Electric assist bicycle torque measurement device capable of detecting pedaling torque at two ends of crank shaft

A torque detection and crankshaft technology, applied in vehicle parts, transportation and packaging, rider drive, etc., can solve problems such as torque control errors of electric bicycles, the influence of pedal torque hysteresis, and sensor exposure. , to achieve the effect of simple pedal torque control, improved safety and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Regarding the technical means of our inventors, several preferred embodiments will be described in detail below in conjunction with the drawings, so as to provide an in-depth understanding and approval of the present invention.

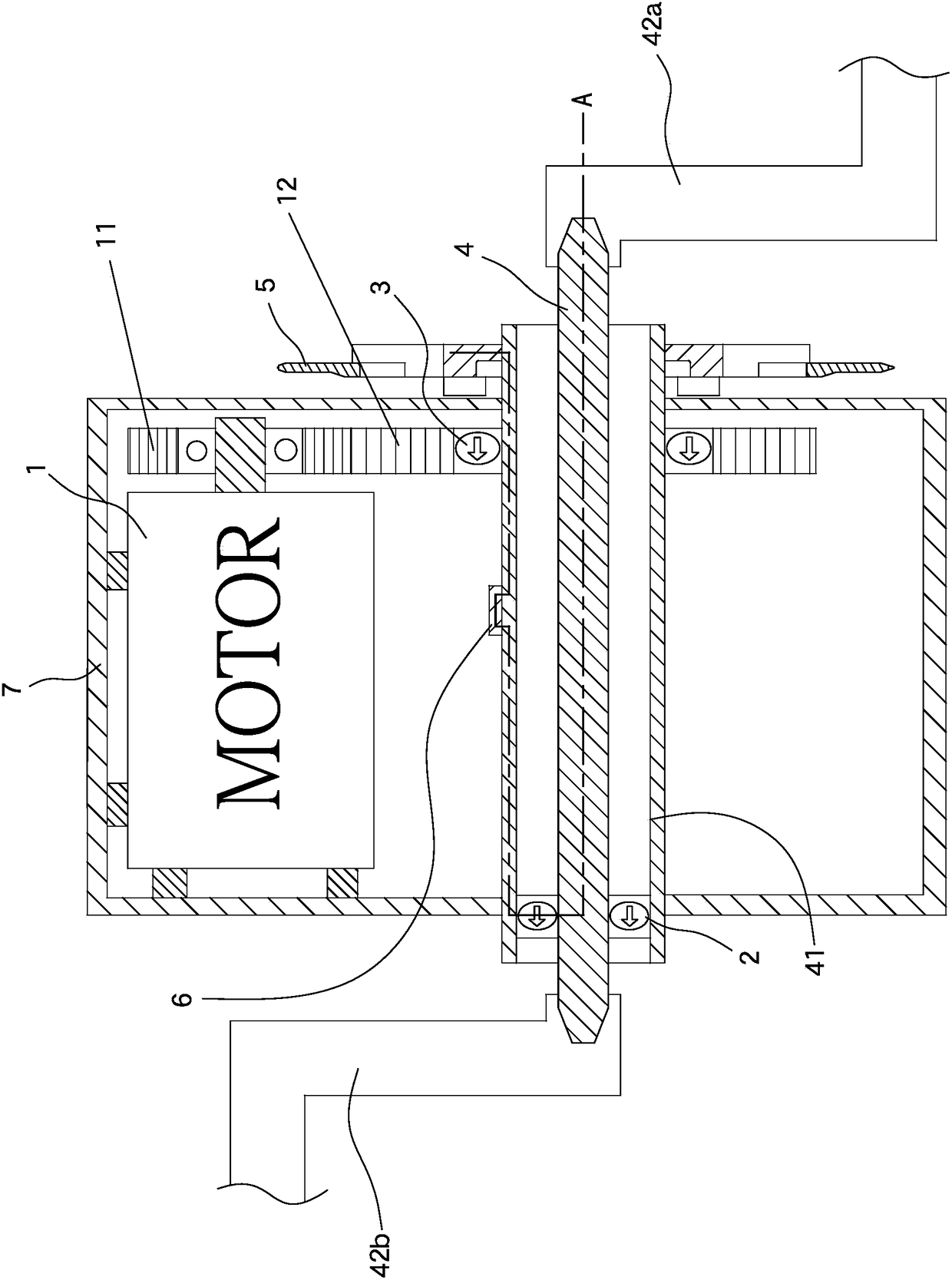

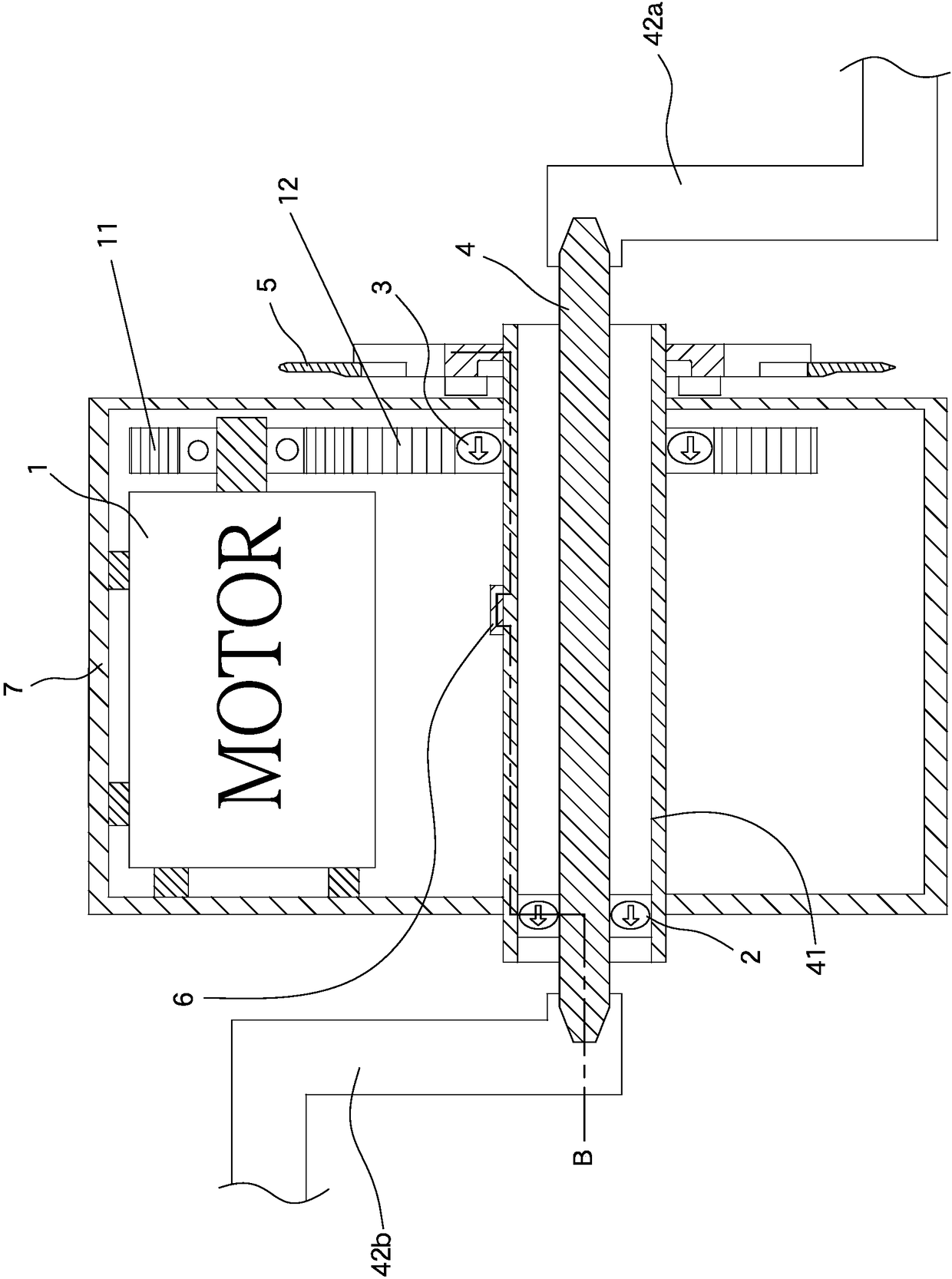

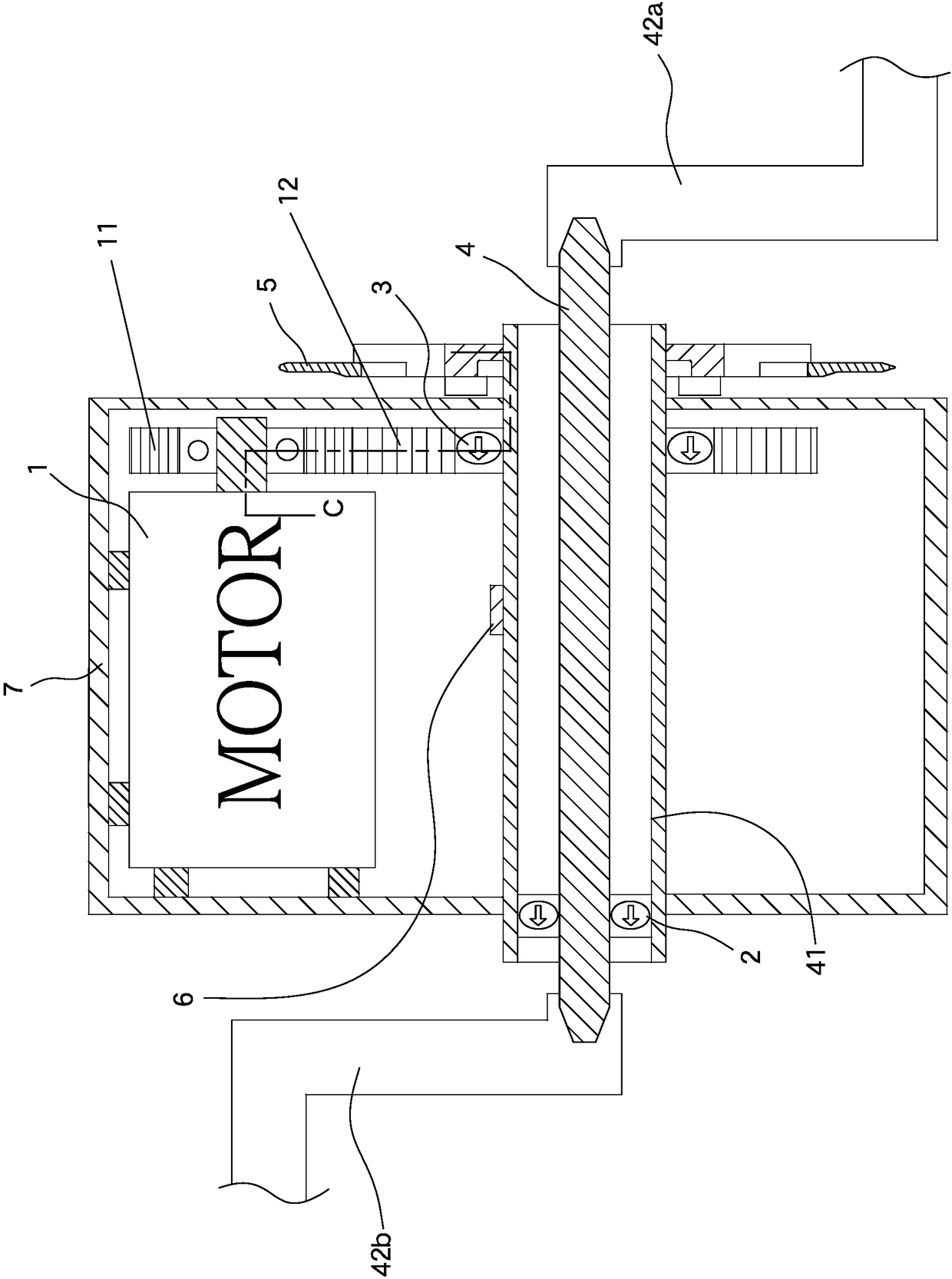

[0031] Please see first Figure 1 to Figure 3 As shown, it is the first embodiment of the present invention. The present invention is a torque detection device for an electric bicycle that can detect the pedaling torque at both ends of the crankshaft, which includes:

[0032] Define a pedaling torque and a mid-mounted motor 1, and the pedaling torque and the power provided by the mid-mounted motor 1 are respectively connected to a set of one-way gears 2 and second one-way gears 3 by means of a corresponding one-way transmission device. A hollow shaft 41 of the crankshaft 4 is then transmitted to a transmission sprocket 5 arranged on the hollow shaft 41 by means of the hollow shaft 41, wherein, the crankshaft 4 and the hollow shaft 41 are passed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com