Weight counterbalance control system of automatic packaging production line for cathode copper plates

A technology of automatic packaging and control system, applied in the field of machinery, can solve the problems of low degree of automation, high labor intensity, low production efficiency, etc., to achieve the effect of high degree of automation, improve production efficiency, and reduce the number of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

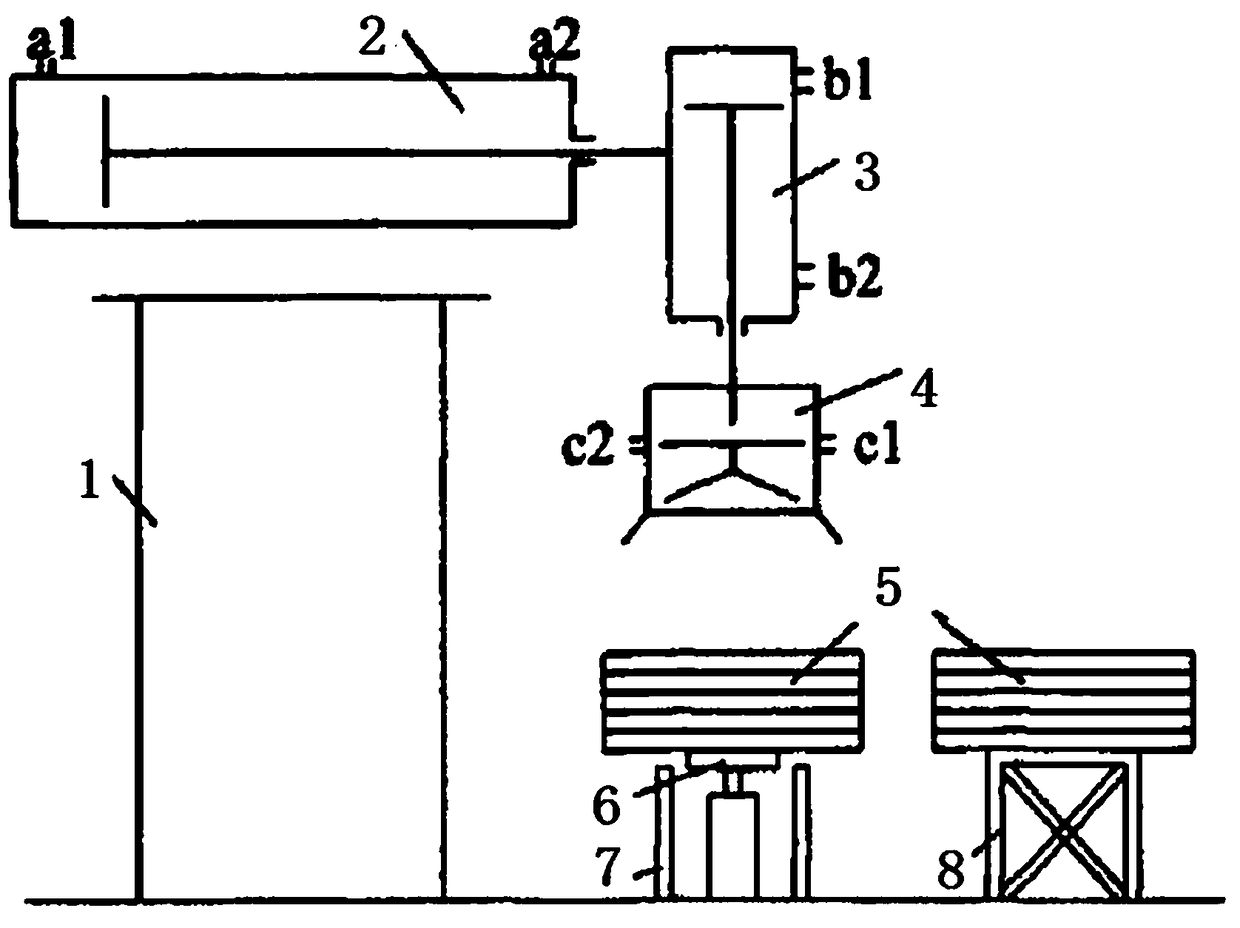

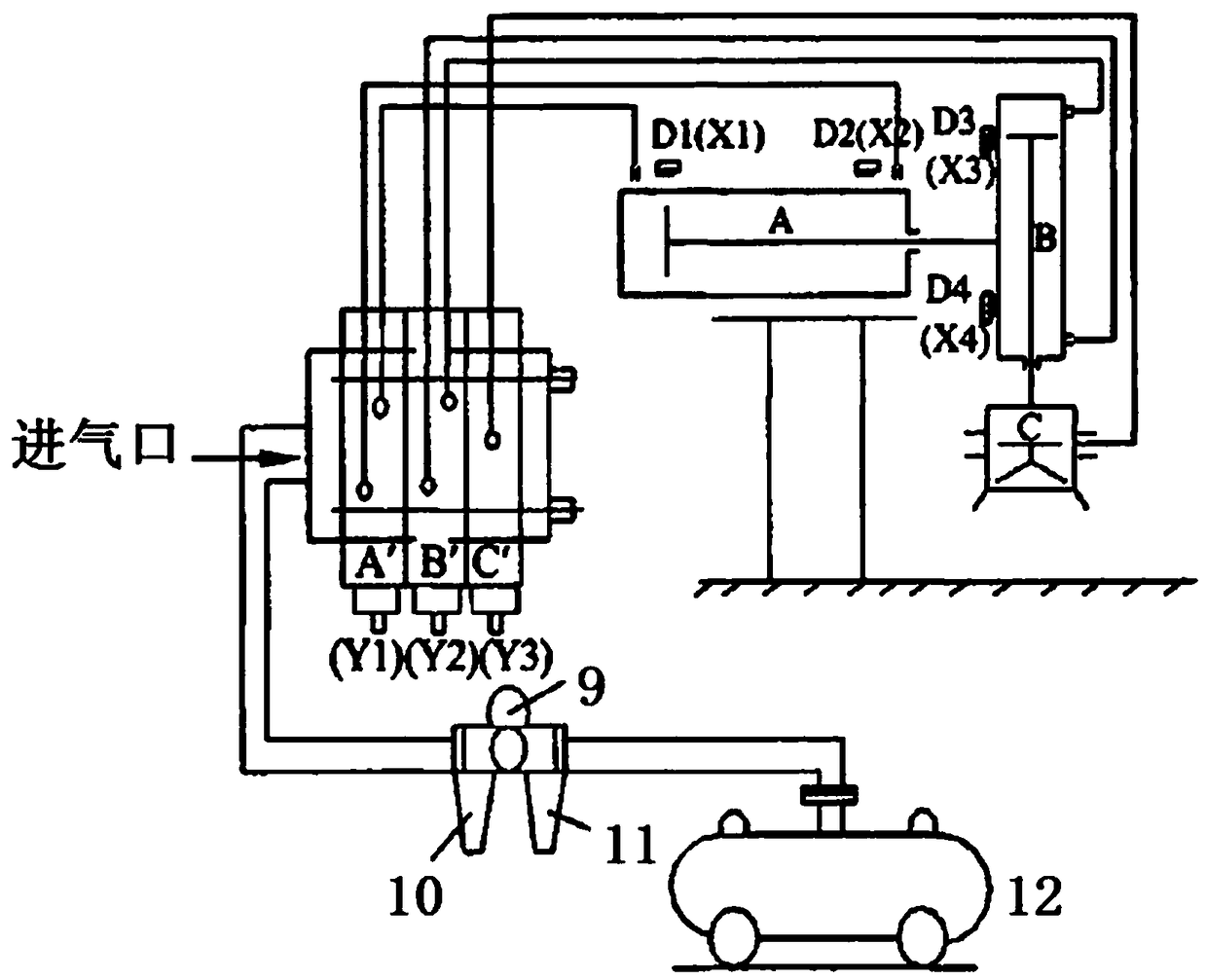

[0015] Such as figure 1 , the counterweight mechanical system is mainly composed of a vacuum suction cup with a vacuum generator, a horizontal cylinder A, a vertical cylinder B and a bracket; an electronic scale for weighing the weight of a single stack of copper plates is placed on the counterweight station of the copper plate conveying line. On the right side is the storage platform for storing copper plates.

