Steel lined anti-corrosion pipeline

A steel lining and pipeline technology, applied in the direction of pipe components, pipes/pipe joints/fittings, coatings, etc., can solve the problems of internal joints that have not been completely solved and hinder the application of high-efficiency coatings, and achieve convenient interspersed connections, Avoid exposure to corrosion and facilitate fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

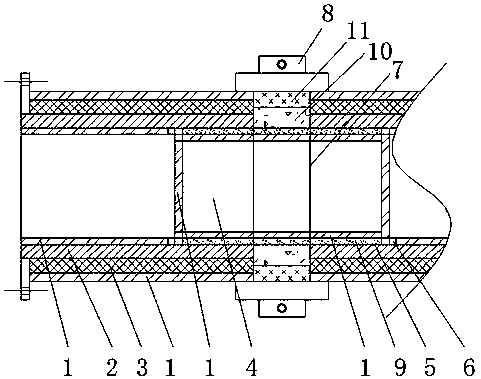

[0017] Such as figure 1 As shown, a steel-lined anti-corrosion pipeline of the present invention comprises more than two inner pipelines 2 with an anti-corrosion layer 1 on the inner surface, a steel-lined outer tube 3 outside the inner pipeline 2, and an anti-corrosion layer outside the steel-lined outer tube 3 1. A connecting pipe 4 is connected between the inner pipes 2 at adjacent ends. The inner wall of the inner pipe 2 is provided with a limiting passage 5 for the connecting pipe 4 to pass through. The end of the restricting passage 5 is provided with a limiting step 6. The adjacent inner pipe 2 is provided with a fixed ring 7 covering the connecting pipe 4, and the fixed ring 7 is provided with a fastening bracket 8 that is fastened with each other.

[0018] According to the above technical solution, the technical effect achieved is: the inner pipe 2 is provided with a limiting channel 5 and a limiting step 6, which not only facilitates the interpenetrating connection o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com