(2m, m) carbon nano tube horizontal array and preparation method thereof

A carbon nanotube, horizontal technology, applied in the field of carbon nanotube horizontal array and its preparation, can solve the problems of low growth efficiency, non-horizontal array, poor quality of carbon nanotubes, etc., and achieve high activity and high array effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

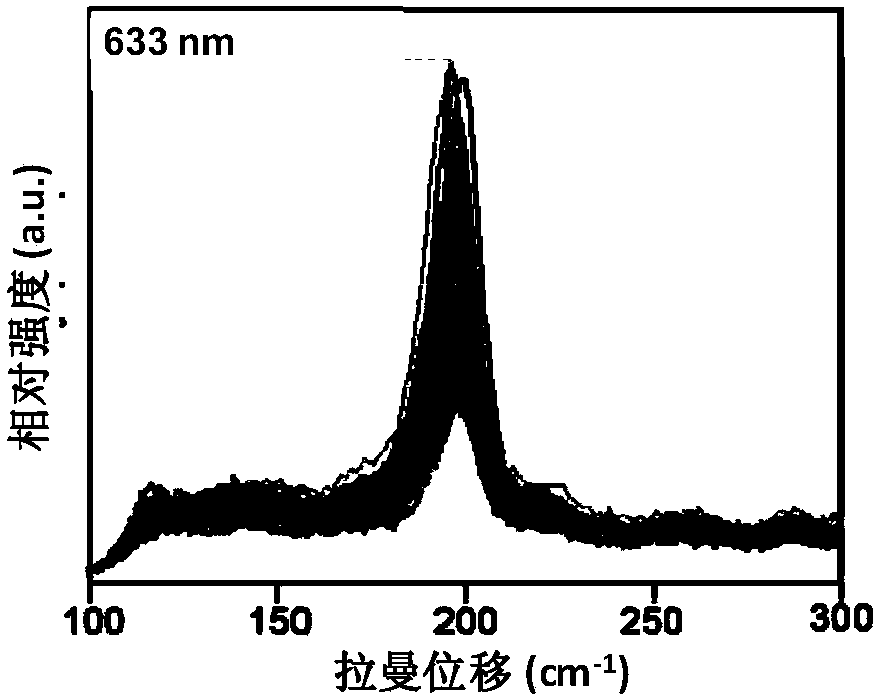

[0055] Embodiment 1, preparation (12,6) carbon nanotube horizontal array

[0056] in 4×6mm 2 On the single crystal α-alumina substrate, spin-coat a 0.05mM ethanol solution of ammonium molybdate on the single crystal substrate at a speed of 2500r / min, and then anneal at 1100°C for 8 hours to allow the catalyst precursor molybdenum Ammonium phosphate is fully oxidized and spread on a single crystal alumina substrate. The annealed substrate was placed in a reaction vessel at 450°C and reduced with 200 sccm of hydrogen for 10 minutes, and then raised to 850°C; the hydrogen was stopped, and 100 sccm of ethanol vapor (carried by argon) was introduced to grow for 30 minutes, and then the temperature was lowered to obtain 15 A root (12,6) carbon nanotube horizontal array, wherein the diameter of the carbon nanotube is 1.1-1.3 nm, and the length is 100-300 μm.

[0057] The chiral selectivity of the (12,6) carbon nanotube horizontal array prepared in this example reaches 90%.

[0058...

Embodiment 2

[0062] Embodiment 2, preparation (8,4) carbon nanotube horizontal array

[0063] in 4×6mm 2 On the single crystal α-alumina substrate, spin-coat 0.05mM ethanol solution of ammonium tungstate on the single crystal substrate at a speed of 2500r / min, and then anneal at 1000°C for 8 hours, so that the catalyst precursor tungsten Ammonium phosphate is fully oxidized and spread on a single crystal alumina substrate. The annealed substrate was placed in a reaction vessel at 800°C and reduced with 200 sccm of hydrogen for 5 minutes, and then raised to 850°C; the hydrogen was stopped, and 100 sccm of ethanol vapor (carried by argon) was introduced to grow for 15 minutes, and then the temperature was lowered to obtain 10 The root (8,4) carbon nanotube horizontal array, wherein the diameter of the carbon nanotube is 0.7-1.0 nm, and the length is 100-300 μm.

[0064] The chiral selectivity of the (8,4) carbon nanotube horizontal array prepared in this example reaches 80%.

[0065] The ...

Embodiment 3

[0068] The mechanism analysis of the catalyst preparation of embodiment 3, (2m, m) single-walled carbon nanotube horizontal array;

[0069] 1. Mechanism analysis and verification of catalyst monodisperse preparation of (2m, m) single-walled carbon nanotube horizontal arrays;

[0070] Carry out AFM surface analysis with spin-coated ammonium molybdate-loaded ammonium molybdate annealing obtained after the embodiment 1, as Figure 8 as shown, Figure 8 a) is the AFM image of the initial spin-coated ammonium molybdate precursor, after annealing, all disappear and disperse on the surface of the single crystal substrate, such as Figure 8 As shown in b), AFM shows hardly any catalyst particles on the surface of the substrate after annealing.

[0071] To further demonstrate the monodisperse process of catalyst precursors, different concentrations of ammonium molybdate were spin-coated on single crystal substrates, as Figure 9 As shown in a), 9b) and 9c), it can be seen that as th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap