Air inlet and outlet structure of food processor

A food cooking machine, the technology of air in and out, applied in the direction of home appliances, applications, kitchen utensils, etc., can solve the problems of unstable placement of the machine, affecting the appearance of the machine, poor heat dissipation effect, etc., to improve the heat dissipation effect, the product appearance is beautiful, reduce area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

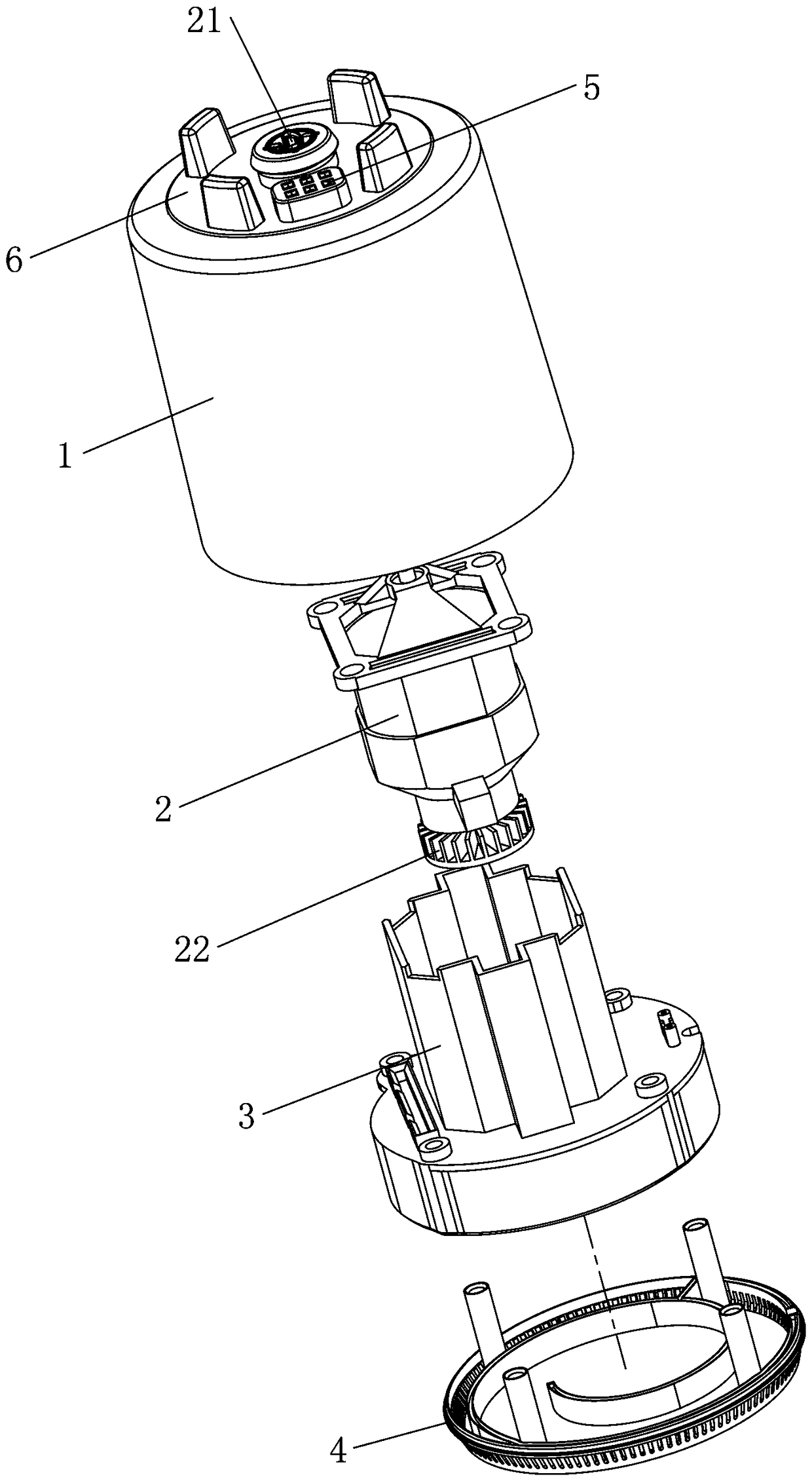

