Omnibearing 360 degree robot assembling tool

A technology for assembling tooling and robots, used in auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve problems such as inability to turn over and horizontal rotation, affecting welding efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

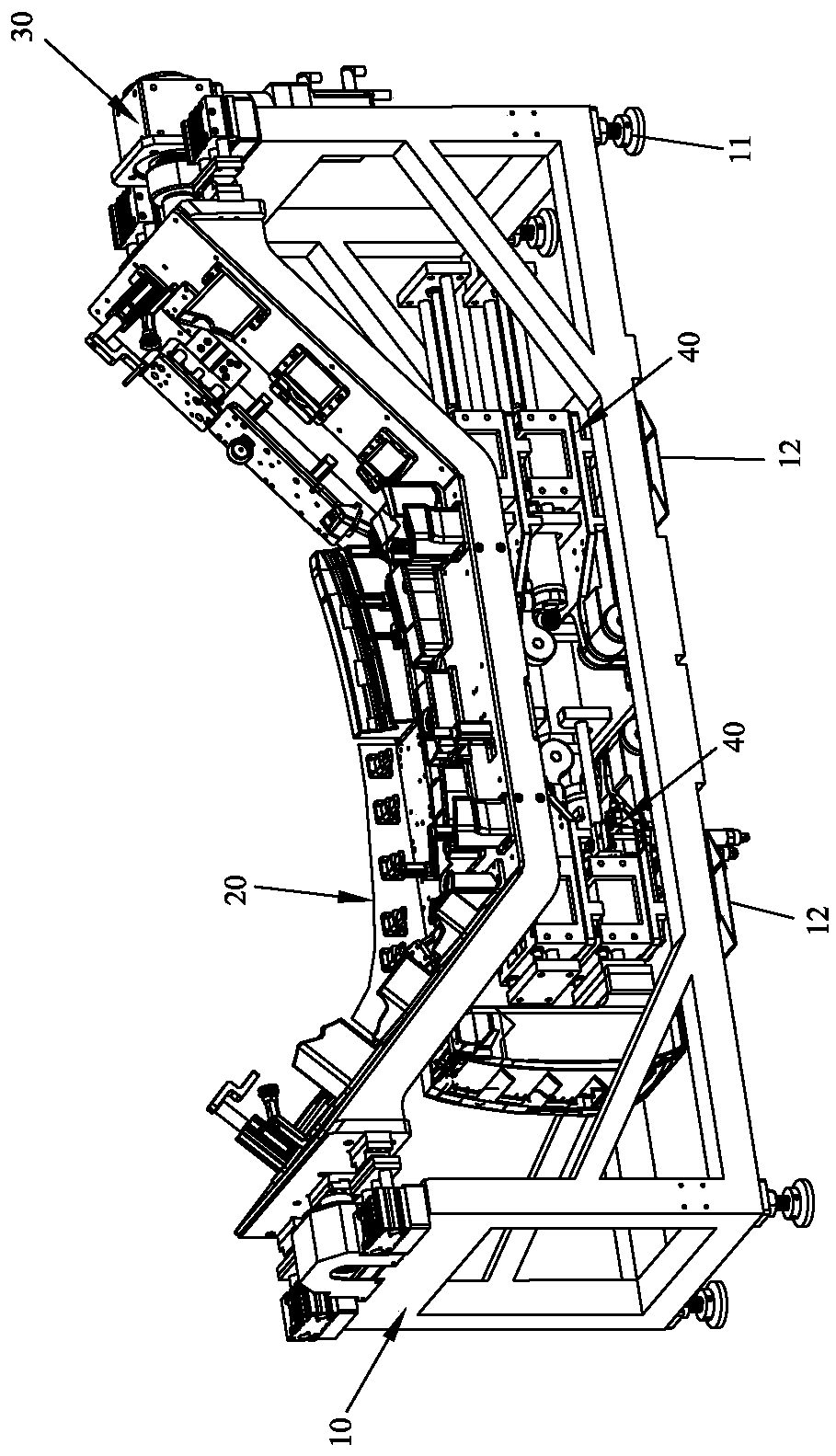

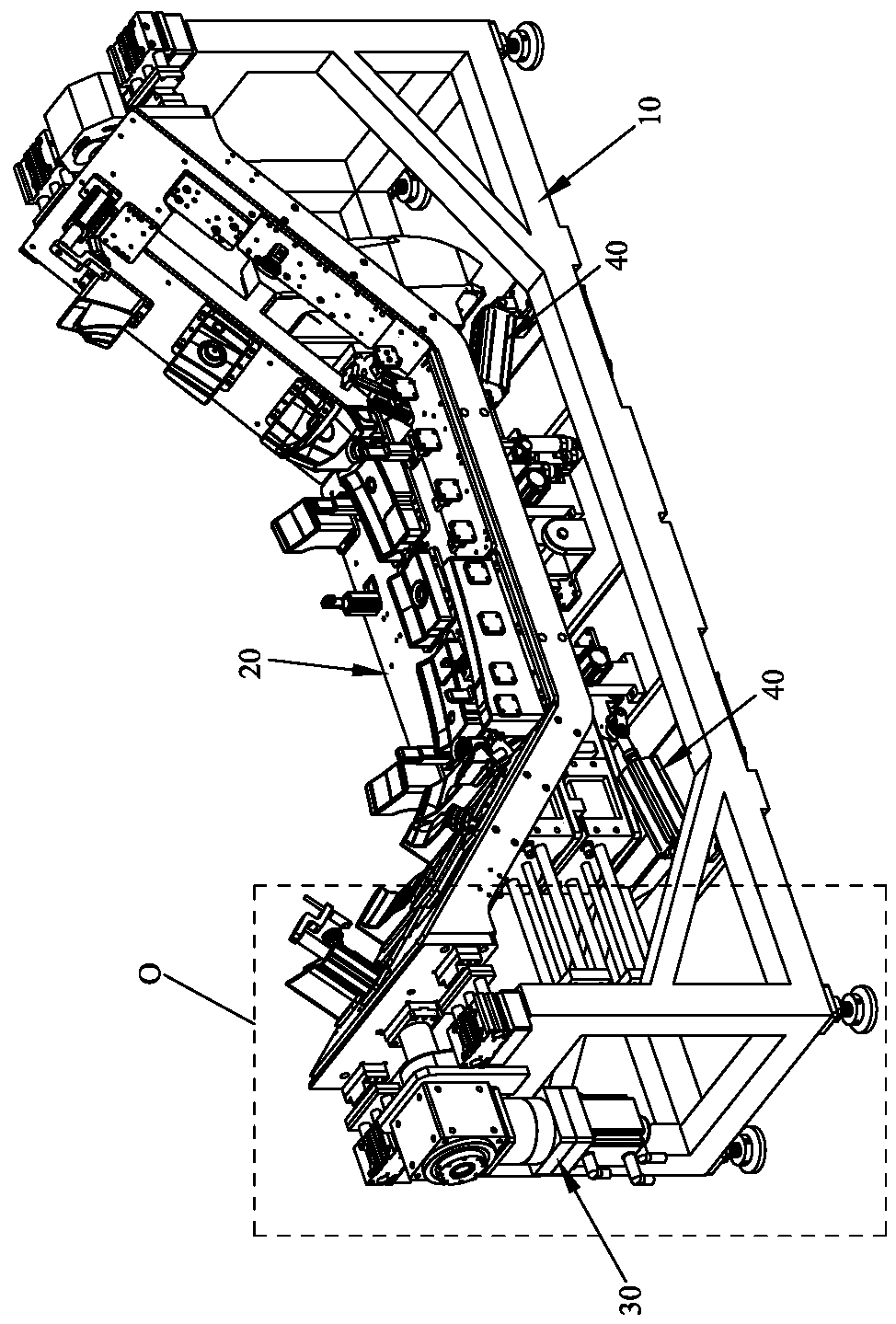

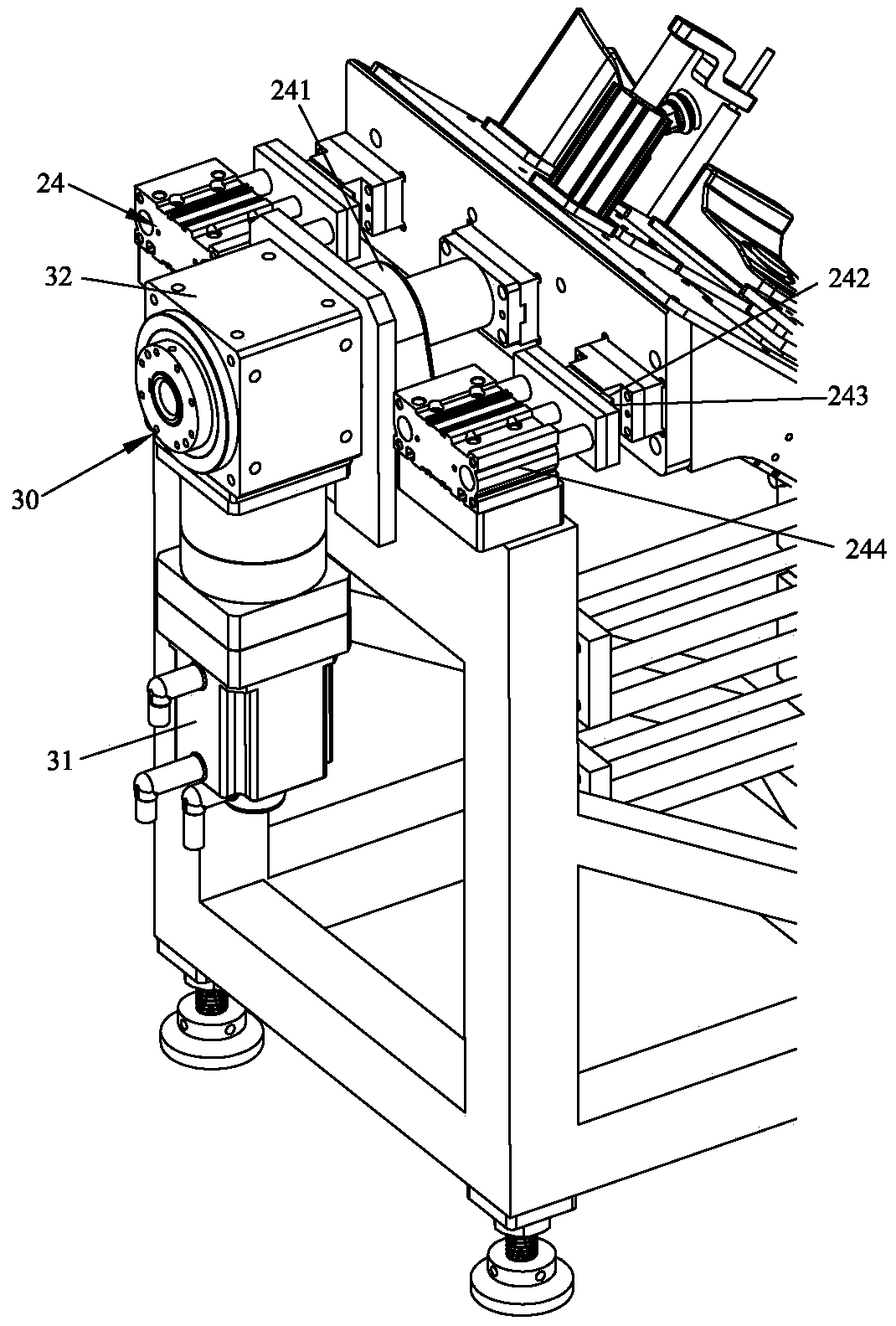

[0056] Please refer to Figure 1 to Figure 11 As shown, it shows the specific structure of the preferred embodiment of the present invention, which is an all-round 360° robot assembly tool, including a machine base 10, a membrane turning mechanism 20, a turning driving mechanism 30, and a turning support mechanism 40, Each mechanism is installed on the machine base 10, and the overturning drive mechanism 30 drives the film overturning mechanism 20 to rotate 360° to realize the front and back assembly and welding of the product (such as the front bumper of a car). When the film overturning mechanism 20 turns over to 180° , the front and back of the product can be switched, and the product can be supported by the overturning support mechanism 40 so that it will not fall from the membrane overturning mechanism 20. Through this design, the two sets of assembly work on the front and back of the product are combined in one set of tooling, which saves the space occupied by the equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com