Holding device

A technology for clamping wheels and seats, applied in conveyors, manipulators, chucks, etc., can solve the problems of easily damaged workpiece surface, weak structure of end holders, etc., and achieves the effect of compact structure, balanced strength and strong reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

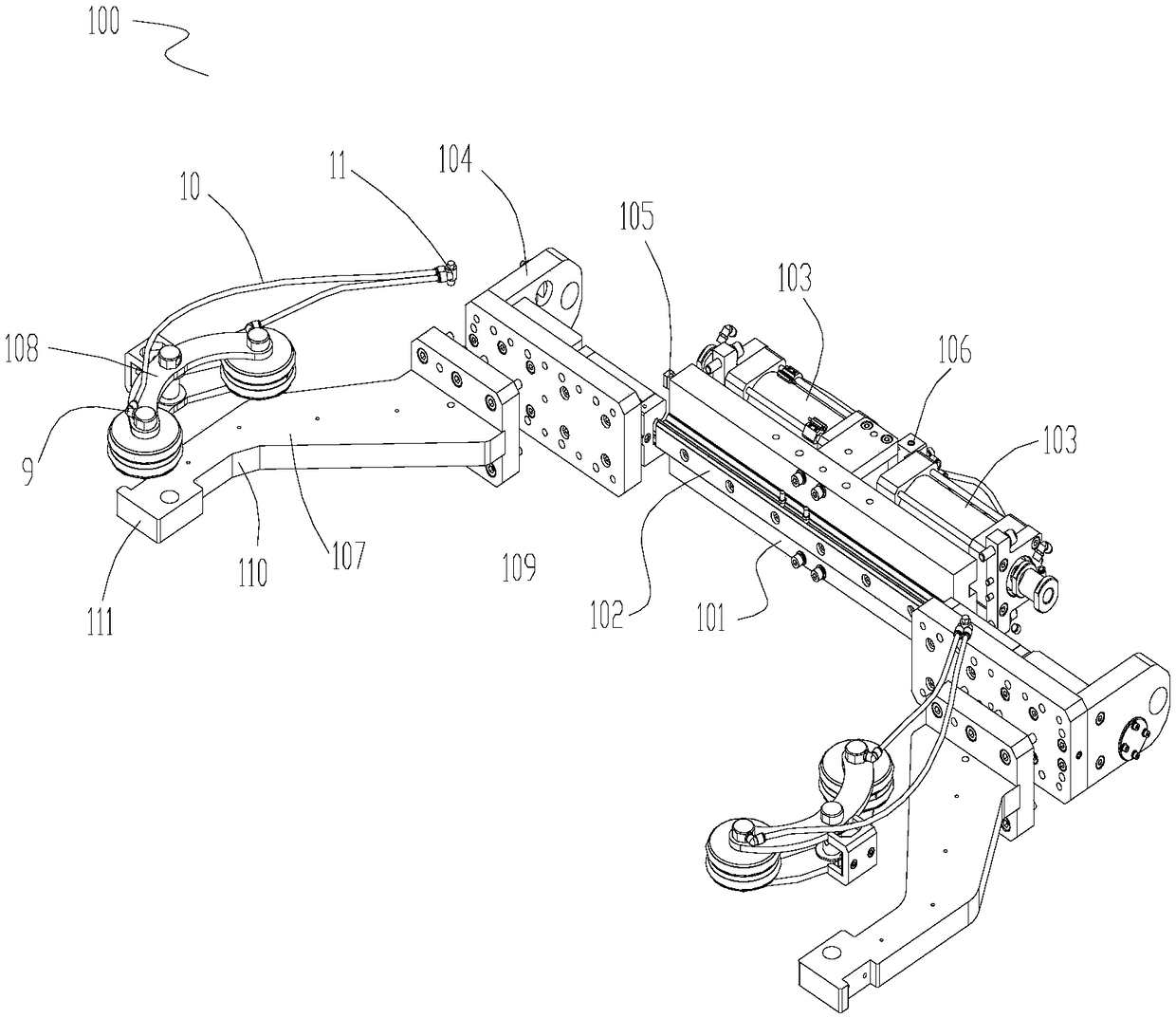

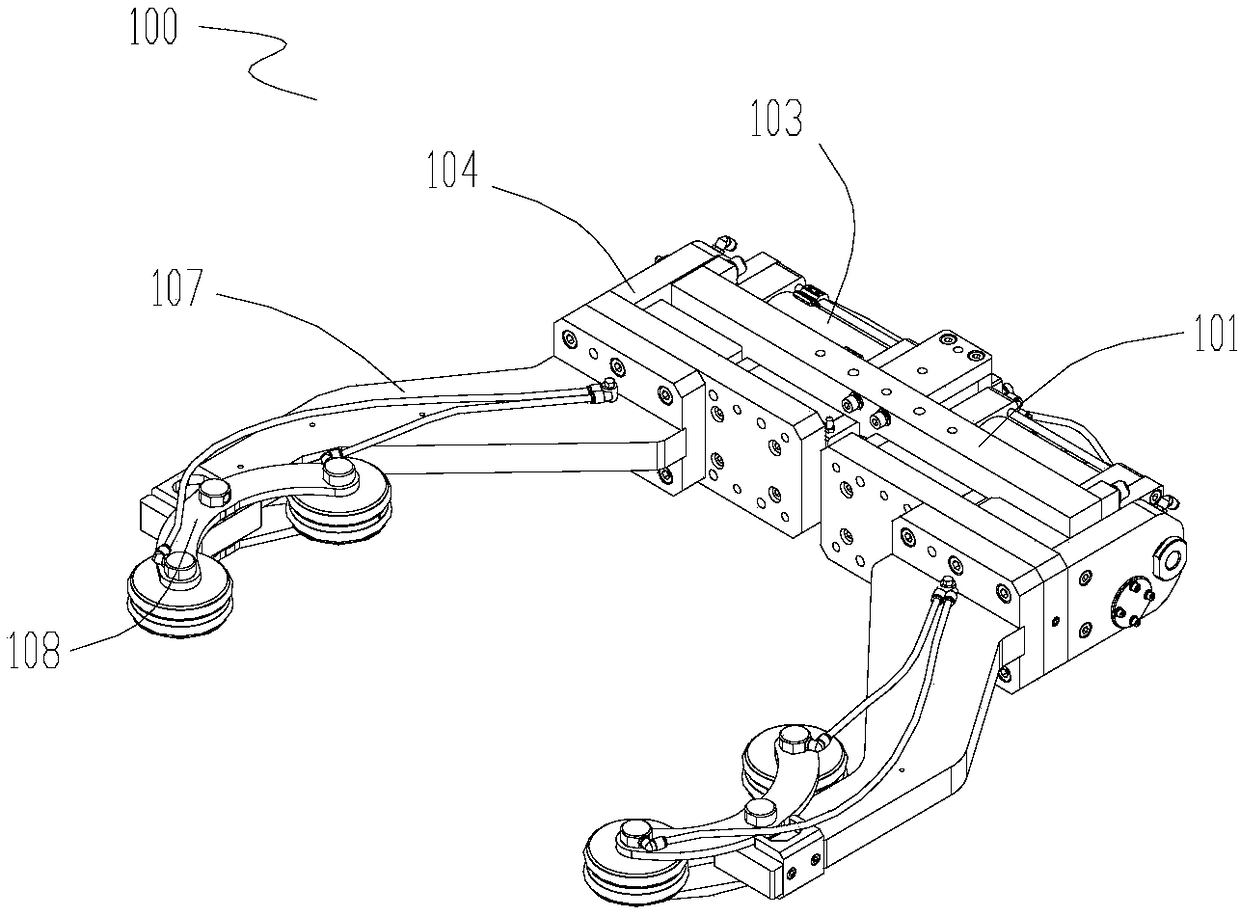

[0018] Please also refer to Figures 1 to 2 , an end holder 100, comprising a seat body 101, a slide rail 102 is provided on one side of the seat body 101, and two oppositely arranged cylinders 103 are provided on the other side.

[0019] Two slide assemblies 104 are mounted on the slide rail 102 and can move synchronously along the slide rail under the action of the cylinder 103 . The base body 101 is further provided with racks 105 fixedly connected with the two sliding assemblies 104 respectively. A valve guide assembly 106 is also arranged on the seat body 101 .

[0020] An arm assembly 107 is fixed on the sliding assembly 104 , and a clamping finger 108 is also provided at the free end of the arm assembly 107 .

