Arc-shaped rail driving guiding system

A technology of guiding system and arc-shaped track, which is applied in the direction of transmission device, friction transmission device, belt/chain/gear, etc., can solve the problems of difficult manufacturing, high cost, and very high processing accuracy of the base surface, so as to reduce the difficulty of processing and processing cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

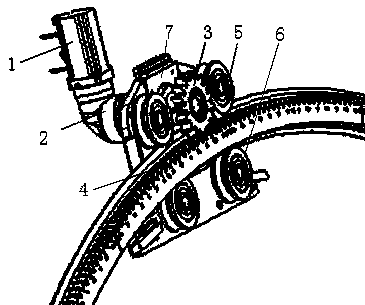

[0008] Such as figure 1 As shown, the present invention is an arc track driving and guiding system, which is characterized in that it includes a private motor 1, a reducer 2, a driving gear 3, a V-shaped guide rail rack 4, a centering V-shaped wheel 5, and an eccentric V-shaped wheel 6. The servo motor 1 is connected to the drive gear 3 through the reducer 2, the drive gear 3 meshes with the V-shaped rail rack 4, and the centering V-shaped wheel 5 and eccentric V-shaped wheel 6 are installed on the reducer bracket 7, the centering V-shaped wheel 5 is in contact with the upper part of the V-shaped guide rail rack 4, and the eccentric V-shaped wheel 6 is in contact with the lower part of the V-shaped guide rail rack 4.

[0009] When working, the private server motor 1 passes through the reducer 2 to make the drive gear 3 drive its accessory parts to move along the guide rail on the V-shaped guide rail rack 4 to realize the driving and guiding functions, and adjust the V-shaped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com