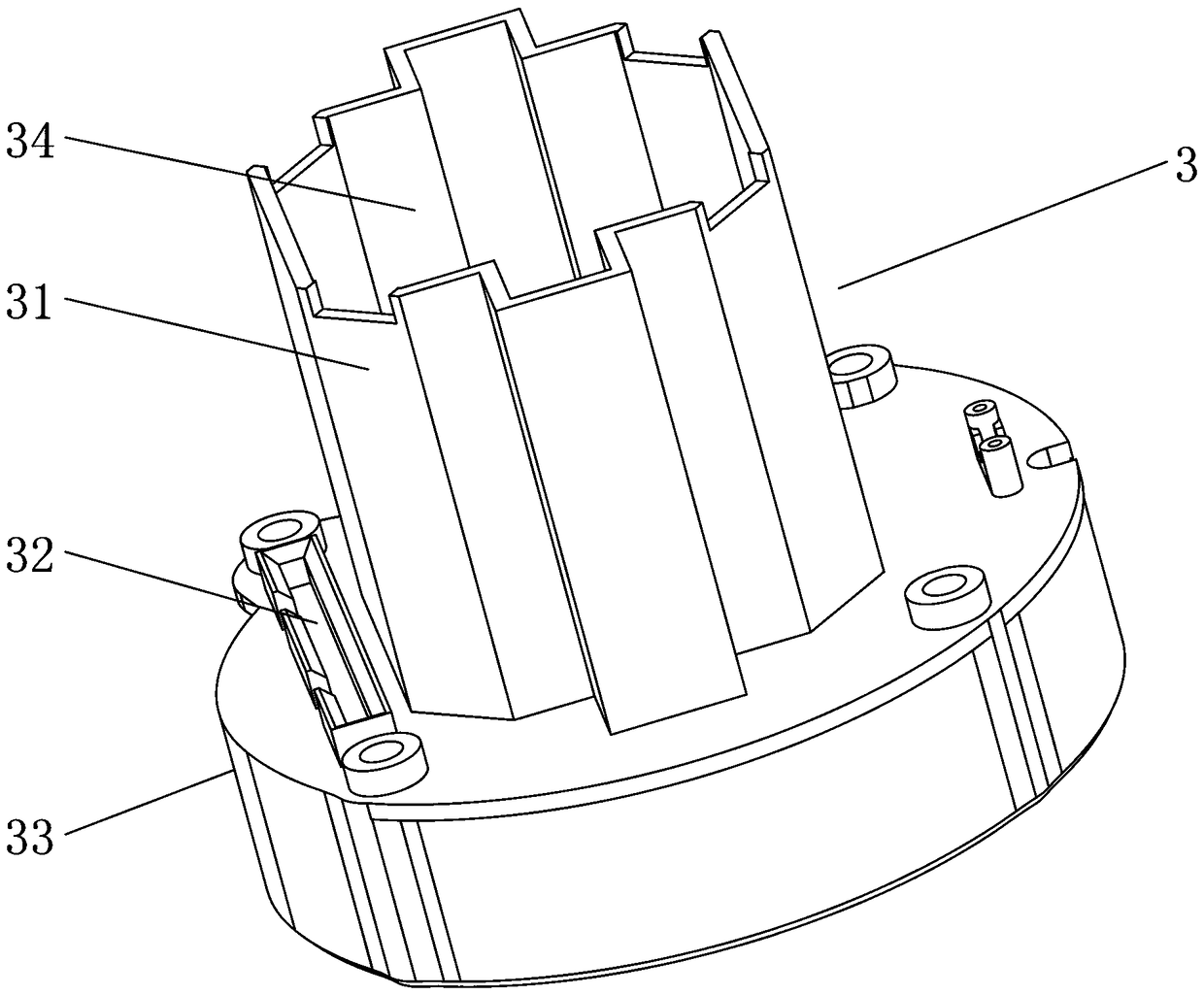

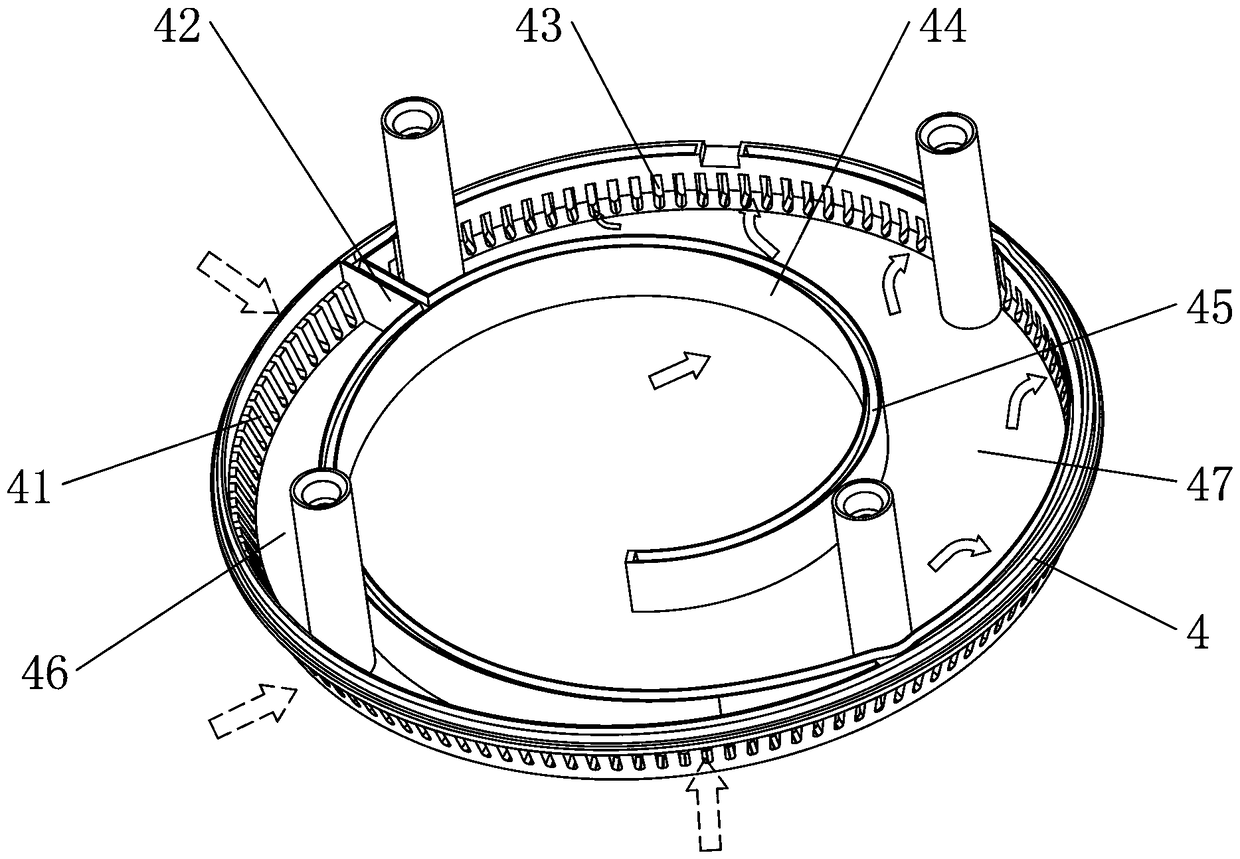

[0032] see Figure 1 to Figure 7 As shown, a food cooking machine air inlet and outlet structure includes a main engine assembly, the main engine assembly includes a shell assembly and a motor 2, the outer top of the shell assembly is provided with a first transmission joint 21, the motor 2 is arranged in the shell assembly, and is connected to the second A transmission joint 21 is transmission connected, and the motor 2 is also transmission connected with a fan 22. The housing assembly is provided with an air duct, the motor 2 and the fan 22 are arranged in the air duct, and the air duct is provided with a mutually connected air inlet cavity 11 and an air outlet Cavity 35; the outer periphery of the lower part of the shell assembly is provided with an air inlet 41 and an air outlet 43, the air inlet 41 communicates with the air inlet chamber 11, and the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com