Easy-to-move agricultural feed mixing device

A mixing device and feed technology, which is applied in the field of agriculture, can solve the problems of occasional misreading and misremembering, scattered manual batching processes, and non-centralized production processes, etc., and achieves simple structure, reduced maintenance probability, and convenient movement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

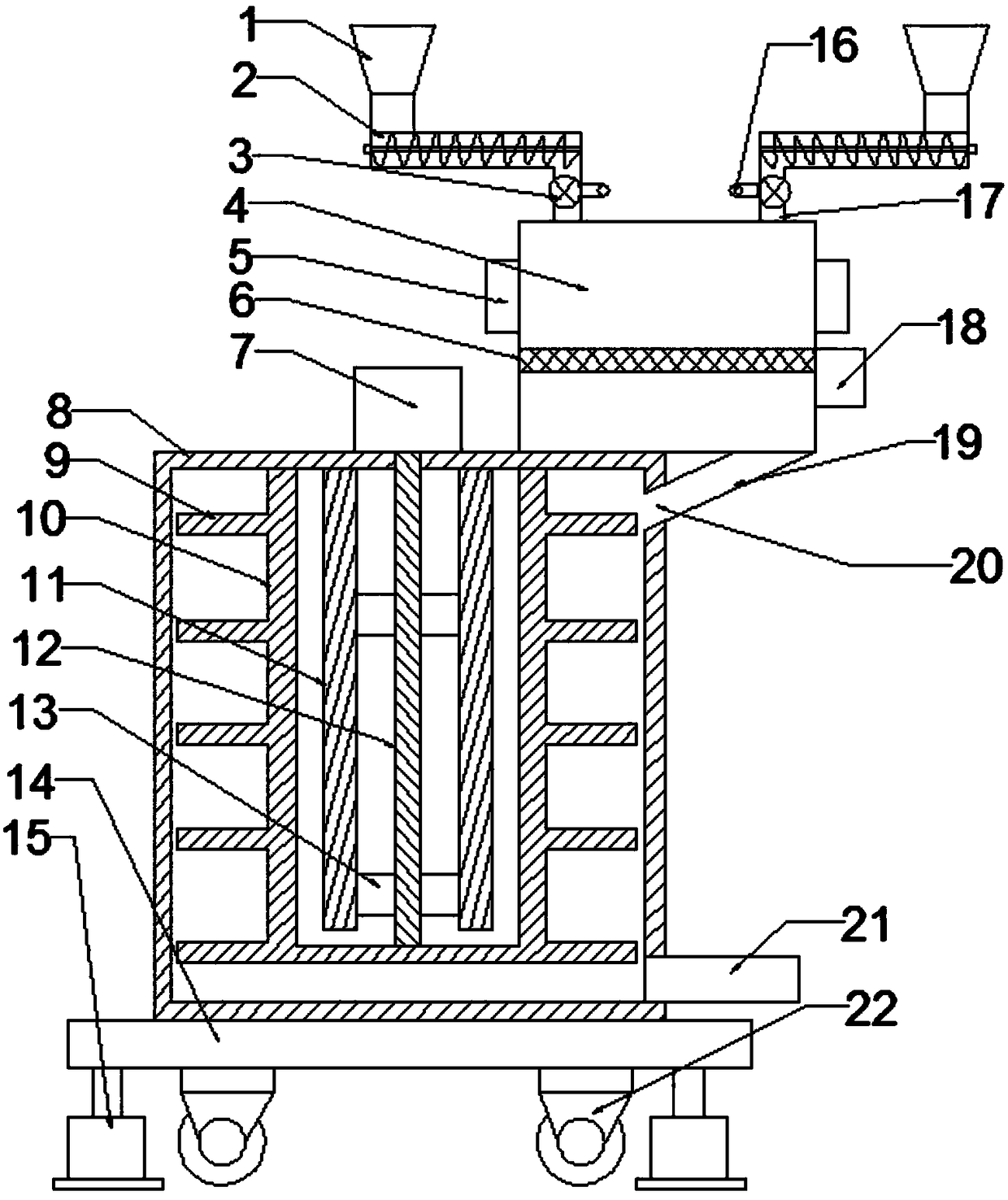

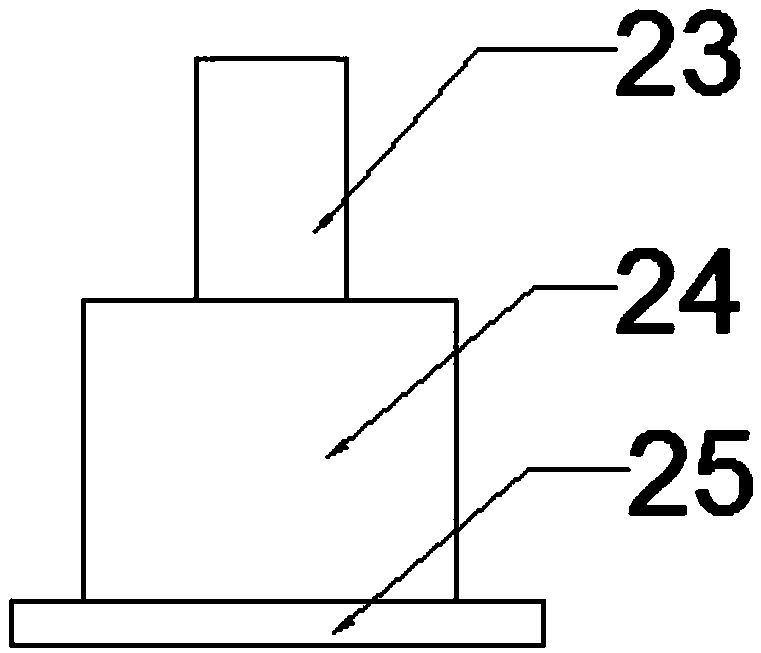

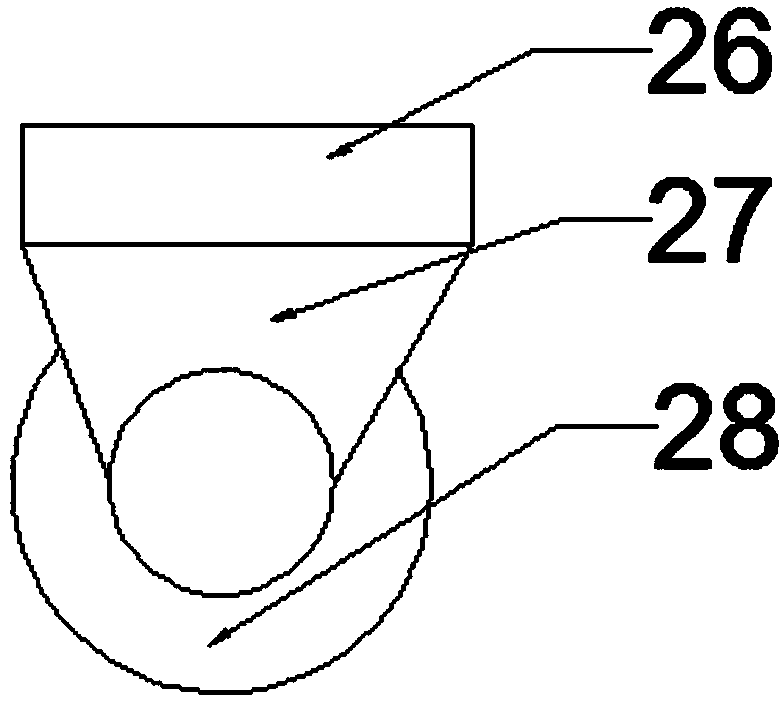

[0016] see Figure 1-3 , an agricultural feed mixing device that is easy to move, including a mixing device and a feeding device; the mixing device includes a motor 7, a casing 8, a stirring blade 9, an anti-leakage cylinder 10, a fixed cylinder 11, a main shaft 12, a bearing 13, and a base 14 , support device 15, feed port 20, discharge port 21, roller device 22, hydraulic rod 23, hydraulic device 24, anchor 25, shock absorber 26, wheel support 27 and roller 28; The bottom surface of the base 14 is four Each angle is provided with supporting device 15, and supporting device 15 comprises hydraulic rod 23, hydraulic device 24 and foundation pin 25; Described hydraulic device 24 is connected with base 14 through hydraulic rod 23; Below; the roller device 22 is fixedly arranged on the inner side of the lower end surface of the base 14, and the roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com