Compact hole-forming end executer for shared guide rails of electric spindle and pressure foot

A technology of end effectors and shared guide rails, which is applied in the direction of manufacturing tools, manipulators, chucks, etc., to achieve the effects of compact design, reduced downtime preparation time, and improved hole-making efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

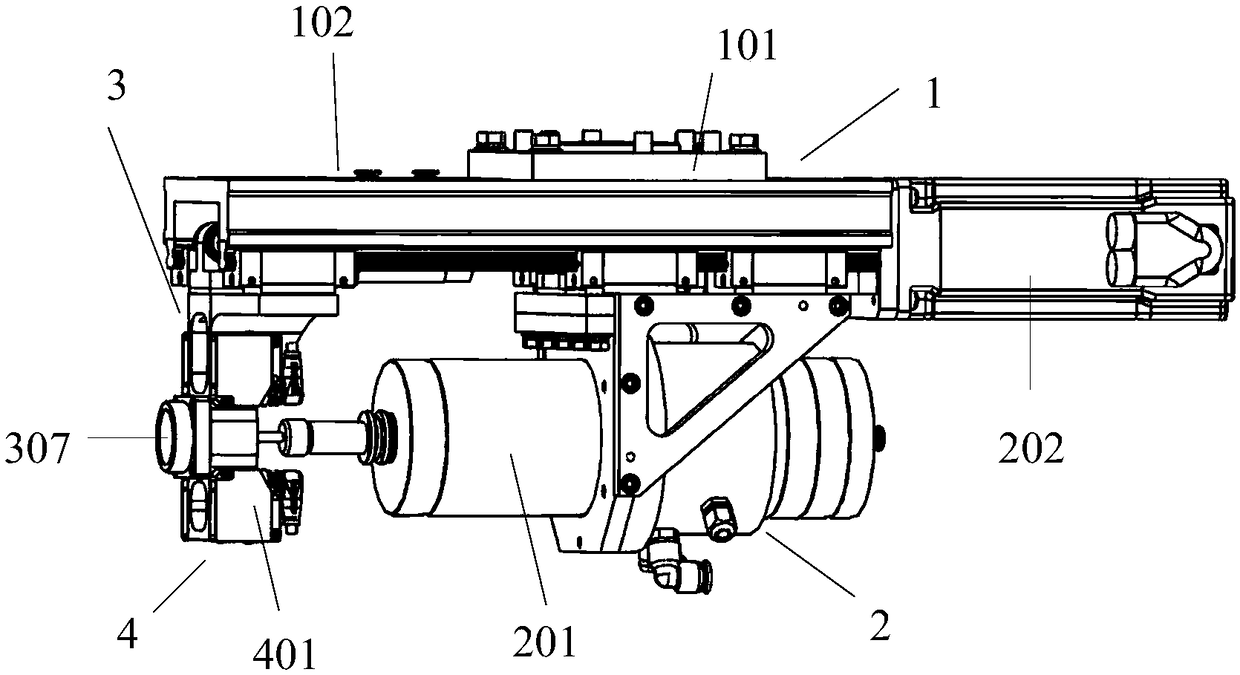

[0024] see figure 1 As shown, the present invention relates to a compact hole-making end effector in which an electric spindle and a pressure foot share a guide rail. The end effector includes a frame module 1 , a hole-making module 2 , a pressure foot module 3 , and a normal detection module 4 .

[0025] The frame module 1 is the support of the entire end effector; the hole making module 2 and the pressure foot module 3 are installed on the frame module 1 ; the normal detection module 4 is installed on the pressure foot module 3 .