[0016] Horizontal cylinder A performs left and right horizontal movement; vertical cylinder B performs up and down vertical movement, and vacuum generator C controls the suction and opening of the suction cup. a1, a2, b1, b2, c1, c2 are the intake and exhaust ports of cylinders A and B and vacuum generator C respectively.

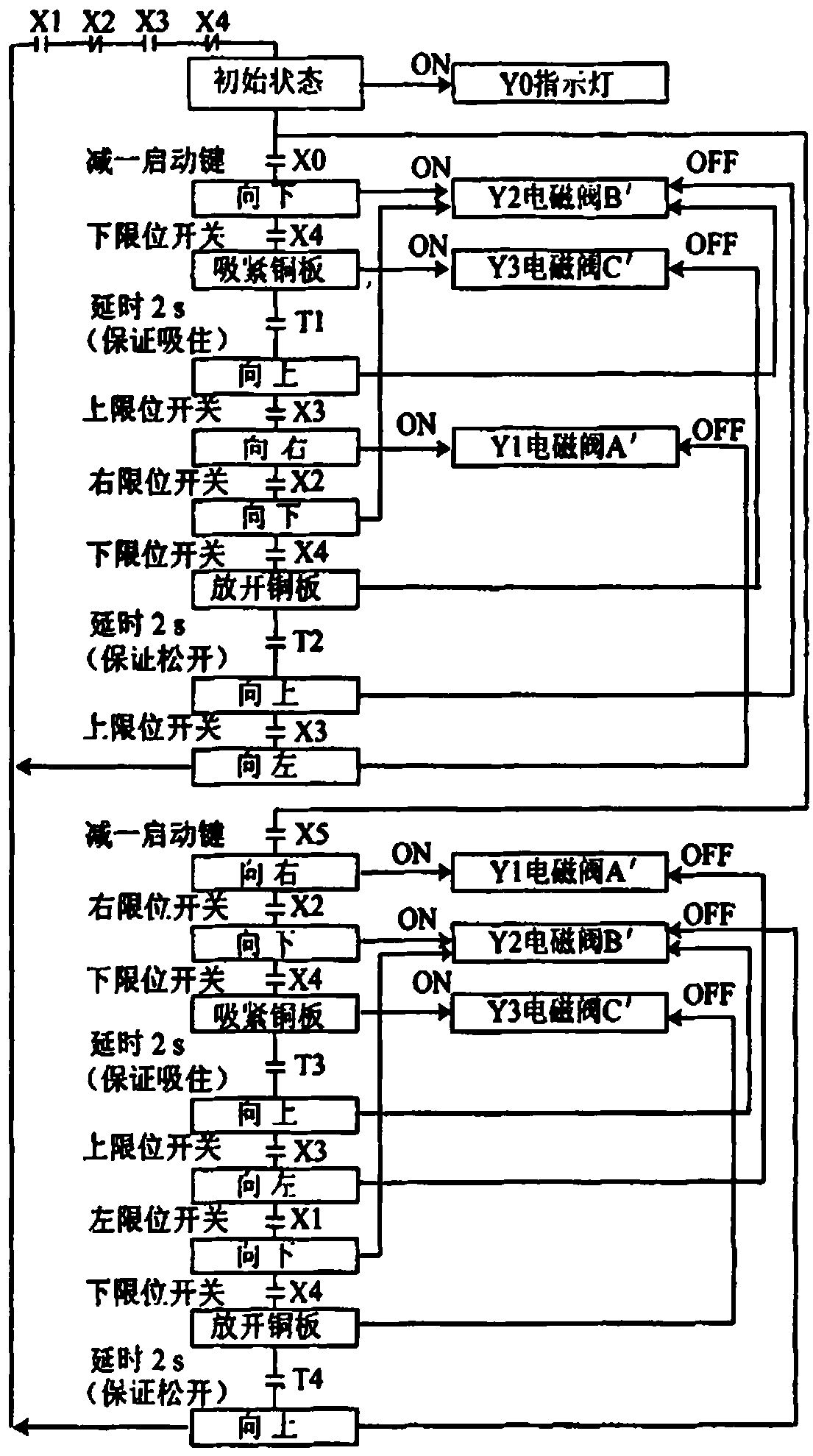

[0017] According to the counterweight principle of a single stack of copper plates, according to the measurement results of the electroni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com