Repair material for quickly repairing pavement as well as preparation method and application thereof

A repair material and fast technology, applied in the field of building materials, can solve the problems of materials not suitable for repair in extremely cold areas, low cement concrete bonding force, long construction time, etc., to achieve shortened open traffic time, high fluidity, fast and effective repair Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

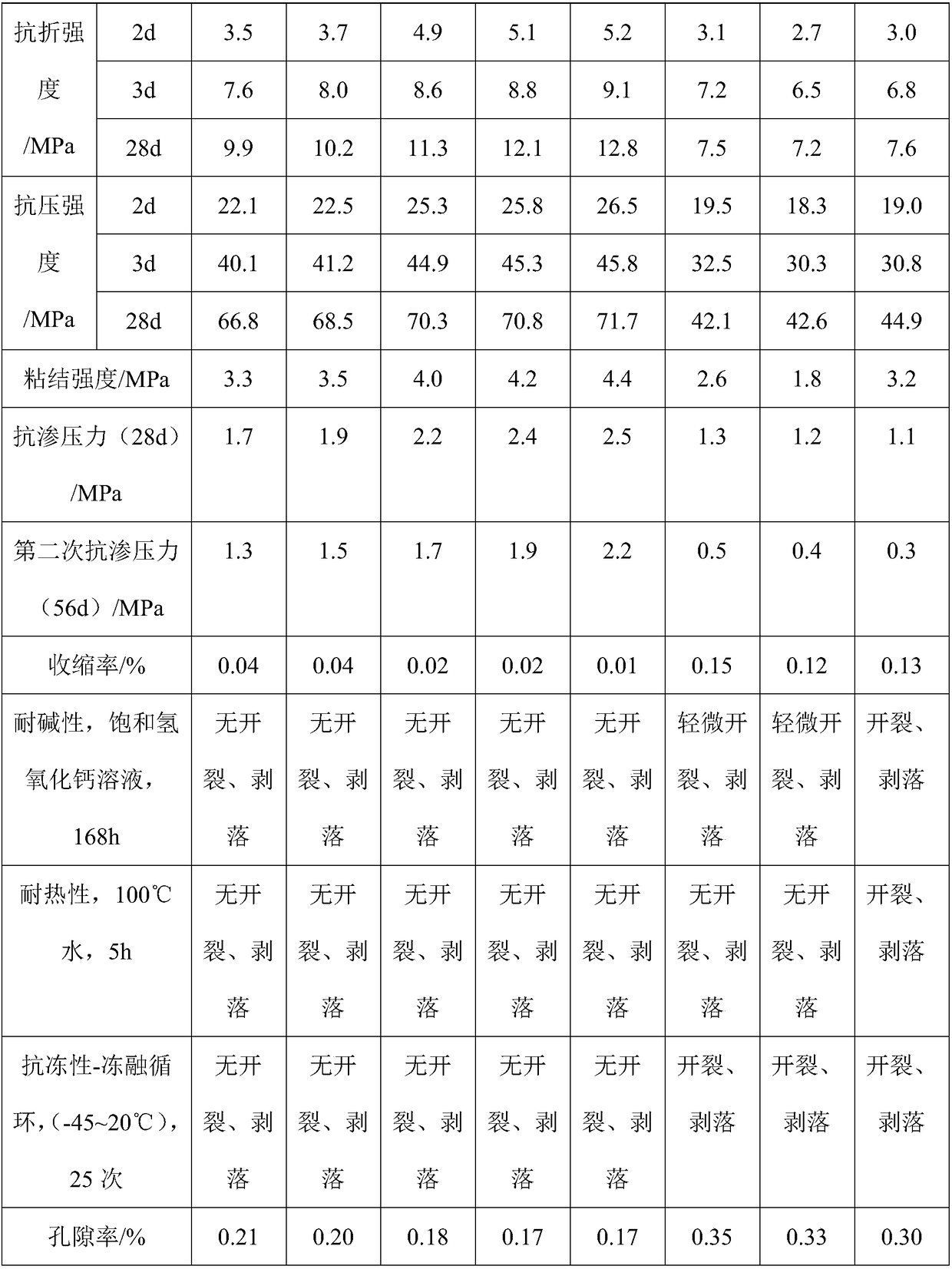

Examples

Embodiment 1

[0018] In the embodiment of the present invention, a repairing material for quickly repairing road surfaces comprises the following raw materials: Portland cement 38kg, fine sand 17kg, vinyl acetate resin 9kg, polyoxyethylene ether 3kg, bran 13kg, hexamethylenetetramine 15kg.

[0019] Mix the hexamethylenetetramine with water whose mass is 4.5 times that of the hexamethylenetetramine solution for future use. Mix the vinyl acetate resin and bran and pulverize it, raise the temperature to 58°C, heat and stir at this temperature for 20 minutes, then raise the temperature to 76°C, add the hexamethylenetetramine solution, and heat and stir at 76°C for 0.9h. A mixture is prepared. Mix Portland cement, fine sand, and polyoxyethylene ether evenly, then add the mixture, and stir for 1.9 hours to obtain the repair material. The stirring temperature when adding the mixture was 50°C.

Embodiment 2

[0021] In the embodiment of the present invention, a repairing material for quickly repairing road surfaces comprises the following raw materials: 46 kg of Portland cement, 25 kg of fine sand, 17 kg of vinyl acetate resin, 7 kg of polyoxyethylene ether, 21 kg of bran, and hexamethylenetetramine 25kg.

[0022] Mix hexamethylenetetramine with water with 5 times its mass to prepare a hexamethylenetetramine solution for future use. Mix the vinyl acetate resin and bran and pulverize it, raise the temperature to 62°C, heat and stir at this temperature for 25 minutes, then raise the temperature to 76°C, add hexamethylenetetramine solution, and heat and stir at 76°C for 1 hour to prepare Get the mix. Mix Portland cement, fine sand, and polyoxyethylene ether evenly, then add the mixture, and stir for 2 hours to obtain the repair material. The stirring temperature when adding the mixture was 55°C.

Embodiment 3

[0024] In an embodiment of the present invention, a repairing material for quickly repairing road surfaces comprises the following raw materials: 40 kg of Portland cement, 19 kg of fine sand, 11 kg of vinyl acetate resin, 4 kg of polyoxyethylene ether, 15 kg of bran, and hexamethylenetetramine 18kg.

[0025] Mix hexamethylenetetramine with water with 5 times its mass to prepare a hexamethylenetetramine solution for future use. Mix the vinyl acetate resin and bran and pulverize it, raise the temperature to 60°C, heat and stir at this temperature for 25 minutes, then raise the temperature to 76°C, add hexamethylenetetramine solution, and heat and stir at 76°C for 1 hour to prepare Get the mix. Mix Portland cement, fine sand, and polyoxyethylene ether evenly, then add the mixture, and stir for 2 hours to obtain the repair material. The stirring temperature when adding the mixture was 52°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com