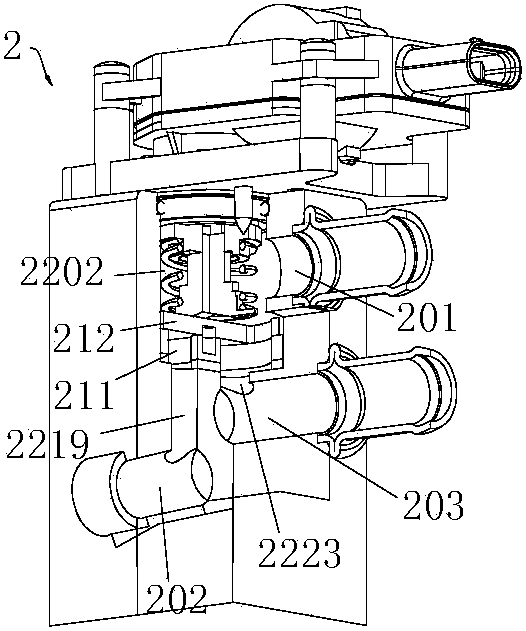

[0036] Reference image 3 The fluid conduction module 2 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com