Making method of through marble tiles

A production method and marble technology, applied in the field of ceramic tile production, can solve the problems of complex process, limited recognition in the terminal market, and high production cost, and achieve the effects of excellent wear resistance and hardness, realistic effect, and improved product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

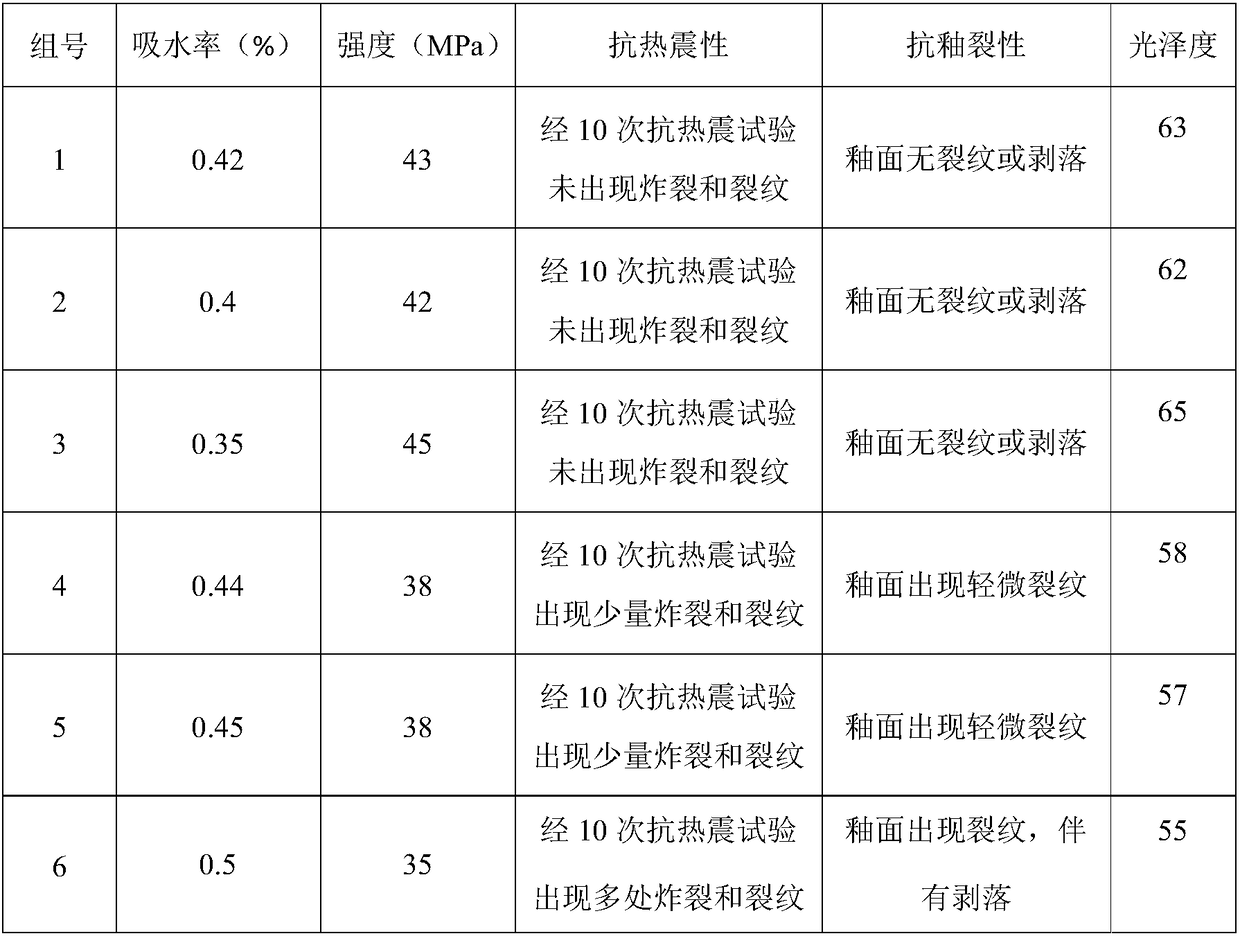

Examples

Embodiment 1

[0022] This embodiment provides a method for making a whole body marble tile, comprising:

[0023] Measure the blank with a fineness of 1.5mm at a flow rate of 25s to make a blank with a moisture content of 0.05%; divide the glaze with a fineness of 0.025mm into a bottom glaze and a top glaze; After the flow rate of 62s is applied to the primer, after printing, a layer of layer glaze is applied at the flow rate of 62s; after the glaze is applied, the finished product is fired at 1245°C for 75 minutes to obtain the product.

Embodiment 2

[0025] This embodiment provides a method for making a whole body marble tile, comprising:

[0026] The blank with a fineness of 2mm is measured at a flow rate of 40s to make a blank with a moisture content of 0.1%; the glaze with a fineness of 0.035mm is divided into a bottom glaze and a top glaze; Apply the base glaze at the flow rate, and after printing, apply a layer of glaze at the flow rate of 65s; after the glaze is applied, the finished product is fired at 1250°C for 65 minutes to obtain the product.

Embodiment 3

[0028] This embodiment provides a method for making a whole body marble tile, comprising:

[0029] Measure the blank with a fineness of 1.8mm at a flow rate of 30s to make a blank with a moisture content of 0.08%; divide the glaze with a fineness of 0.03mm into a bottom glaze and a top glaze; After the flow rate of 64s is applied to the undercoat, after printing, a layer of glaze is applied at a flow rate of 64s; after the application of the glaze, the finished product is fired at 1248°C for 70 minutes to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com