Winding machine for processing motor internal stator made from square and flat wires and working principle of winding machine

A technology of inner stator and processing side, applied in the field of winding machine, can solve the problems of high labor cost, low production efficiency, poor winding quality, etc., and achieve the effect of automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The following descriptions are only preferred embodiments of the present invention, and do not limit the protection scope of the present invention. The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

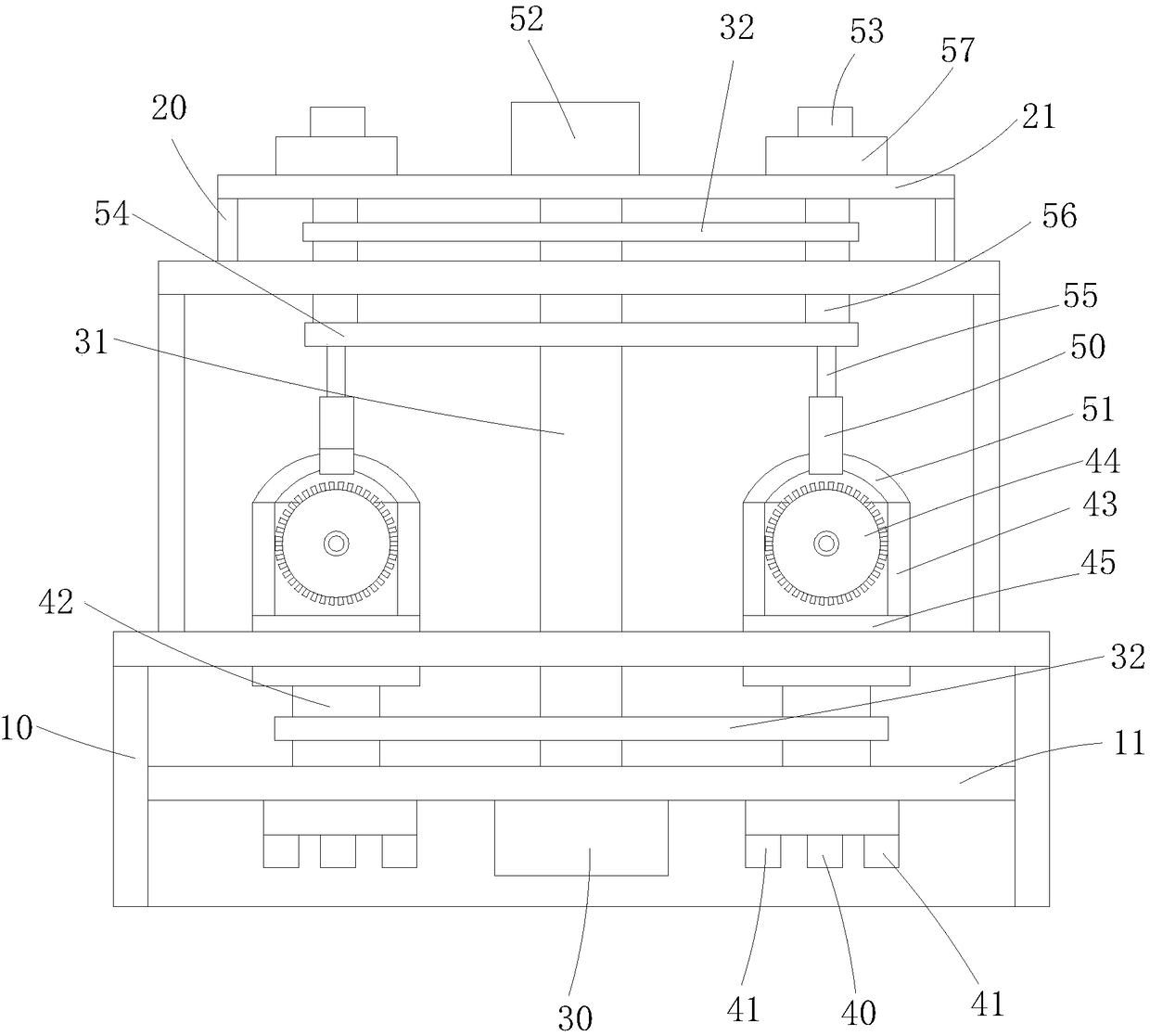

[0010] Examples, see figure 1 Shown: a winding machine for processing the inner stator of a square flat wire motor, which includes a lower base 10, an upper base 20, a PLC control box, a main servo motor 30, a driving shaft 31, a motor inner stator rotating device and a square flat The wire winding device has a lower fixed plate 11 in the lower base 10, the main servo motor 30 is fixedly arranged in the lower fixed plate 11, the active rotating shaft 31 is connected with the main servo motor 30 and it is respectively connected with the stator rotating device and the square in the motor through the belt 32. The flat wire winding device is connected; like this when the main servo motor 30 works, it can drive t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com