Underground storage tank structure for liquefied natural gas and construction method thereof

A technology for liquefied natural gas and underground storage tanks, which is applied in the field of liquefied natural gas underground storage tank structure and its construction, can solve the problems of LNG underground storage tank technology and lack of development, solve the problem of tank structure cracking, improve engineering economic benefits and Social and economical benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

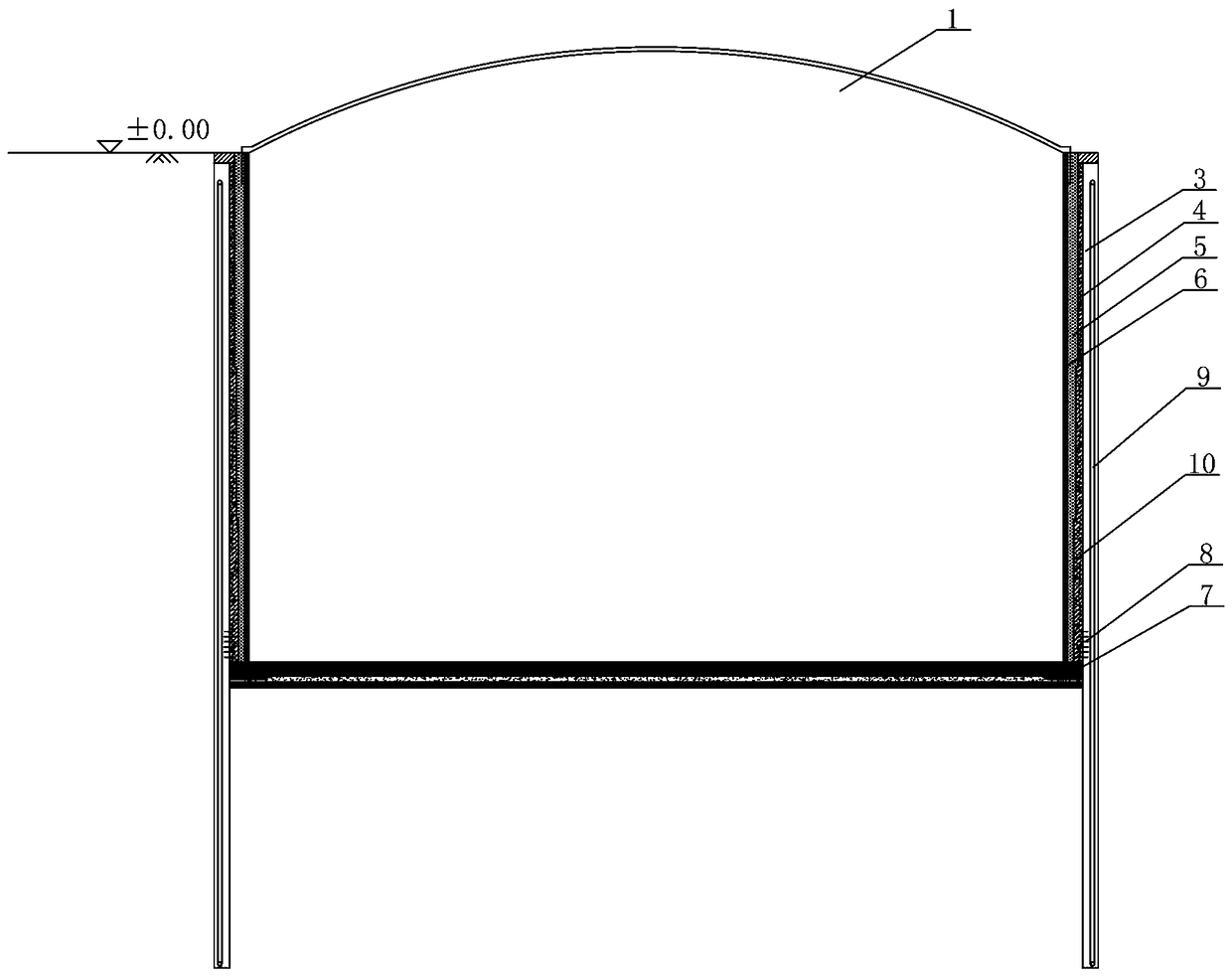

[0023] Through calculation and analysis, it is determined that the thickness of the underground diaphragm wall 3 is 1.5m, and the insertion depth is 30.0m. The specific construction is carried out according to the following steps:

[0024] (1) Construction of foundation pit enclosure structure

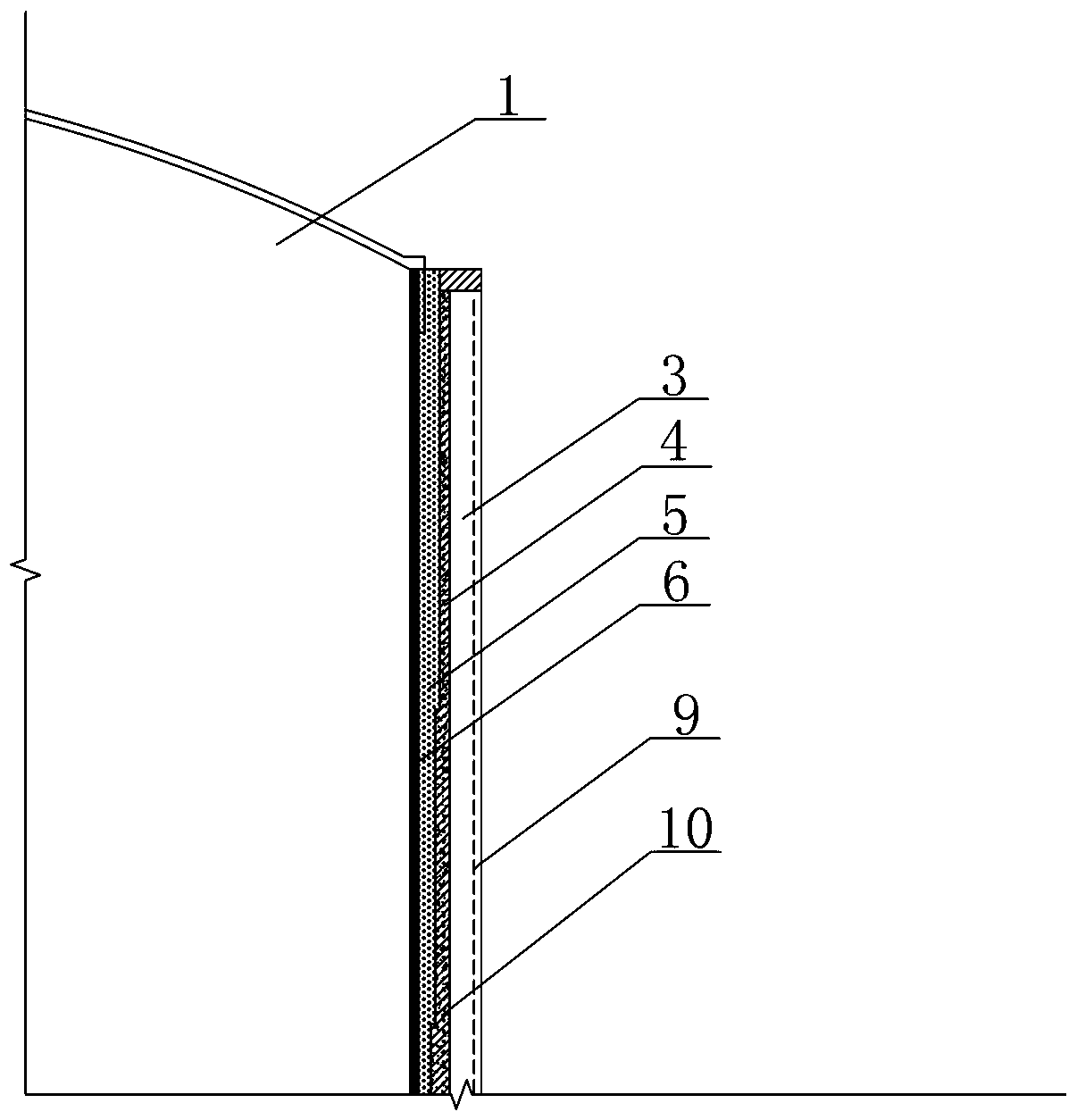

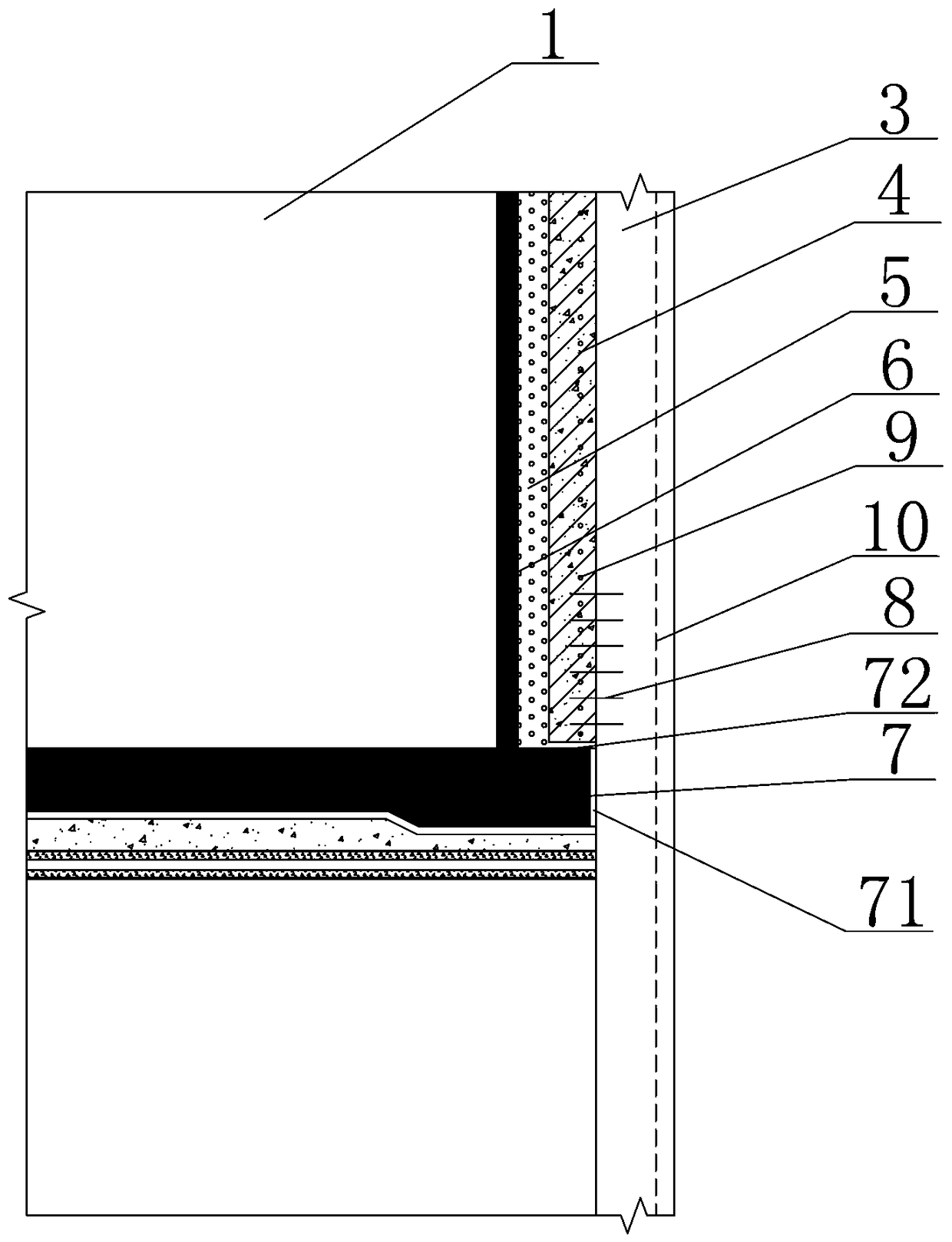

[0025] The construction of the underground diaphragm wall 3 includes trough forming, steel cage fabrication and hoisting, layout and embedding of embedded parts (wall bottom grouting pipelines, wall side grouting pipelines and lining connecting steel bars), underwater concrete pouring and other processes. Combined with the technical requirements of the outer tank of the LNG underground storage tank 1, the grouting pipe 9 is pre-embedded in the underground diaphragm wall 3, and the corresponding steel bar stress sensor is pre-embedded in the steel cage.

[0026] (2) Construction of inner wall

[0027] See attached figure 2 , the inner lining wall 4 is stepped and the tank body insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com