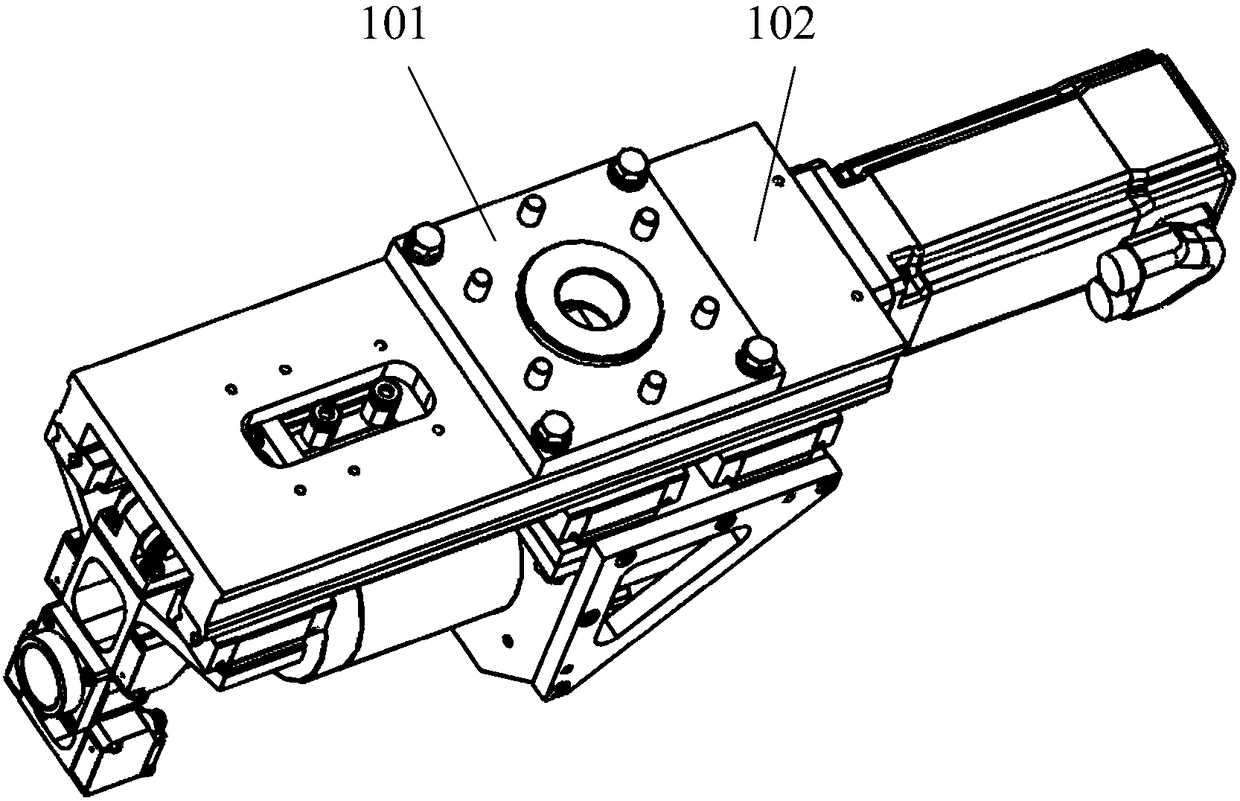

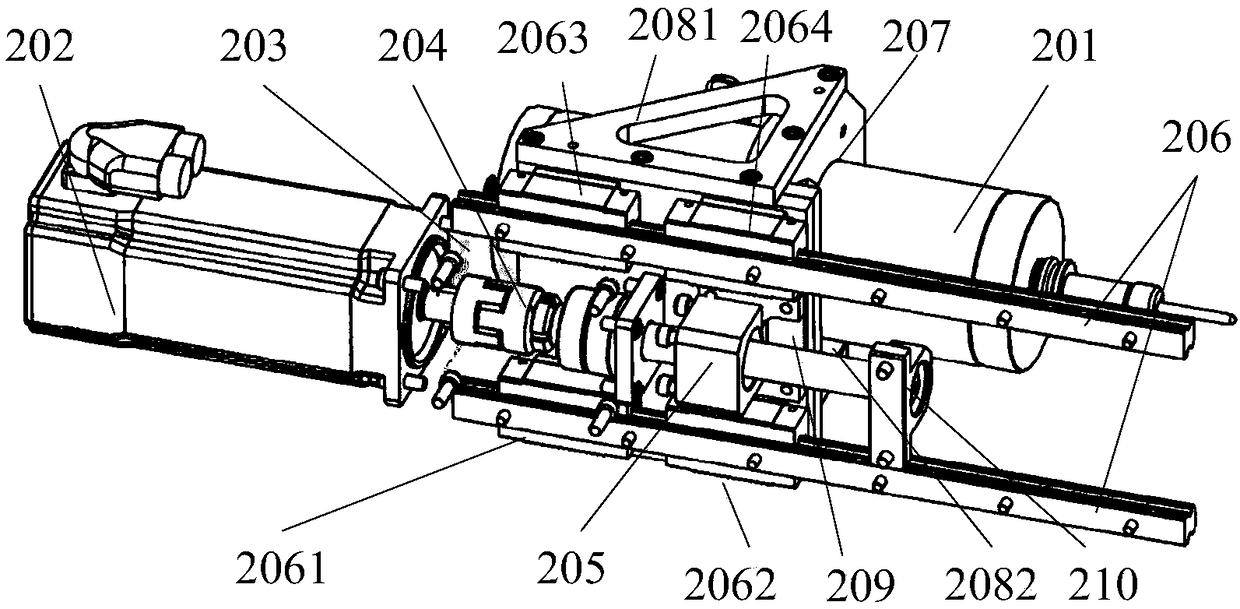

[0026] see figure 2 As shown, the frame module 1 includes a flange connection plate 101 and a main frame 102 . The flange connection plate 101 is fixed on the upper surface of the main frame 102 , and two parallel guide rails 206 are erected on the two side ends on the lower surface of the main frame 102 . The central axis of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com