Non-woven fabric post processing reeling and unreeling system

A non-woven, unwinding and unwinding technology, used in metal processing, winding strips, sending objects, etc., can solve the problems of easy stretching and deformation, inconvenient control, etc., and achieve the effect of preventing excessive tension and deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

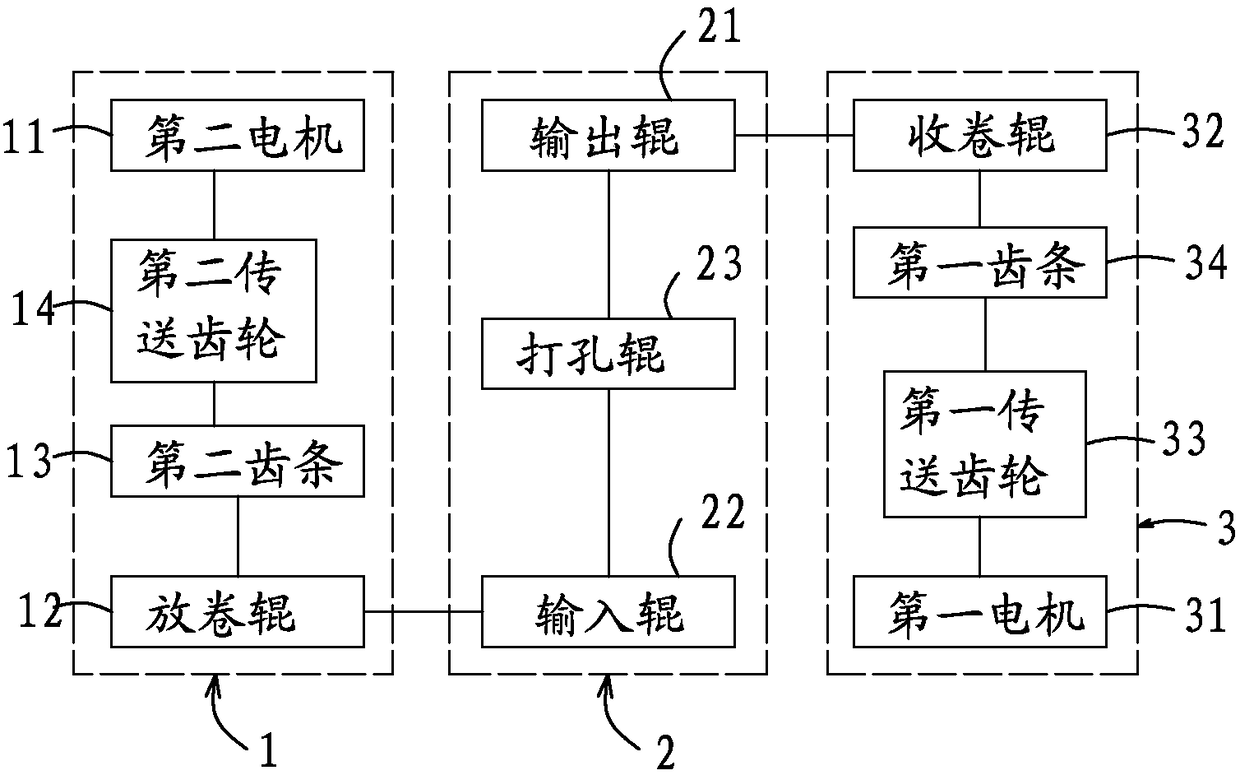

[0014] refer to figure 1 : Rewinding and unwinding system for post-processing of non-woven fabrics, including unwinding device 1, non-woven fabric punching device 2 and winding device 3, non-woven fabric punching device 2 is set between unwinding device 1 and winding device 3 , the winding device 3 includes a first motor 31 and a winding roller 32, the non-woven fabric punching device 2 includes an output roller 21, the winding roller 32 cooperates with the output roller 21, and the first motor 31 is connected with the winding roller 32, The first motor 31 can drive the winding roller 32 to move.

[0015] In actual use, the unwinding device 1, the non-woven fabric punching device 2 and the winding device 3 can all be installed on the same frame, and each roller can rotate on the frame.

[0016] The winding device 3 also includes a first transmission gear 33...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com