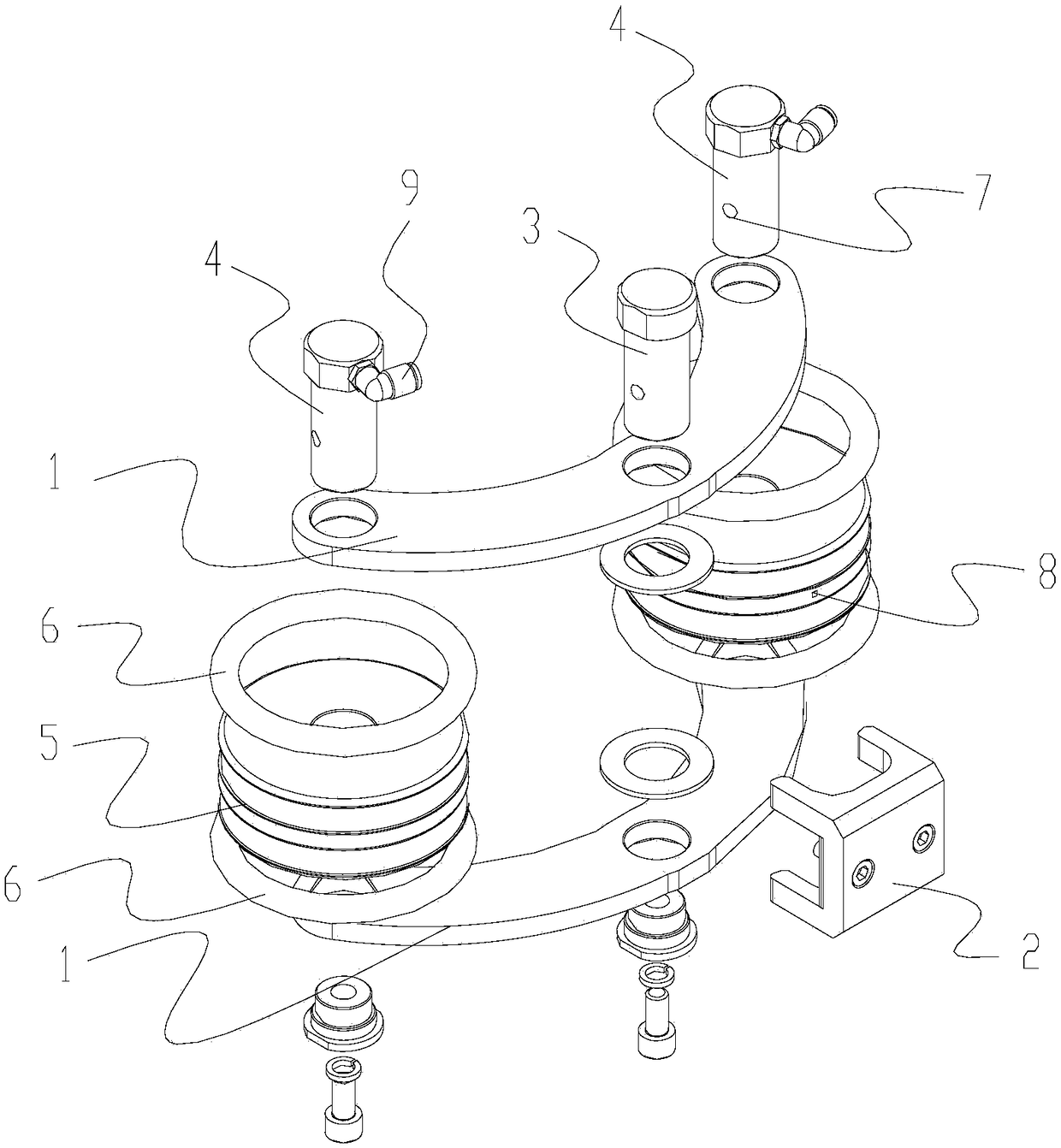

[0021] The arm assembly 107 has: a fixing portion 109 connected to the slider assembly 104 , and a middle bending portion 110 . The connecting block 2 for clamping the finger 108 is fixed on the free end 111 of the arm assembly, and one of the clamping wheels ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com