Internal spray oil-water isolation rotary sealing system of multistage mechanical sealing type coal mining machine

An oil-water isolation and mechanical sealing technology, applied in the direction of engine sealing, slitting machinery, mechanical equipment, etc., can solve problems such as increased wear and seal failure, and achieve the effect of improving safety and life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

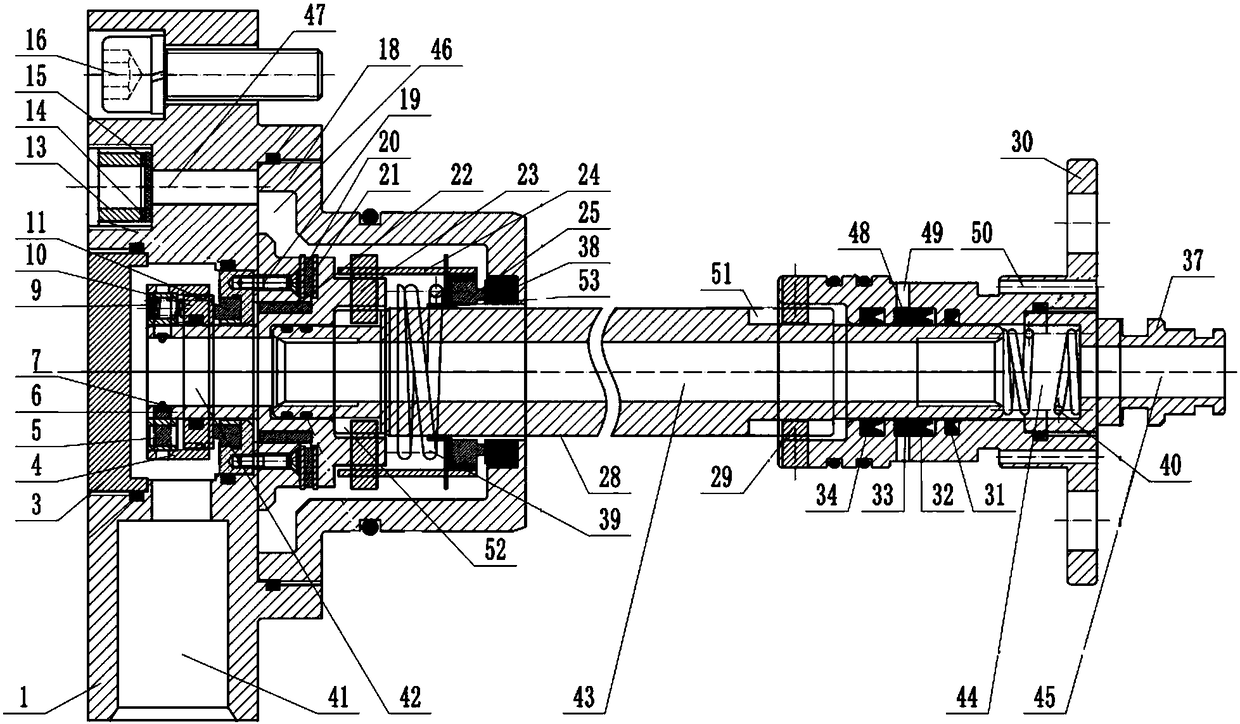

[0031] A multi-stage mechanical seal type coal shearer internal spray rotary sealing system, comprising a housing 1, a water pipe 28, and a pipe shaft seat 30, characterized in that: a threaded hole 16 and a plug are provided on one end surface of the housing 1 The cover 3 and the housing 1 are provided with a water inlet chamber 41, a rotary water seal drain hole 47, a primary seal dynamic ring 10 and a primary seal static ring 11, and one end of the rotary water seal drain hole 47 is provided with a hollow The screw plug 13, the hollow screw plug 13 is provided with a gasket 14 and a rubber pad 15 inside; the first-level sealing static ring 11 and the first-level sealing dynamic ring 10 form a friction pair seal;

[0032] The inline shaft sleeve 6 is connected to the first-stage sealing moving ring 10 through a sealing ring and driven by the inner teeth of the outer coupling shaft sleeve 4. The inline shaft sleeve 6 is connected and sealed with the water pipe 28 through a sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com